Preparation method of superhydrophobic nano thermal-insulation paint

A technology of nano heat insulation and heat insulation coating, applied in the direction of coating, can solve the problems of coating peeling, fluorine compound toxicity, expensive silane compound, etc., and achieve the effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

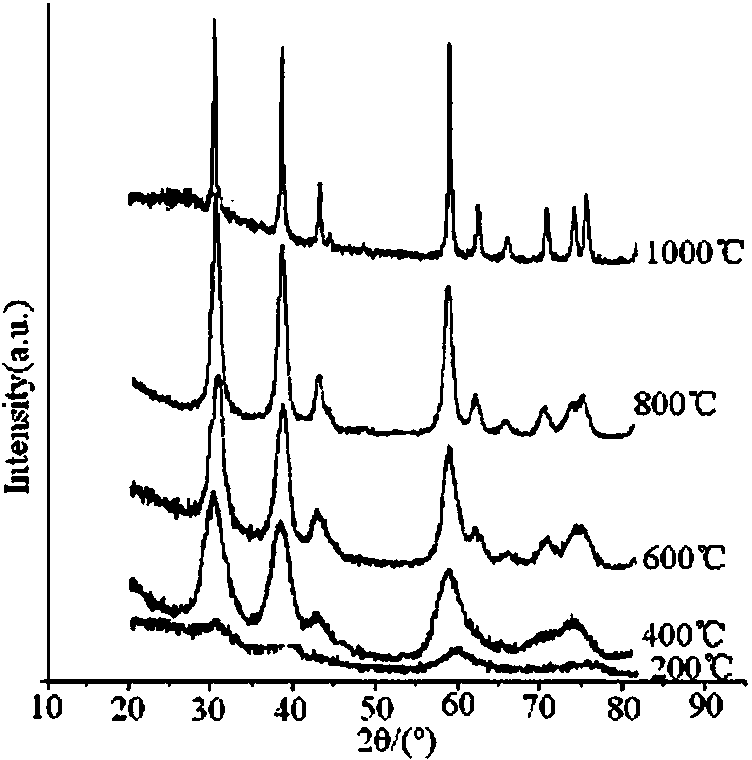

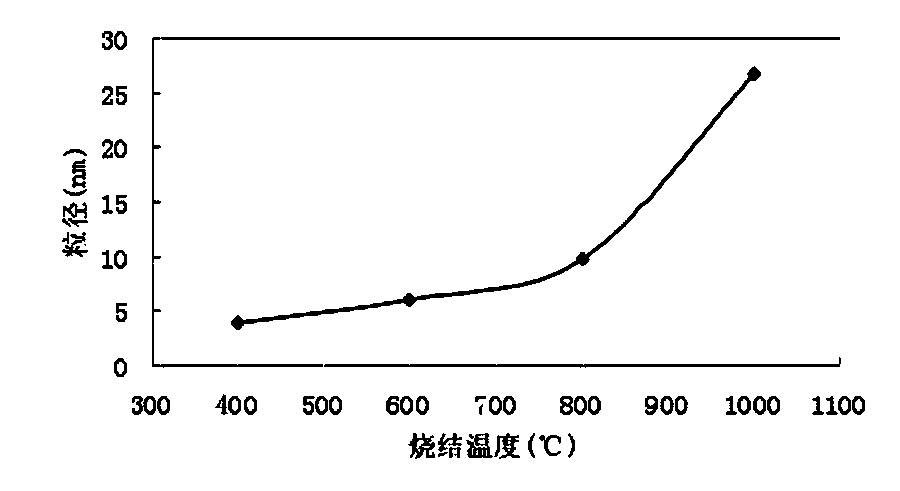

Image

Examples

Embodiment 1

[0027] A preparation method of superhydrophobic nano heat-insulating coating, comprising the following steps:

[0028] a). Prepare the base material:

[0029] Use 2-hydroxypropyl acrylate (HPA) as monomer, ethylene glycol dimethacrylate (EGD) as crosslinking agent, dibenzoyl peroxide (BPO) as initiator, and ethanol as solvent , configured as a monomer solution;

[0030] In the monomer solution, the concentration of 2-hydroxypropyl acrylate (HPA) is 0.32 mol / L; the concentration of ethylene glycol dimethacrylate (EGD) is 4.5 mmol / L; the diphenyl peroxide The concentration of formyl (BPO) was 5.2 mmol / L.

[0031] Add sodium dodecylbenzenesulfonate active agent and OP-10 emulsifier into ethanol, stir until the emulsifier is well dispersed to form an auxiliary agent solution. The concentration of the sodium dodecylbenzenesulfonate is 5.2 mmol / L, and the concentration of the OP-10 emulsifier is 6.2 mmol / L.

[0032] Gradually drop the monomer solution into the additive solution,...

Embodiment 2

[0045] 1. a preparation method of superhydrophobic nano heat-insulating coating, is characterized in that, may further comprise the steps:

[0046] a). Prepare the base material:

[0047] Use 2-hydroxypropyl acrylate (HPA) as monomer, ethylene glycol dimethacrylate (EGD) as crosslinking agent, dibenzoyl peroxide (BPO) as initiator, and ethanol as solvent , configured as a monomer solution;

[0048] In the monomer solution, the concentration of 2-hydroxypropyl acrylate (HPA) is 0.56mol / L; the concentration of ethylene glycol dimethacrylate (EGD) is 6.2mmol / L; the diphenyl peroxide The concentration of formyl (BPO) was 4.7 mmol / L.

[0049] Add sodium dodecylbenzenesulfonate active agent and OP-10 emulsifier into ethanol, stir until the emulsifier is well dispersed to form an auxiliary agent solution. The concentration of the sodium dodecylbenzenesulfonate is 7.5mmol / L, and the concentration of the OP-10 emulsifier is 9.7mmol / L.

[0050] Gradually drop the monomer solution in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com