A paint automatic spraying machine

An automatic spraying and coating technology, which is applied in the direction of spraying devices, buildings, building structures, etc., can solve the problems of unstable coating quality, high labor intensity, poor coating quality, etc., so as to improve the uniformity of spraying and improve the efficiency of spraying , spraying quality good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

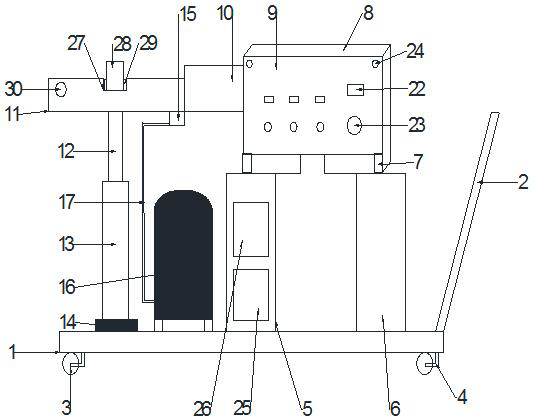

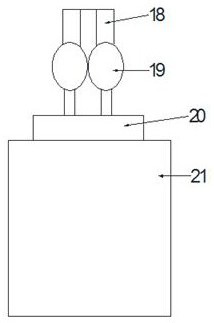

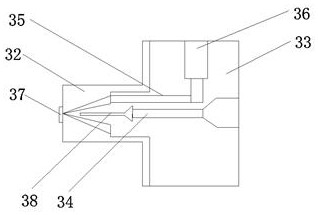

Embodiment 1

[0027] see Figure 1-4 , the present invention provides a technical solution: an automatic paint spraying machine, including a base 1, a handrail 2 is provided on one side of the base 1, a wheel 3 is provided at the bottom of the base 1, and a wheel clamp is connected to the wheel 3 4. A control box 5 and a nitrogen source device 6 are arranged on the right side above the base 1, and a connecting column 7 is respectively arranged above the control box 5 and the nitrogen source device 6, and a double body is arranged above the connecting column 7. The nitrogen machine 8 is fixedly connected with the connecting column 7, and the front of the two-body nitrogen machine 8 is provided with a console 9, and the left side of the two-body nitrogen machine 8 is connected with an automatic spraying device 10 and a spray gun holder 11 successively, and the A support column 12 is provided below the spray gun holder 11, the support column 12 links to each other with a lifting cylinder 13, a...

Embodiment 2

[0033] In this embodiment, an automatic paint spraying machine includes a base 1, a handrail 2 is provided on one side of the base 1, a wheel 3 is provided at the bottom of the base 1, and a wheel clamp 4 is connected to the wheel 3. A control box 5 and a nitrogen source device 6 are arranged on the right side above the base 1, and a connecting column 7 is respectively arranged above the control box 5 and the nitrogen source device 6, and a double-body nitrogen machine 8 is arranged above the connecting column 7 and Fixedly connected with the connecting column 7, the double-body nitrogen machine 8 is provided with a console 9 on the front, and the left side of the double-body nitrogen machine 8 is sequentially connected with an automatic spraying device 10 and a spray gun holder 11, and the spray gun holder 11 A support column 12 is provided below, and the support column 12 is connected with the lifting cylinder 13. A moving seat 14 is provided between the lifting cylinder 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com