Axial corrugated expansion joint with reinforced connection structure

A technology of connecting structure and bellows, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/fittings, pipe components, etc., can solve problems such as vulnerable welds, and achieve flexible compensation action, firm connection, and reduced The effect of liquid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

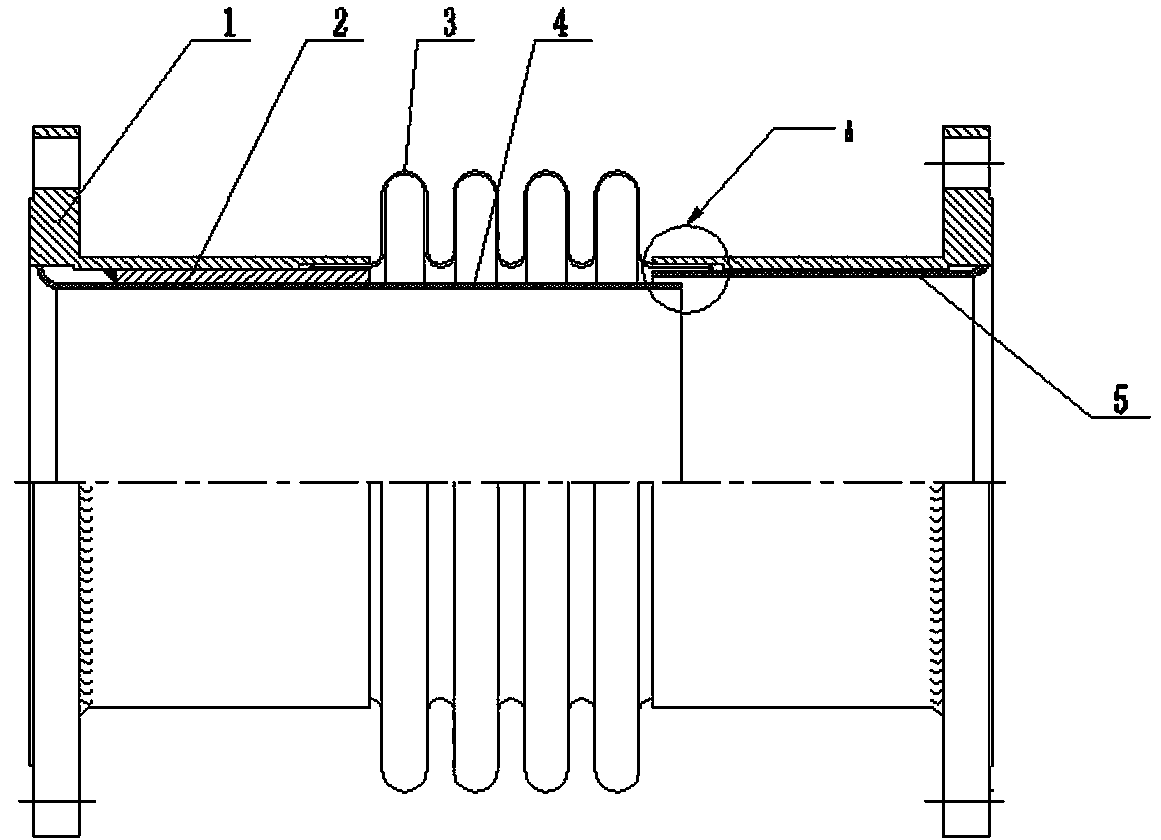

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

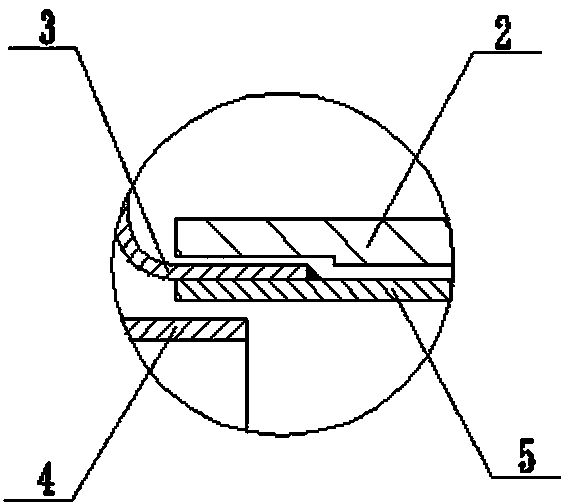

[0013] figure 1 The shown axial bellows compensator with strengthened connection structure is composed of connecting pipe 1 , left liner 2 , bellows 3 , guide tube 4 and right liner 5 . The straight edge sections at both ends of the bellows 3 are respectively set on the outer walls of the left liner 2 and the right liner 5, and the straight edges of the ring bellows 3 are used as sealing connections between fittings, and the formed parts are built-in elastic bodies in the present invention. , directly used to bear or compensate axial force and displacement. The connecting pipe 1 is a circular straight pipe with a flange at one end, which is not only an external connecting piece, but also has the function of a sheath. The connecting pipe 1 is respectively set on the outer wall of the left lining pipe 2 and the right lining pipe 5 which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com