A special automatic oil injection device for aerated concrete block mold

A kind of technology of air-entrained concrete and oil spraying device, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of increased labor costs, uneven oiling, slow operation speed, etc., to improve spraying efficiency, improve spraying effect, improve The effect of using the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

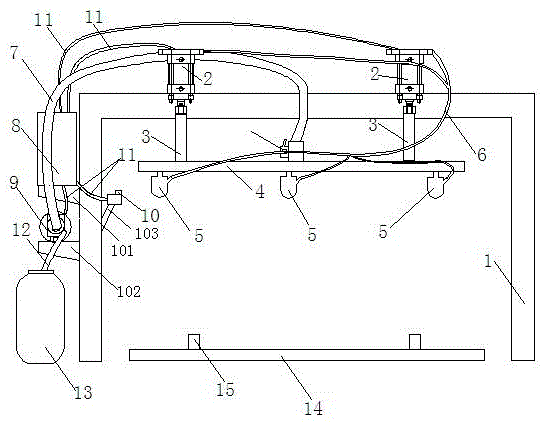

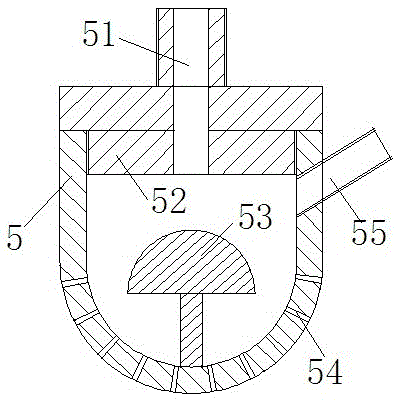

[0025] As shown in the figure, a special automatic oil spraying device for aerated concrete block molds includes a frame 1, wherein the frame 1 is in the shape of an "n" and is arranged above the delivery production line 14 of the mold 17. The frame There are two cylinders 2 on the top of 1, and the cylinders 2 are fixedly connected to the frame 1 by bolts; the bottoms of the two cylinders 2 are vertically connected with support arms 3; the support arms 3 are horizontally connected with an oil pipe 4. The oil pipe is located below the support arm 3; the bottom of the oil pipe is provided with three spherical nozzles 5, the top of the spherical nozzle 5 is square, the bottom is hemispherical, and the center of the top is provided with an oil inlet 51. The oil inlet The outside of the bottom of 51 is provided with a positioning and fixing block 52. An oil separator 53 is arranged below the oil inlet hole 51. The oil separator 53 is umbrella-shaped. The upper end of the oil separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com