Spraying nozzle cavitation flow nanosecond flash imaging test device and method

A flow nanosecond and nanosecond technology, which is applied in the fields of water conservancy machinery, aerospace, diesel engine fuel spray, chemical industry, navigation, and national defense, and can solve problems such as unsatisfactory shooting frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

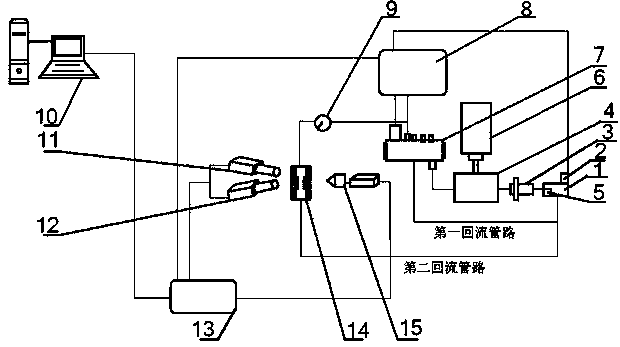

[0020] The structure of a nozzle cavitation flow nanosecond flash imaging test device of the present invention is as follows: figure 1 shown, including the test system and piping system, where:

[0021] The test system includes a common rail control system 8 , a computer 10 , a first CCD camera 11 , a second CCD camera 12 , a synchronizer 13 , and a nanosecond-level white light source flash system 15 . The synchronizer 13 is respectively connected with the common rail control system 8, the computer 10, the first CCD camera 11, the second CCD camera 12, and the nanosecond white light source flash system 15, and is used to control the high-speed nanosecond white light source flash system 15 to emit white light. Time and the shooting time of the first CCD camera 11 and the second CCD camera 12. The common rail control system 8 is also respectively connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com