A combustion organization method and a combustion system

A technology of combustion system and structure, applied in the field of combustion system and combustion structure, can solve problems such as inability to suppress knocking, and achieve the effects of good industrialization prospects, efficient and clean combustion, and good anti-knock performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 of the present invention provides a combustion system to describe the specific implementation process of the embodiment of the present invention in detail, see Figure 4 :

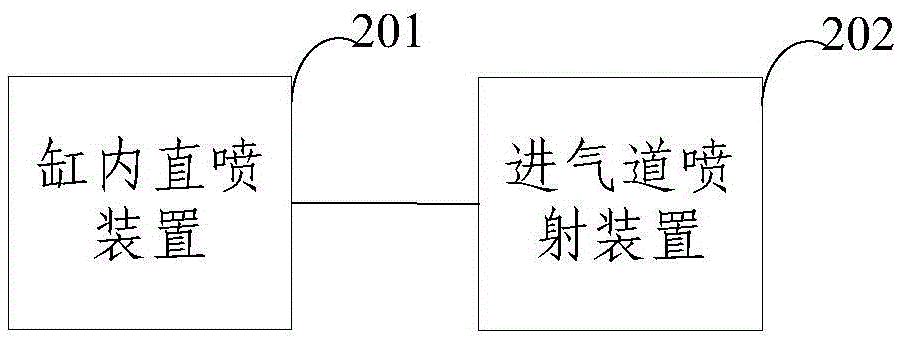

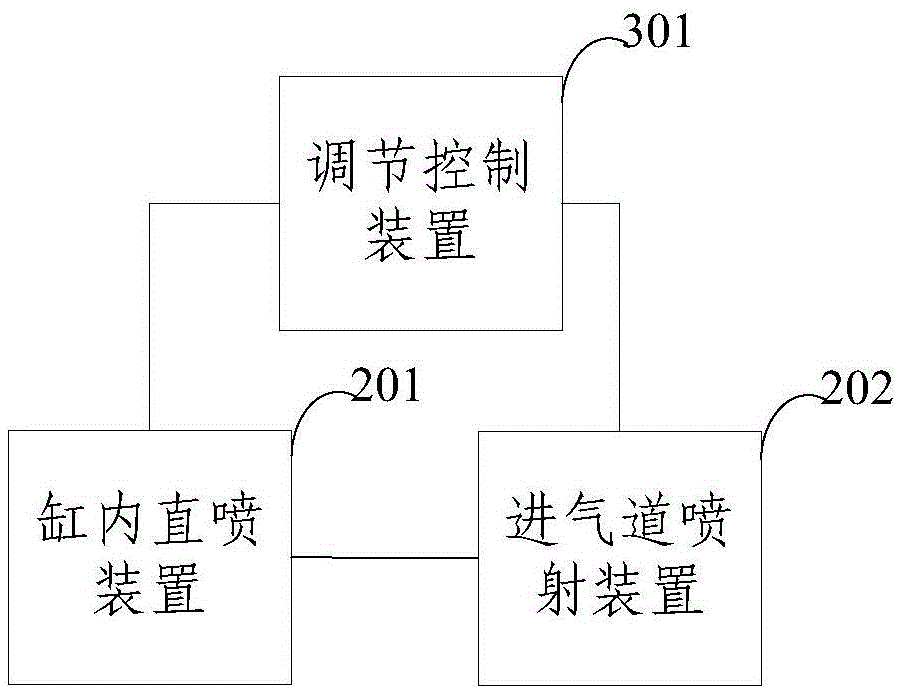

[0057] Step 401: Installing an intake port injection device 202 on a high compression ratio direct injection engine to inject high-octane fuel mixture.

[0058] In this embodiment 1, a high compression ratio (11-14) in-cylinder direct injection engine is used, the engine contains an in-cylinder direct injection device 201, and a set of intake air is installed on the intake port 1 of the engine. Road injection device 202, see Figure 5 . When the engine is running, the intake port 1 injection device 202 is used to inject a high-octane fuel mixture 2 in the intake port 1, including high-octane alternative fuels such as methanol, ethanol, and methane.

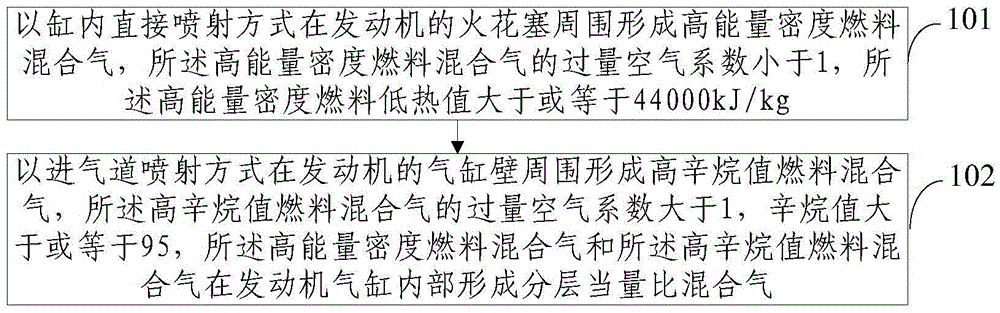

[0059] Step 402: Utilize the in-cylinder direct injection device to inject high energy density fuel mixture to form stratified equivale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com