A device for coupling a hard steel pipe and a viscoelastic pipeline to transmit liquid

A viscoelastic, steel pipe technology, applied in the direction of hose connection device, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problem of difficult to eliminate and control, difficult to adapt to the uneven and complex working conditions of underground roadway, large pressure drop, etc. problem, to achieve the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

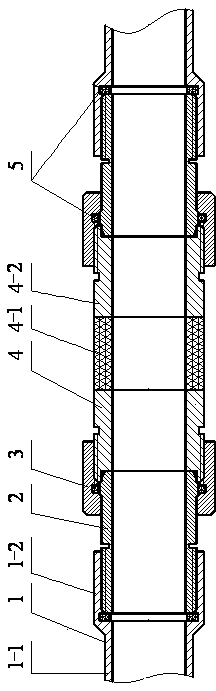

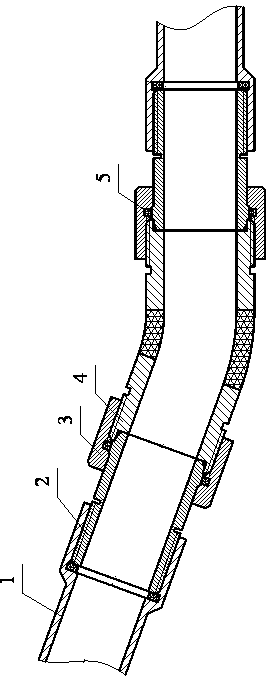

[0018] In the accompanying drawings, a device for coupling and transmitting liquid between a hard steel pipe and a viscoelastic pipeline, including a hard steel pipe 1 as the main body of liquid transmission, which is connected between two hard steel pipes 1 so that the pipeline can be freely bent and transformed The viscoelastic pipeline 4, and the pipeline joint 2 and buckle nut 3 to realize the connection between the hard steel pipe 1 and the viscoelastic pipeline 4; the hard steel pipe 1 includes a main pipe body 1-1 and two pipes connected to the main pipe body 1-1 The joint 1-2 at the end, the inner diameter of the joint 1-2 is larger than the inner diameter of the main body 1-1 and is provided with internal threads, and the joint between the main body 1-1 and the joint 1-2 is provided with a sealing ring 5 Groove; the viscoelastic pipeline 4 includes a freely bendable high-pressure rubber hose 4-1 located in the middle section, and the two ends of the high-pressure rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com