Compression conveying mechanism for bagged spring production

A conveying mechanism and pocket spring technology, applied in conveyors, mechanical conveyors, packaging, etc., can solve the problems of bulky, low efficiency, unstable conveying, etc., and achieve high automation, stable compression conveying, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

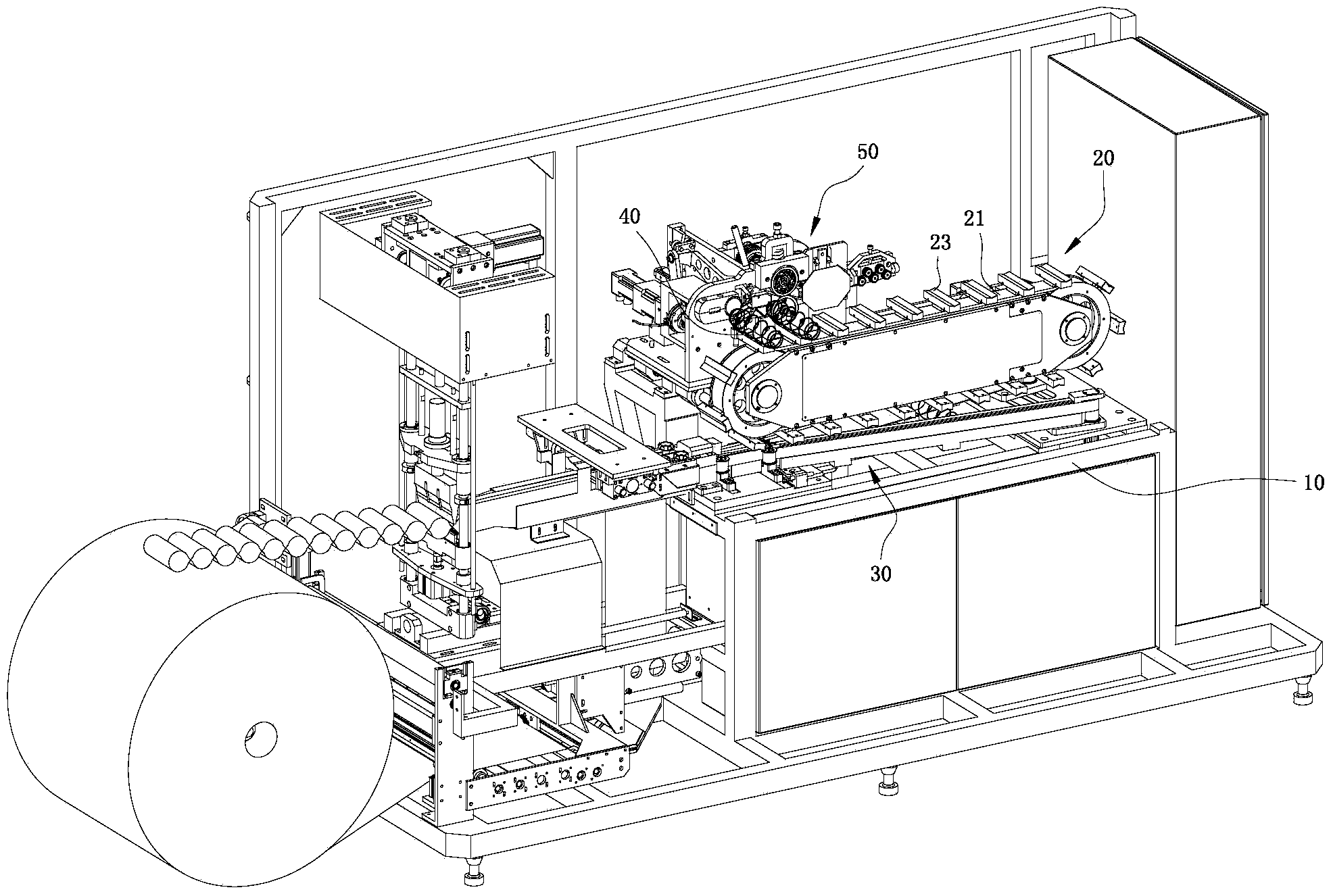

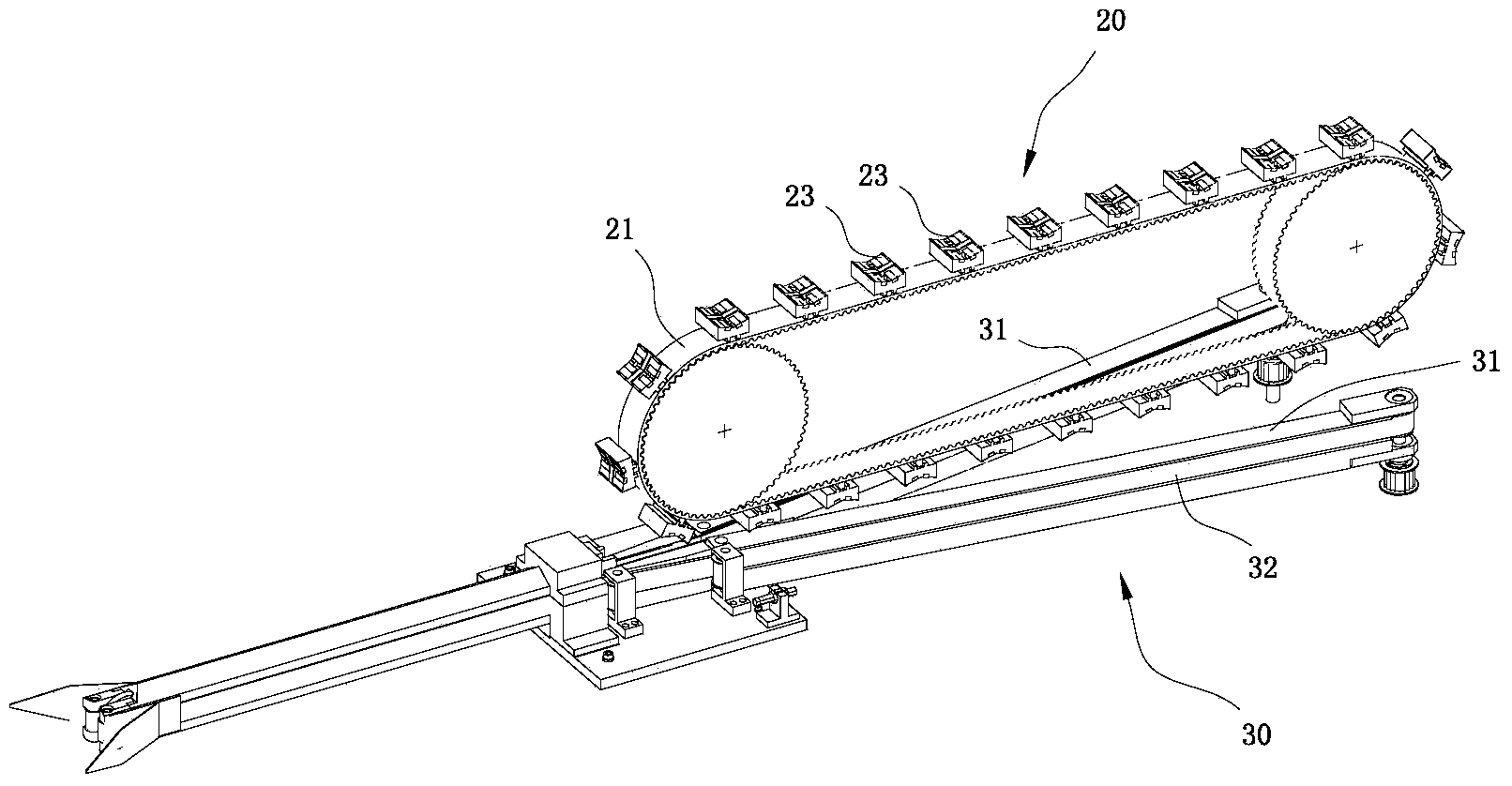

[0012] refer to figure 1 with figure 2 , a pocket spring production compression delivery mechanism, including a frame 10, a spring delivery mechanism 20, a spring compression delivery mechanism 30, the spring compression delivery mechanism 30 receives and compresses the spring 40 delivered by the spring delivery mechanism 20, and the spring compression delivery mechanism 30 includes two pairs of baffle plates 31 arranged on the frame 10 and a conveyor belt 32 wound around the outside of the baffle plates 31, the distance between the two baffle plates 31 gradually decreases from one end to the other, and the spring conveying mechanism 20 conveys the spring 40 to between the two baffle plates 31 and drive the spring 40 to move to make the spring 40 move from the larger end of the distance between the two baffle plates 31 to the other end where the distance between the two baffle plates 31 is smaller. The spring 40 is gradually compressed as the distance between them gradually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com