an image sensor

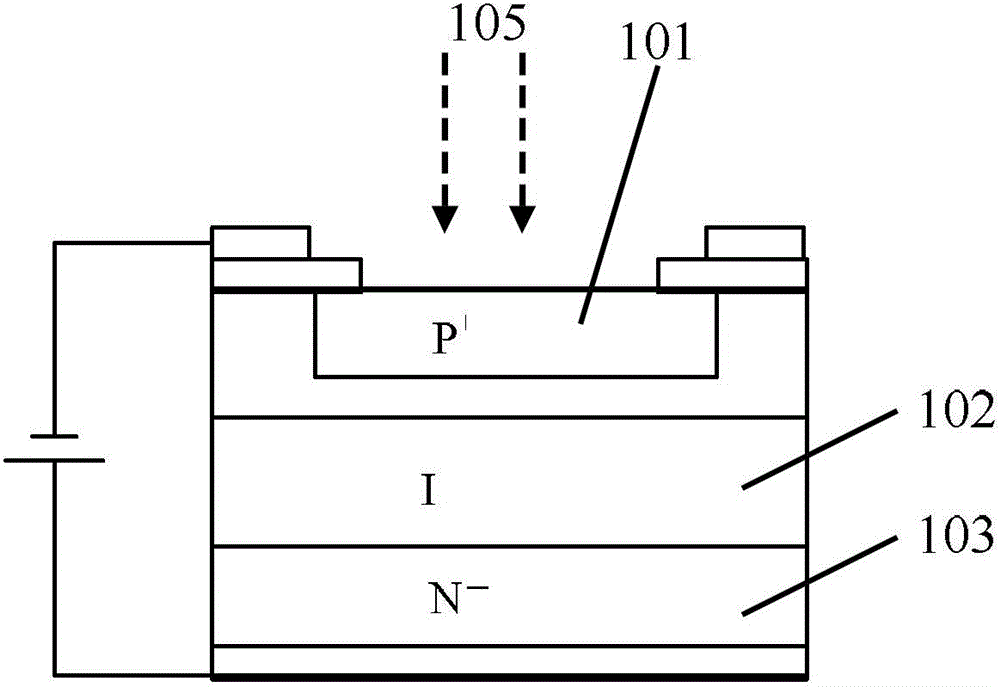

An image sensor and optical sensor technology, applied in the field of image sensors, can solve the problems of increasing imaging signal residue, slow readout speed of photoelectric signal, and affecting dark current performance, etc., so as to reduce imaging signal residue, difficulty and risk small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

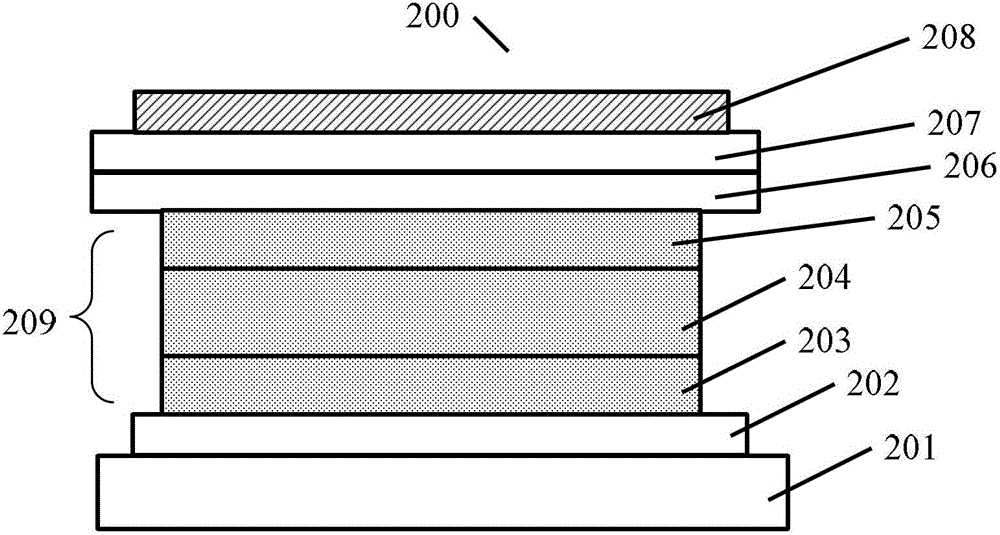

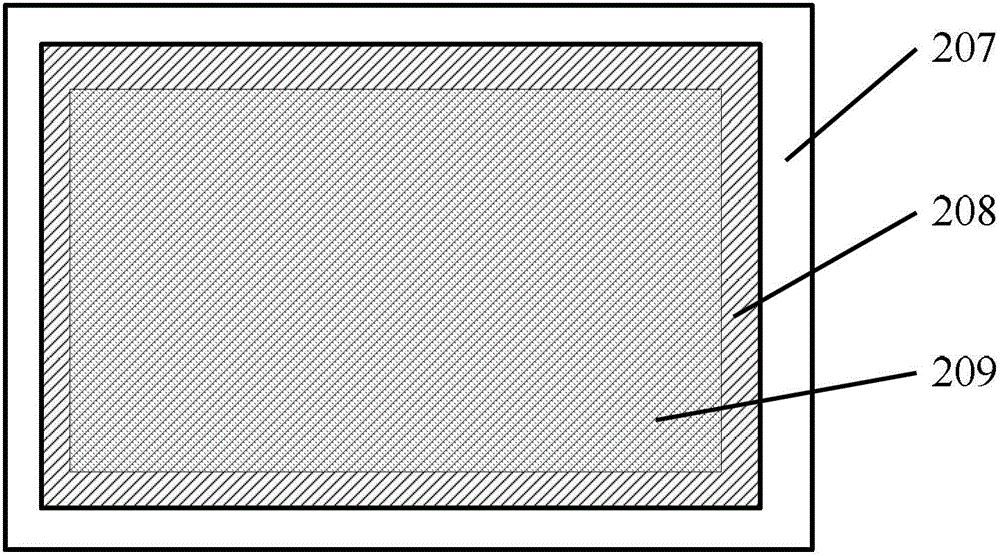

[0068] Figure 2-3 A first embodiment of the invention is shown.

[0069] figure 2 is a schematic structural diagram of the image sensor 200 according to the first embodiment of the present invention, as figure 2 As shown, the image sensor 200 in this embodiment includes: a substrate 201 , a top electrode layer 206 , a common electrode layer 207 , a photodiode structure layer 209 , a bottom electrode layer 202 and an adjustment layer 208 . Wherein, the photodiode structure layer 209 is arranged between the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com