Neutral deinking agent and preparation method thereof

A technology of neutral deinking agent and surfactant, which is applied in the field of neutral deinking agent and its preparation, can solve problems such as ink residue, reduce production costs, reduce environmental and human hazards, and overcome the partial deinking efficiency. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

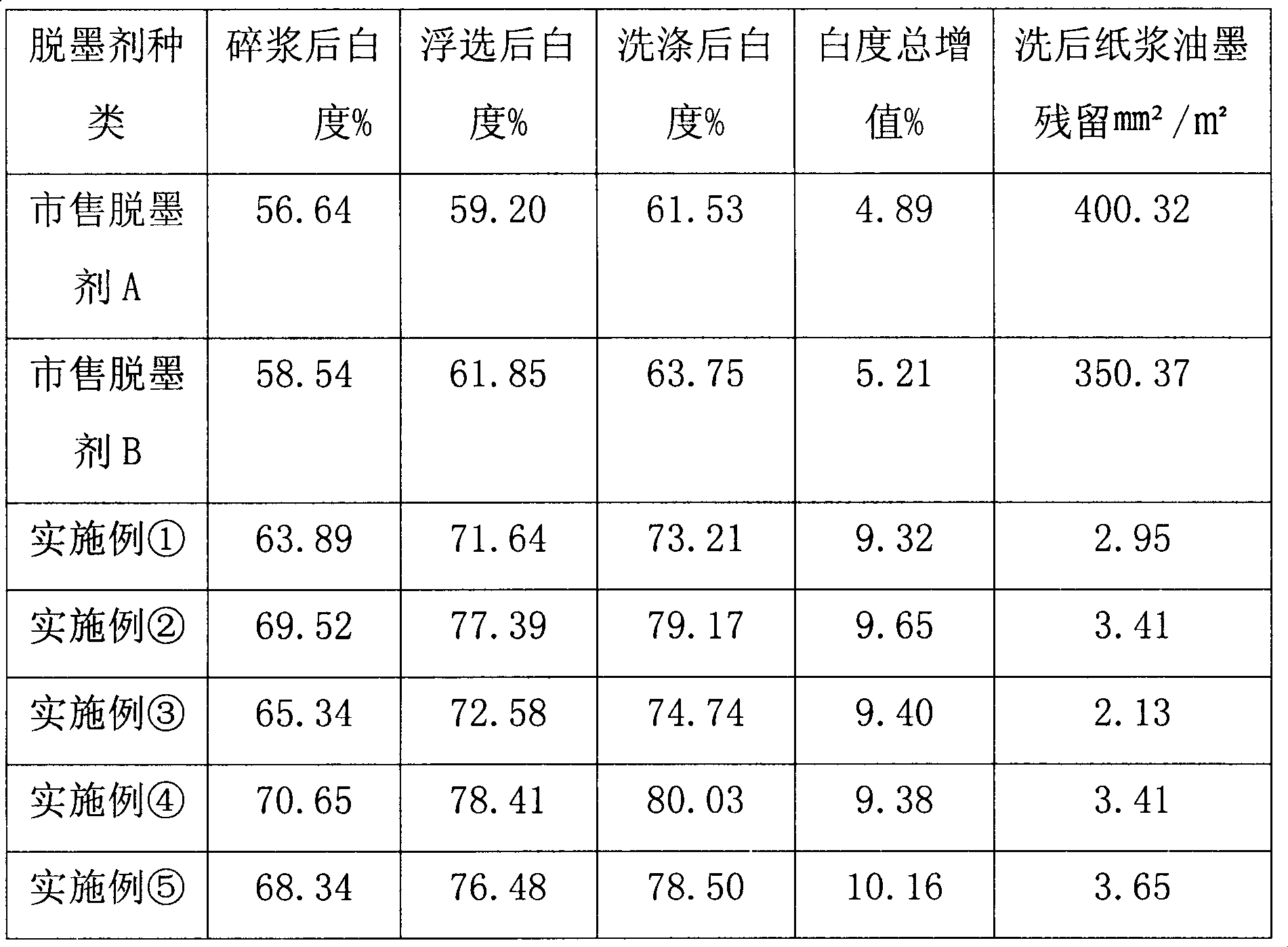

Examples

Embodiment 1

[0030] ① Add 20 parts of water to the reaction kettle, then add 1 part of inorganic mineral soil while stirring, the stirring speed is 100r / min, and the adding time is 10 minutes. After adding, continue stirring for 20 minutes; , add 10 parts of sodium maleic abietate and 1 part of sodium lignosulfonate successively under stirring, and continue stirring for 10 minutes after adding; ③ Add 10 parts of lauryl sulfate, polyoxyethylene alkyl ether 10 parts, 10 parts of fatty acid salt, 1 part of inorganic salt, continue to stir for 15 minutes after adding; ④ Add water to adjust the concentration to 58%, stop stirring, naturally cool to below 40°C, and then pack.

Embodiment 2

[0032] ① Add 25 parts of water to the reaction kettle, then add 2 parts of inorganic mineral soil while stirring, the stirring speed is 150r / min, and the adding time is 10 minutes. After adding, continue stirring for 20 minutes; , add 12 parts of sodium rosin succinate sulfonate and 2 parts of sodium lignosulfonate successively under stirring, and continue stirring for 10 minutes after adding; ③Add 13 parts of lauryl sulfate, polyoxyethylene alkane 13 parts of base ether, 12 parts of fatty acid salt, and 1 part of inorganic salt, and continue to stir for 15 minutes after adding; ④ Add water to adjust the concentration to 59%, stop stirring, naturally cool to below 40°C, and then pack.

Embodiment 3

[0034] ① Add 30 parts of water to the reaction kettle, then add 3 parts of inorganic mineral soil while stirring, the stirring speed is 200r / min, and the adding time is 20 minutes. After adding, continue stirring for 20 minutes; , add 15 parts of rosin amine polyoxyethylene ether and 3 parts of sodium lignosulfonate successively under stirring, and continue stirring for 25 minutes after adding; ③ add 15 parts of dodecyl sulfate, polyoxyethylene alkyl Add 15 parts of ether, 13 parts of fatty acid salt, and 1.5 parts of inorganic salt, and continue to stir for 15 minutes after adding; ④ Add water to adjust the concentration to 60%, stop stirring, naturally cool to below 40°C, and then pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com