Roast billet high-speed sampling machine

A sampling machine and roasting technology, which is applied in the field of sampling machines, can solve problems such as unfavorable quality detection and control of cylindrical graphite electrode roasted blanks, affecting the quality stability of cylindrical graphite electrodes, and inability to perform physical and chemical analysis, so as to facilitate quality detection and control, The sampling process is safe and reliable, and it is convenient for physical and chemical analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

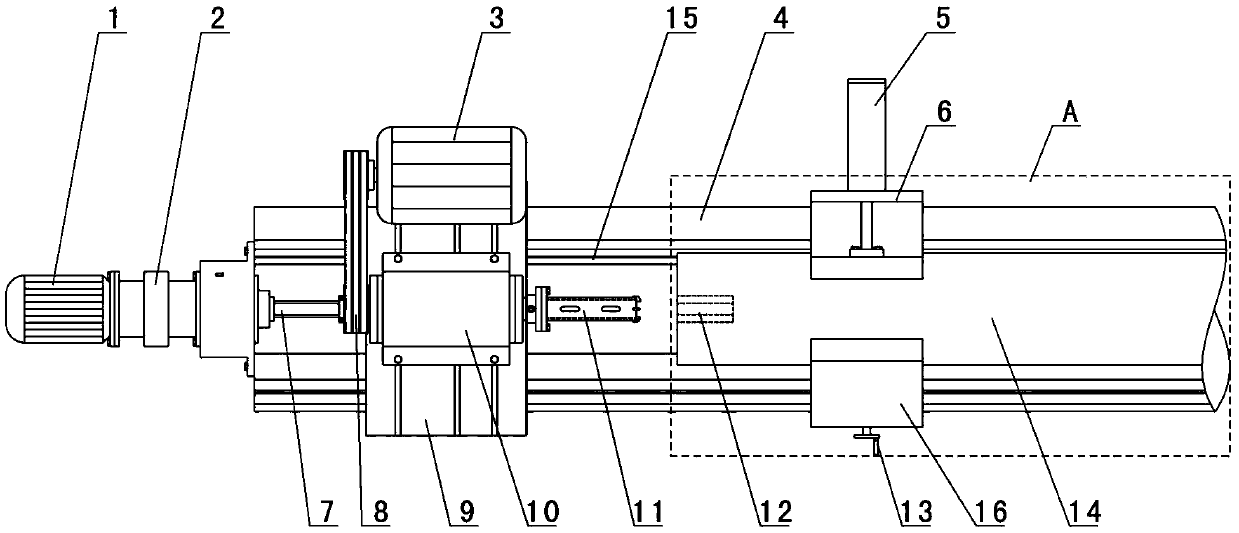

[0016] The present invention will be further described below in conjunction with accompanying drawing:

[0017] like figure 1 As shown, the right side of the figure is the fracture treatment, indicating that the length of the right part is determined according to actual needs. The roasted billet high-speed sampling machine of the present invention comprises a machine tool 4, a clamping device, a sampling cutter head 11, a cutter head rotation drive device, a sliding plate 9 and a cutter head moving drive device, and the machine tool 4 is provided with a roasted billet installation area A, so The clamping device is installed in the roasted billet installation area A on the machine tool 4; the clamping device includes a fixed clamping seat 16 and a driving clamping seat 6, and the fixed clamping seat 16 and the driving clamping seat 6 are arranged oppositely It is also used to clamp the roasted billet 14, the driving and holding seat 6 is driven by the cylinder 5, and the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com