Straw briquetting mechanism with vertical shaft, flat die and straight roller

A flat die, straight roll technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problem of late start and other problems, and achieve the effect of not easy to block, good work continuity, and regular shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below with reference to the drawings and embodiments.

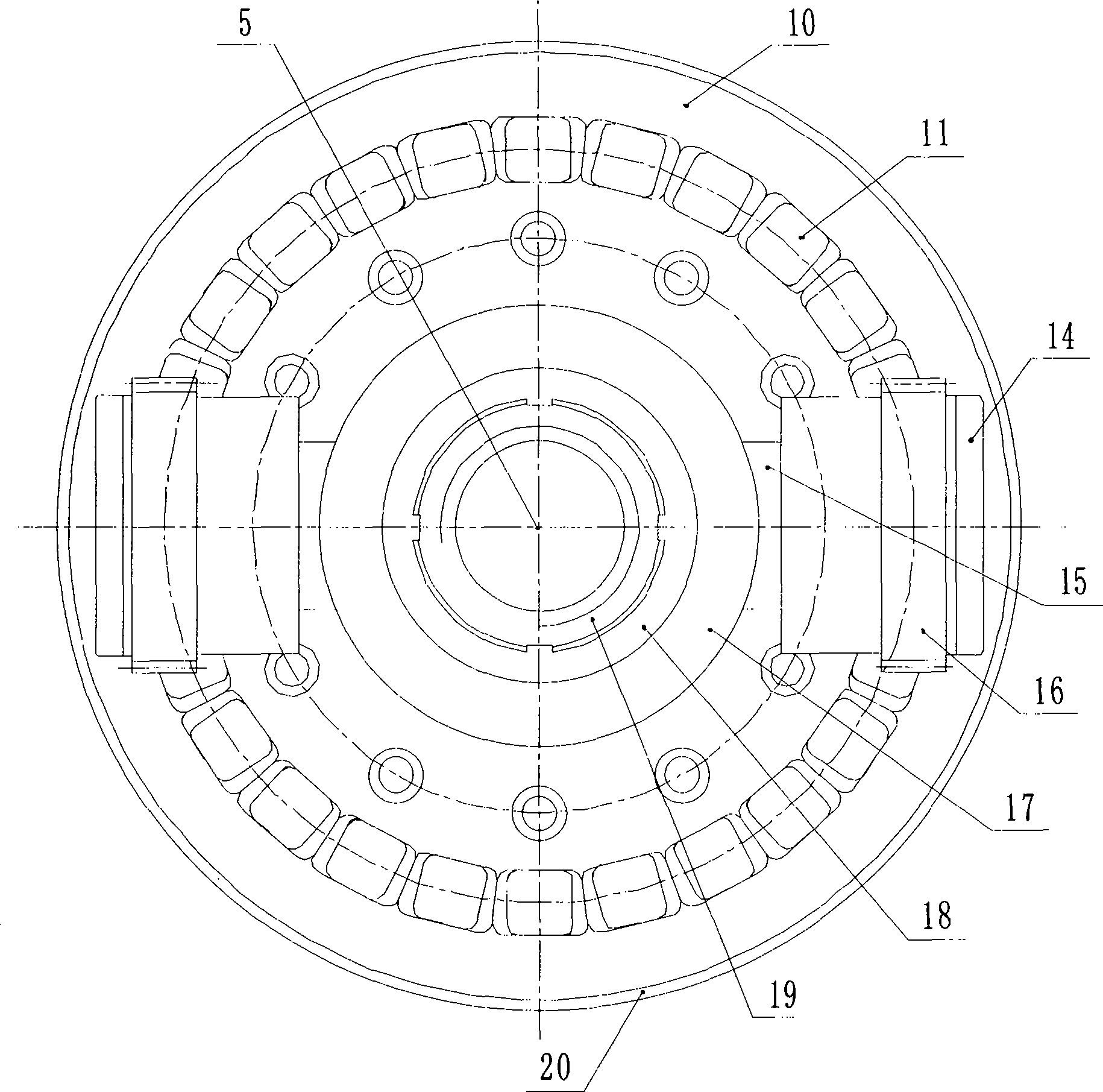

[0011] It can be seen from the figure that the main shaft 5 is vertically arranged in the middle of the base 3 and the support 7. The upper end thrust centripetal symmetrical spherical roller bearing 9 is fixed to the lower end tapered roller bearing 2, and the bottom is sealed and limited by the bearing end cover 1. , The base 3 and the support 7 are connected by bolts 6. The flat mold 10 is horizontally fixed on the support 7 by countersunk screws 12, and the collecting hopper 8 is also connected to the support 7, corresponding to the lower outlet of the die hole 11. A plurality of die holes 11 are evenly distributed in the circumference of the flat mold 10 . The pressure roller frame sleeve 17 is installed on the main shaft 5 in the form of a spline, and is seated on the support 7 through a washer 13, and the top end is fixed by a round nut 19 through a pressure cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com