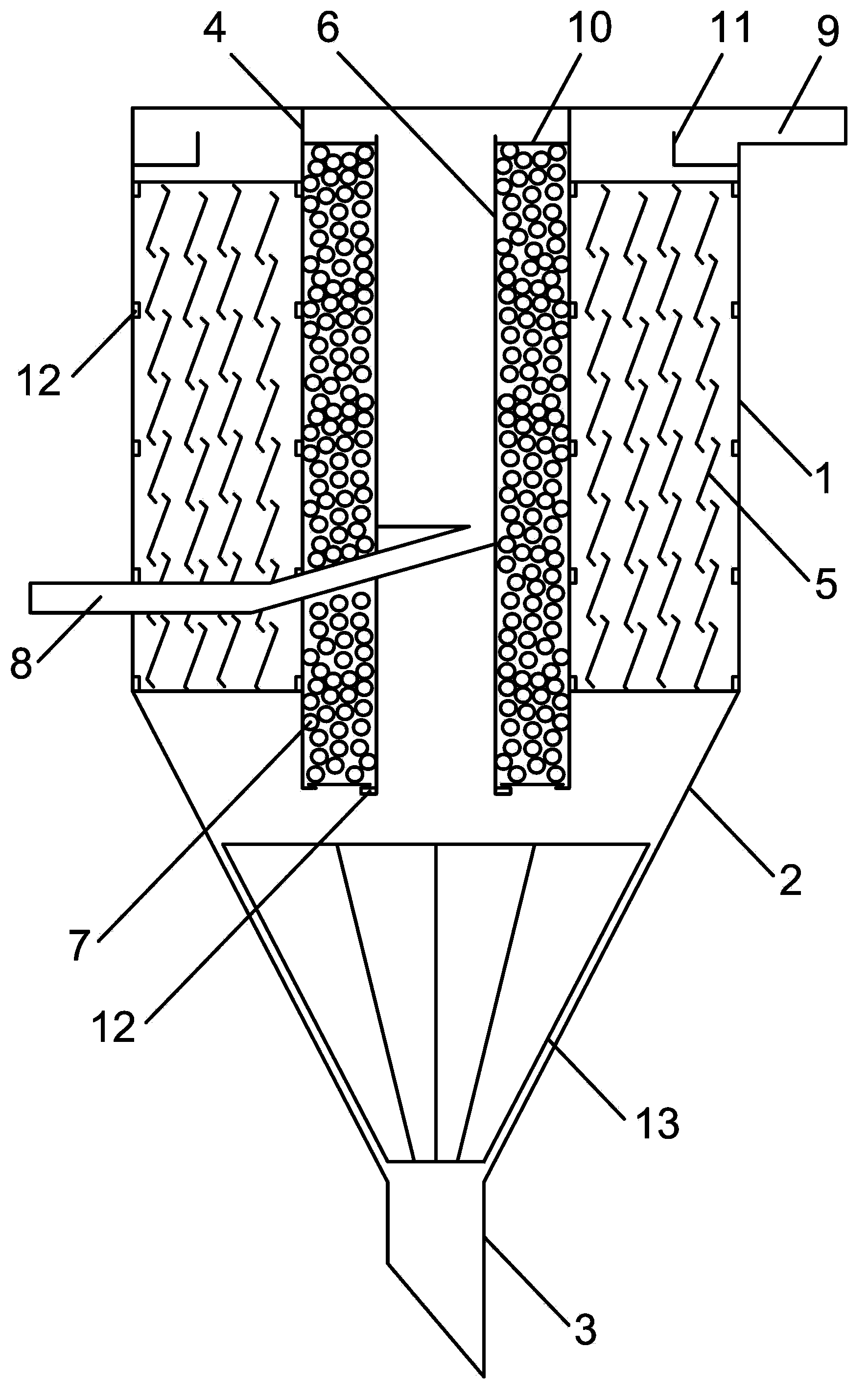

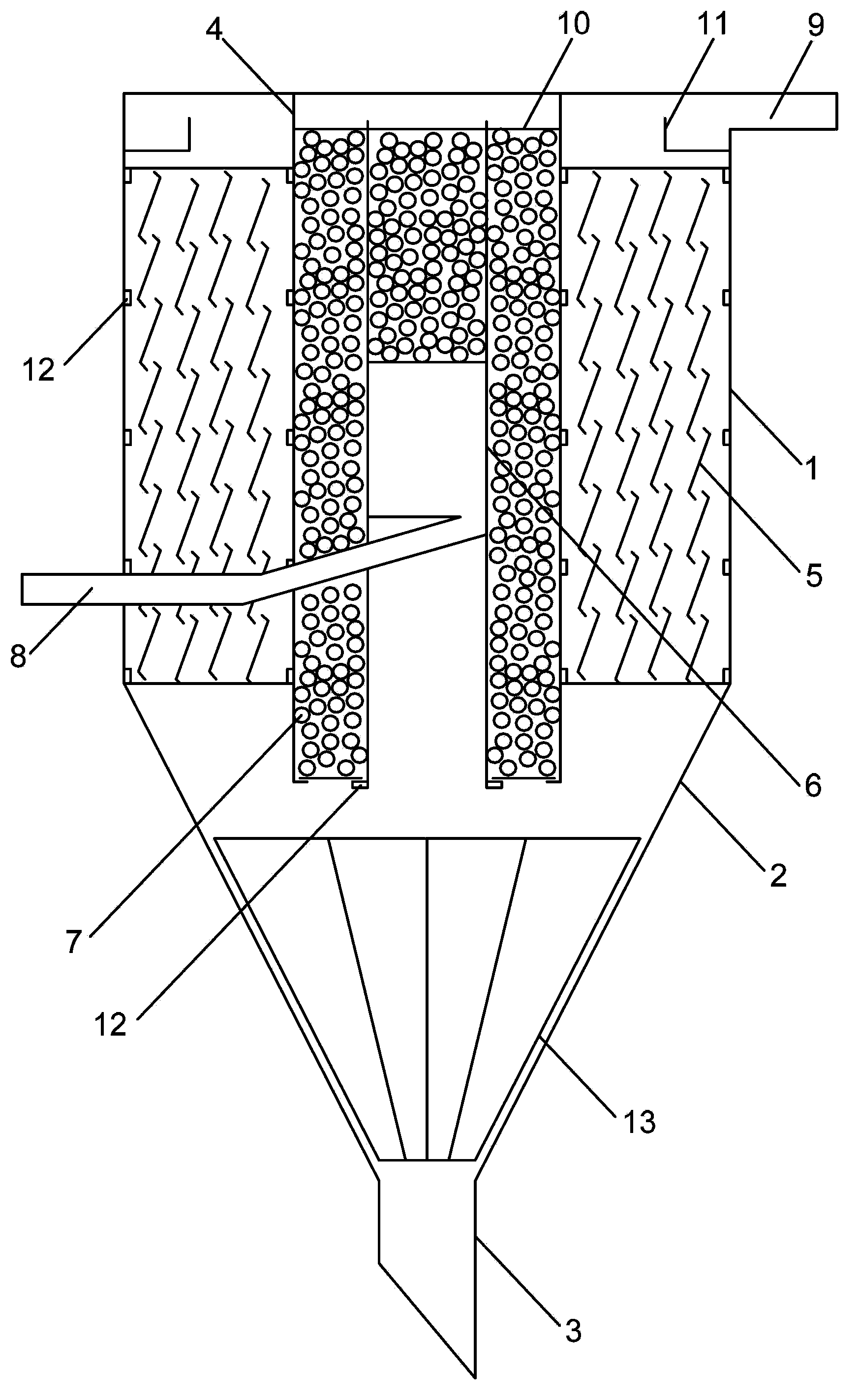

Micro-vortex high-efficiency clarification reactor and operation method for same

A reactor and vortex technology, which is applied in the field of micro-vortex high-efficiency clarification reactors, can solve the problems of difficult installation of equipment, low work efficiency, and short service life, and achieve saving of chemical consumption, high work efficiency, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Example 1: The sewage of a mine water plant, the influent water quality is: suspended matter is 200~1500mg / L, turbidity is 30~150NTU, after being treated by the micro-vortex high-efficiency clarification reactor of the present invention, the suspended matter≤ 20mg / L, turbidity≤3.5NTU.

Embodiment 2

[0080] Example 2: For sewage from a gas-making workshop, the influent suspended matter content is about 100-500 mg / L. After being treated by the micro-vortex high-efficiency clarification reactor of the present invention, the effluent suspended matter content is ≤15 mg / L.

Embodiment 3

[0081] Example 3: For sewage from a coal chemical plant, the influent suspended solids content is about 50-300 mg / L. After being treated by the micro-vortex high-efficiency clarification reactor of the present invention, the effluent suspended solids content is ≤20 mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com