Walling paint and preparation method thereof

A paint and wall technology, applied in the field of wall paint and preparation, can solve problems such as moldy spots on the wall, unfavorable human health, paint falling off, etc., achieve shortened pigment dispersion system, good environmental protection function, air Model plumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

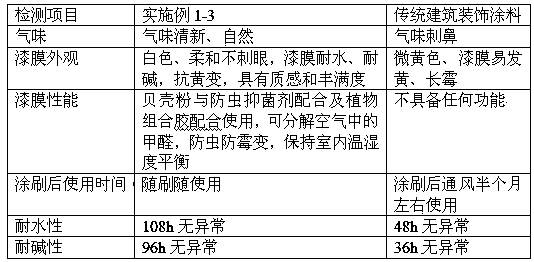

Embodiment 1

[0026] Add 250kg of water, 2.5kg of motherwortine, 2.05kg of D-504 wetting agent, 4.23kg of dispersant, and 3.02kg of defoamer into the reactor, and disperse for 30 minutes at a speed of 700-900 rpm; Then add 179.8kg of titanium dioxide, 43.2kg of talcum powder, and 91.01kg of shell powder, stir for 20-30 minutes at a speed of 500-1200 rpm, and sand-mill until the fineness of the material is below 50um; Then add 201.3kg of pure acrylic emulsion, 30.83kg of vegetable glue, 15.01kg of glycerin, 2.0kg of 95% ethanol, 1.98kg of defoamer, and 3kg of anti-insect and bacteriostatic agent to the reactor, and the Stir for 15-30 minutes under the same conditions; finally adjust the viscosity with 19.17kg of vegetable gum and 50kg of water, so that the viscosity at room temperature is (90-110) KU, and after passing through a 200-mesh sieve, it is a qualified product, which is packaged and stored .

[0027] Preparation of the vegetable gum composition: Weigh 41.3 kg of hollyhock vegetabl...

Embodiment 2

[0030]Add 260.5kg of water, 3kg of motherwortine, 3.15kg of D-504 wetting agent, 5.6kg of dispersant, and 3.8kg of defoamer into the reactor, and disperse for 30 minutes at a speed of 700-900 rpm; Then add 230.4kg of titanium dioxide, 50.6kg of talcum powder, and 162kg of shell powder, stir for 20-30 minutes at a speed of 500-1200 rpm, and sand-mill until the fineness of the material is below 50um; Add 243.7kg of pure acrylic emulsion, 40kg of vegetable gum, 31.6kg of glycerin, 3.58kg of 95% ethanol, 1.1kg of defoamer, and 5kg of anti-insect and bacteriostatic agent into the reactor, at a speed of 400-800 rpm Stir for 15-30 minutes; finally use 20kg of vegetable gum and 29.5kg of water to adjust the viscosity so that the viscosity at room temperature is (90-110) KU, and after passing through a 200-mesh sieve, it is a qualified product and packaged for storage.

[0031] Preparation of the vegetable gum composition: Weigh 50 kg of hollyhock vegetable gum and 10 kg of rosin ester...

Embodiment 3

[0034] Add 250kg of water, 3kg of motherwort, 3kg of D-504 wetting agent, 4.5kg of dispersant, and 3.8kg of defoamer into the reactor, and disperse for 30 minutes at a speed of 700-900 rpm; then add 200kg of titanium dioxide, 55kg of talcum powder, and 135kg of shell powder are stirred for 20-30 minutes at a speed of 500-1200 rpm, and sand-milled until the fineness of the material is below 50um; then add 225kg of pure Acrylic emulsion, 35kg vegetable glue, 25kg glycerin, 3kg95% ethanol, 0.7kg defoamer, 4kg insect-proof and bacteriostatic agent are put into the reaction kettle, and stirred for 15-30 minutes under the condition of rotating speed of 400-800 rpm; finally Use 10kg of vegetable glue and 30kg of water to adjust the viscosity so that the viscosity at room temperature is (90-110) KU. After passing through a 200-mesh sieve, it is a qualified product, which is packaged and stored.

[0035] Preparation of vegetable gum composition: Weigh 37.5 kg of yellow hollyhock vegeta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com