Waste rubber powder modified asphalt and preparation method thereof

A technology of waste rubber powder and modified asphalt, applied in building components, building insulation materials, construction and other directions, can solve the problems of complex rubber modified asphalt process, increase environmental pollution and high production cost, save production equipment and reduce production. The effect of high process and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

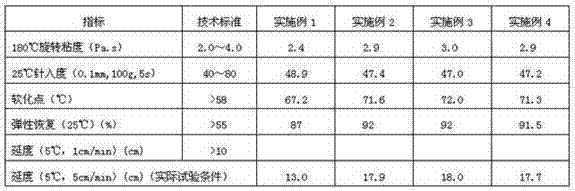

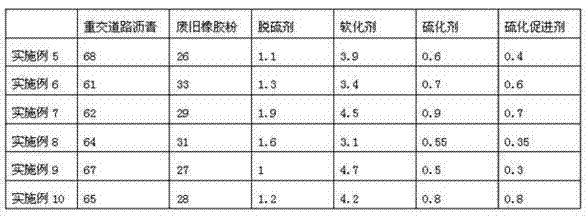

Embodiment 1

[0023] A waste rubber powder modified asphalt, the raw materials are composed of the following materials according to the weight ratio: 68% of asphalt, 25% of waste rubber powder, 2% of desulfurizing agent, 3.5% of softening agent, 1% of vulcanizing agent, and 0.5% of vulcanization accelerator.

[0024] The desulfurizing agent is diphenyl disulfide, the softening agent is C9 petroleum resin, the vulcanizing agent is sulfur, and the vulcanization accelerator is a dithiocarbamate vulcanization accelerator; the rubber powder is crushed rubber powder from waste tires, fine The degree is 20-40 mesh; the asphalt is heavy traffic road asphalt.

[0025] The preparation method comprises the following steps:

[0026] (1) Put 68Kg of heavy-duty road asphalt into the reaction kettle, and when heated to 160-180°C, put in 25Kg of waste rubber powder, 2Kg of desulfurizer, and 3.5Kg of softener, stir to mix the above materials evenly, and raise the temperature by 10-30°C;

[0027] (2) Cut th...

Embodiment 2

[0029] A waste rubber powder modified asphalt, the raw material is composed of the following materials according to weight ratio: 62.5% of asphalt, 30% of waste rubber powder, 2% of desulfurizing agent, 4% of softening agent, 1% of vulcanizing agent, and 0.5% of vulcanization accelerator.

[0030] The desulfurizing agent is diphenyl disulfide, the softening agent is C9 petroleum resin, the vulcanizing agent is sulfur, and the vulcanization accelerator is a dithiocarbamate vulcanization accelerator; the rubber powder is crushed rubber powder from waste tires, fine The degree is 20-40 mesh; the asphalt is heavy traffic road asphalt.

[0031] The preparation method comprises the following steps:

[0032] (1) Put 62.5Kg of heavy traffic road asphalt into the reaction kettle, when heated to 160-180°C, put in 30Kg of waste rubber powder, 2Kg of desulfurizer, 4Kg of softener, stir to mix the above materials evenly, and raise the temperature by 10-30°C;

[0033] (2) Use a high-speed ...

Embodiment 3

[0035] A kind of asphalt modified by waste rubber powder, the raw materials are composed of the following materials according to the weight ratio: 60% of asphalt, 35% of waste rubber powder, 1% of desulfurizing agent, 3% of softening agent, 0.5% of vulcanizing agent, and 0.5% of vulcanization accelerator.

[0036] The desulfurizing agent is diphenyl disulfide, the softening agent is C9 petroleum resin, the vulcanizing agent is sulfur, and the vulcanization accelerator is a dithiocarbamate vulcanization accelerator; the rubber powder is crushed rubber powder from waste tires, fine The degree is 20-40 mesh; the asphalt is heavy traffic road asphalt.

[0037] The preparation method comprises the following steps:

[0038] (1) Put 60Kg of heavy traffic road asphalt into the reaction kettle, and when heated to 160-180°C, put in 35Kg of waste rubber powder, 1Kg of desulfurizer, and 3Kg of softener, stir to mix the above materials evenly, and raise the temperature by 10-30°C;

[0039] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com