Three-dimensional wave coaxial motor-driven loudspeaker

A technology of electric speakers and stereo waves, applied in the field of speakers, can solve the problems of small speakers with large speakers, narrow sound fields, and large size disparity, etc., and achieve the effect of high electric-acoustic conversion efficiency, strong impact, and pure timbre

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

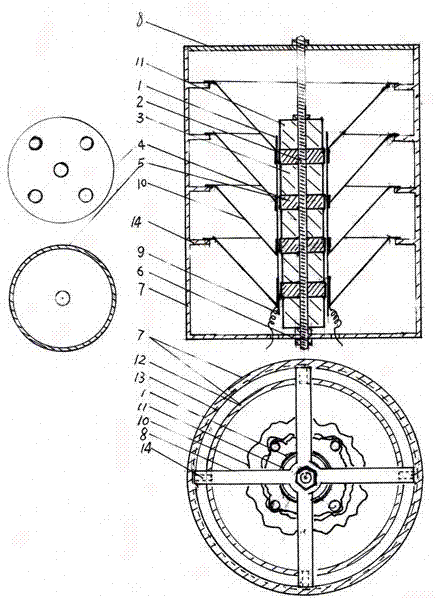

[0023] Such as figure 1 As shown, it is a coaxial stereo wave electric speaker with m diaphragms in the same direction. The upper end of the sound cone frame 7 is fixed with a positioning frame 8, the bottom of the sound cone frame 7 and the shaft center of the positioning frame 8 fix the screw rod 2, and the screw rod 2 is connected in series with a magnetic body composed of a magnet 3 and a separator 4 or an I-shaped casing 5 nut 6. Column 11. A separator 4 or an I-shaped sleeve 5 is placed between the magnets 3 of the same sex on the magnetic column 11, and corresponds to the voice coils on the voice coil set 1 one by one, and each voice coil has the same or different impedance, or is connected in parallel or in series, or can be connected in a push-pull connection. The voice coil group 1 is set on the outside of the magnetic column (body), and the audio power amplifier is directly passed through the spiral rubber tube wire 9 (during which, all kinds of frequency dividers...

Embodiment 2

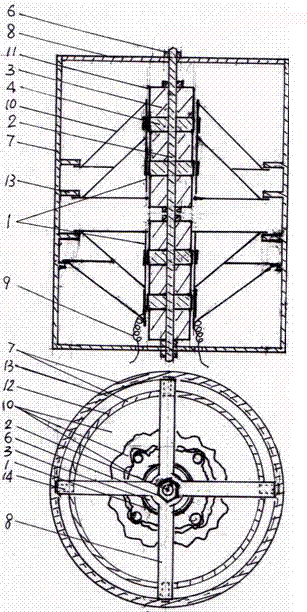

[0025] Such as figure 2 As shown, there are m coaxial stereo wave electric speakers with diaphragms facing each other. The upper end of the sound cone frame 7 is fixed with a positioning frame 8, the bottom of the sound cone frame 7 and the axis center of the positioning frame 8 are fixed with a screw 2, and the screw 2 is connected in series with a magnet 3 and a separator 4 or an I-shaped casing 5 and a nut 6. Magnetic column 11. A separator 4 or an I-shaped sleeve 5 is placed between the magnets 3 of the same sex on the magnetic column 11, and corresponds to the voice coils on the voice coil set 1 one by one, and each voice coil has the same or different impedance, or is connected in parallel or in series, or can be connected in a push-pull connection. The voice coil group 1 is set on the outside of the magnetic column (body), and the audio power amplifier is directly passed through the spiral rubber tube wire 9 (during which, all kinds of frequency dividers are avoided)...

Embodiment 3

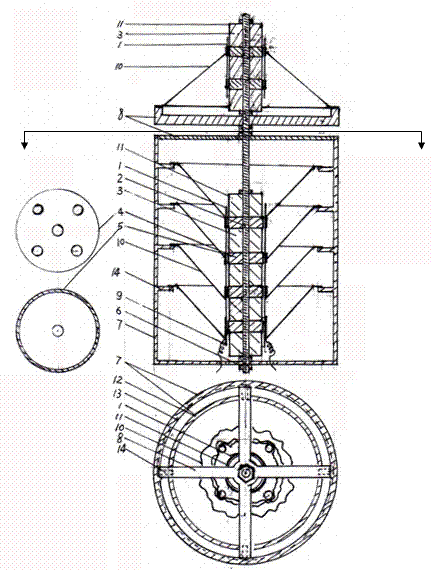

[0027] Such as image 3 As shown, the hybrid m-diaphragm coaxial stereo wave dynamic loudspeaker. The upper end of the sound cone frame 7 is fixed with a positioning frame 8, the bottom of the sound cone frame 7 and the axis center of the positioning frame 8 are fixed with a screw 2, and the screw 2 is connected in series with a magnet 3 and a separator 4 or an I-shaped casing 5 and a nut 6. Magnetic column 11. A separator 4 or an I-shaped sleeve 5 is placed between the magnets 3 of the same sex on the magnetic column 11, and corresponds to the voice coils on the voice coil set 1 one by one, and each voice coil has the same or different impedance, or is connected in parallel or in series, or can be connected in a push-pull connection. The voice coil group 1 is set on the outside of the magnetic column (body), and is directly connected to the audio power amplifier through the spiral rubber tube wire 9 (during which, various frequency dividers are also prevented). The m diaph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com