Magnesium refining method and titanium sponge preparation method

A technology of sponge titanium and molten magnesium, which is applied in the fields of magnesium refining and sponge titanium preparation, can solve the problems of poor safety, affecting the quality of sponge titanium, and insufficient purity of magnesium raw materials, and achieves the effect of simple operation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a preparation method of titanium sponge, which comprises refining the molten magnesium raw material, and then contacting the refined molten magnesium raw material with titanium tetrachloride under the process conditions for producing sponge titanium by magnestic reduction, Wherein, the method of refining molten magnesium raw material is the refining method of magnesium raw material provided by the present invention.

[0025] The reaction conditions and production steps required for the preparation method of titanium sponge according to the present invention can adopt the conditions and steps for producing titanium sponge by magnesium thermal reduction known in the art. For example, the conditions of the reaction can include: relative to 1 ton of molten magnesium raw material, the feeding rate of titanium tetrachloride is 20-50 kilograms per hour, the consumption of titanium tetrachloride is 2.5-2.8 tons, and the temperature of the cont...

Embodiment 1-5

[0029] Examples 1-5 are used to illustrate the refining method of magnesium provided by the present invention.

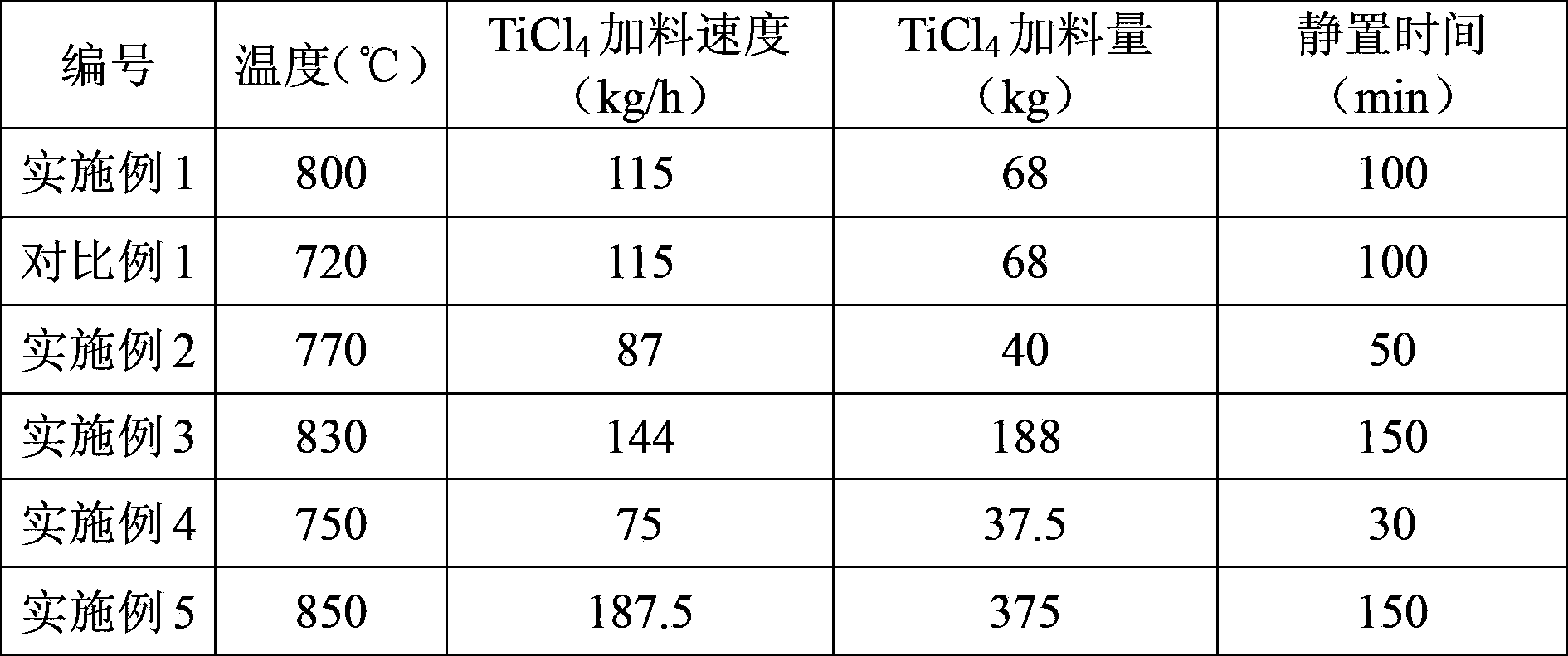

[0030] Table 1

[0031]

[0032] The magnesium raw materials are refined according to the conditions listed in Table 1. The specific refining steps are: under an argon atmosphere, 7.5 tons of magnesium raw materials are placed in the reduction device, and the magnesium-containing raw materials in the reduction device are removed by the temperature control system. Raise the temperature to the temperature required for contact, so that the magnesium raw material is in a molten state, and at different temperatures, add titanium tetrachloride to the reduction device, so that the titanium tetrachloride and the magnesium raw material are in contact. After the addition is completed, the magnesium The raw materials are left to stand for a period of time, so that the titanium sponge generated in the contacting process settles to the bottom of the reduction device, and the ...

Embodiment 6-11

[0039] Examples 6-11 are used to illustrate the preparation method of the titanium sponge provided by the present invention.

[0040] table 3

[0041] Numbering

temperature (°C)

TiCl 4 Feeding amount (t)

Example 6

800

20.932

Example 11

720

20.932

Example 7

770

20.960

Example 8

830

20.812

Example 9

750

20.963

Example 10

850

20.625

[0042] Prepare titanium sponge according to the conditions listed in Table 3 respectively, and the specific preparation steps are:

[0043] Utilize respectively the magnesium raw material 6 that obtains in embodiment 1-5 and comparative example 1 to carry out the preparation process of sponge titanium in the reducing device that carries out refining process after standing process finishes, under the same temperature and pressure condition, to reducing device Titanium tetrachloride was added at a rate of 230 kg per hour. Contact reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com