Crystal boundary density measuring method

A technology of density measurement and grain boundary length, which is applied in the field of metallographic inspection, can solve the problems of small number of grains and low measurement accuracy, and achieve the effect of improving measurement accuracy and avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

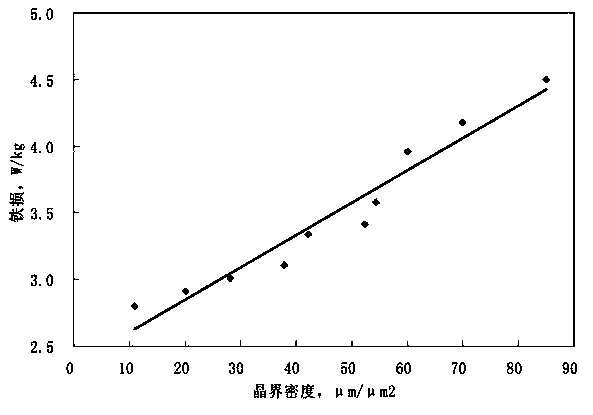

[0019] Take some pieces of 50W470 grade cold-rolled non-oriented silicon steel cold-rolled plates, and process them into Ebstein square circle samples. The iron loss properties were measured after the samples were subjected to the following heat treatments.

[0020] Table 1 Heat treatment process and performance

[0021] Sample No.

Holding time, s

Iron loss, W / kg

11

900

210

2.80

12

900

150

3.01

13

900

100

3.34

14

900

55

3.58

15

900

40

3.96

21

880

190

2.91

22

880

130

3.11

23

880

80

3.41

24

880

40

4.18

25

880

20

4.50

[0022] First measure the iron loss performance of the sample, and then measure the grain boundary density. Analyze the relationship between grain and iron loss. The main steps for determining the grain boundary density are as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com