Heating machine structure capable of improving sealing stability

A heater and stability technology, applied in the mechanical field, can solve problems such as seal failure, heater change, air pressure change, etc., to achieve the effect of improving sealing and solving seal failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

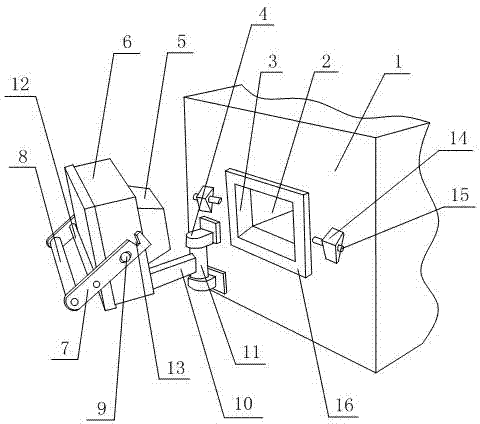

[0015] Such as figure 1 As shown, the heater structure capable of increasing the sealing stability includes a sealed casing 1, the side wall of the casing 1 is provided with a feed port 2 communicating with the inside of the casing 1, and a heat preservation device is sleeved in the feed port 2. Cover 16, heat preservation cover 16 is provided with through hole 3, and the side wall that is provided with feed port 2 on described housing 1 is provided with sealing block 5, and sealing block 5 is the trapezoidal body structure that fits with through hole 3, and sealing block 5 The side wall of the housing 1 is in seamless contact with the side wall of the through hole 3; the housing 1 is provided with two locking mechanisms on the side wall of the material opening 2, and the locking mechanisms are symmetrically arranged on both sides of the insulation cover 16. The tightening mechanism comprises a fixed block 14 and a locking pin 15, and the locking pin 15 passes through the fixi...

Embodiment 2

[0017] Such as figure 1 As shown, on the basis of Embodiment 1, two fixing buckles 4 are arranged on the side wall of the housing 1 provided with the feed port 2, the fixing buckles 4 are arranged on the same vertical line, and the fixing buckles 4 are arranged between There is a rotating shaft 11, the two ends of the rotating shaft 11 pass through one of the fixing buckles 4 respectively, and the rotating shaft 11 can rotate in the fixing buckle 4 around its axis, the outer wall of the rotating shaft 11 is fixed with a rotating handle 10, and the rotating handle 10 Arranged between the two fixing buckles 4 , the end of the rotating handle 10 away from the rotating handle 10 is fixed to the side wall of the spacer block 6 , and the fixing buckle 4 is arranged below the fixing block 14 . In order to be able to realize the rotation of the rotating handle 10 to drive the isolation block 6, and to insert the sealing block 5 into the through hole 3, a rotating mechanism needs to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com