Device for making multi-level saturation fuzzy gradient cosmetic powder

A production device and fuzzy technology, applied in the field of machinery, can solve the problems of poor strain capacity and low production capacity, and achieve the effect of improving work efficiency and uniform distribution of powder particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

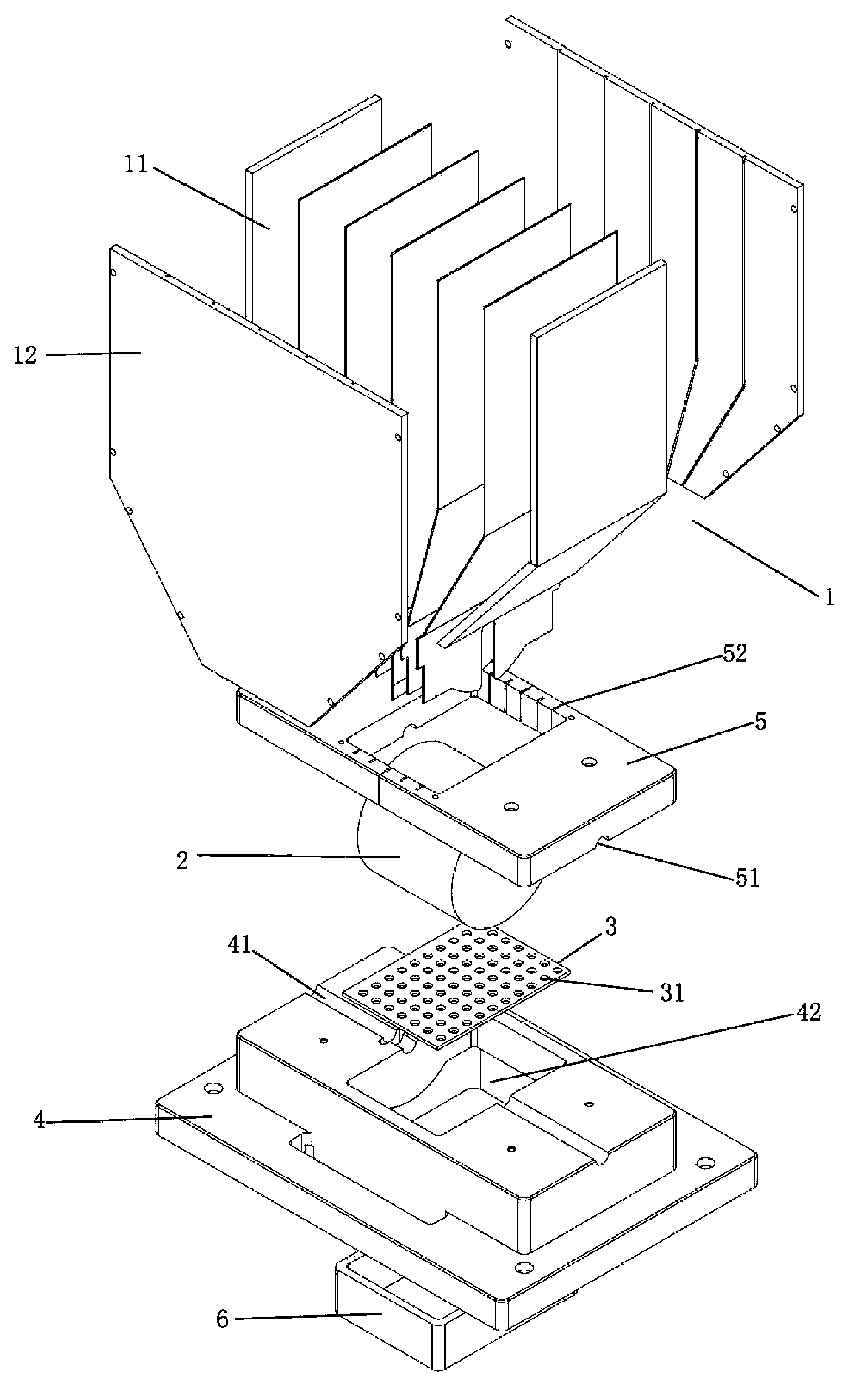

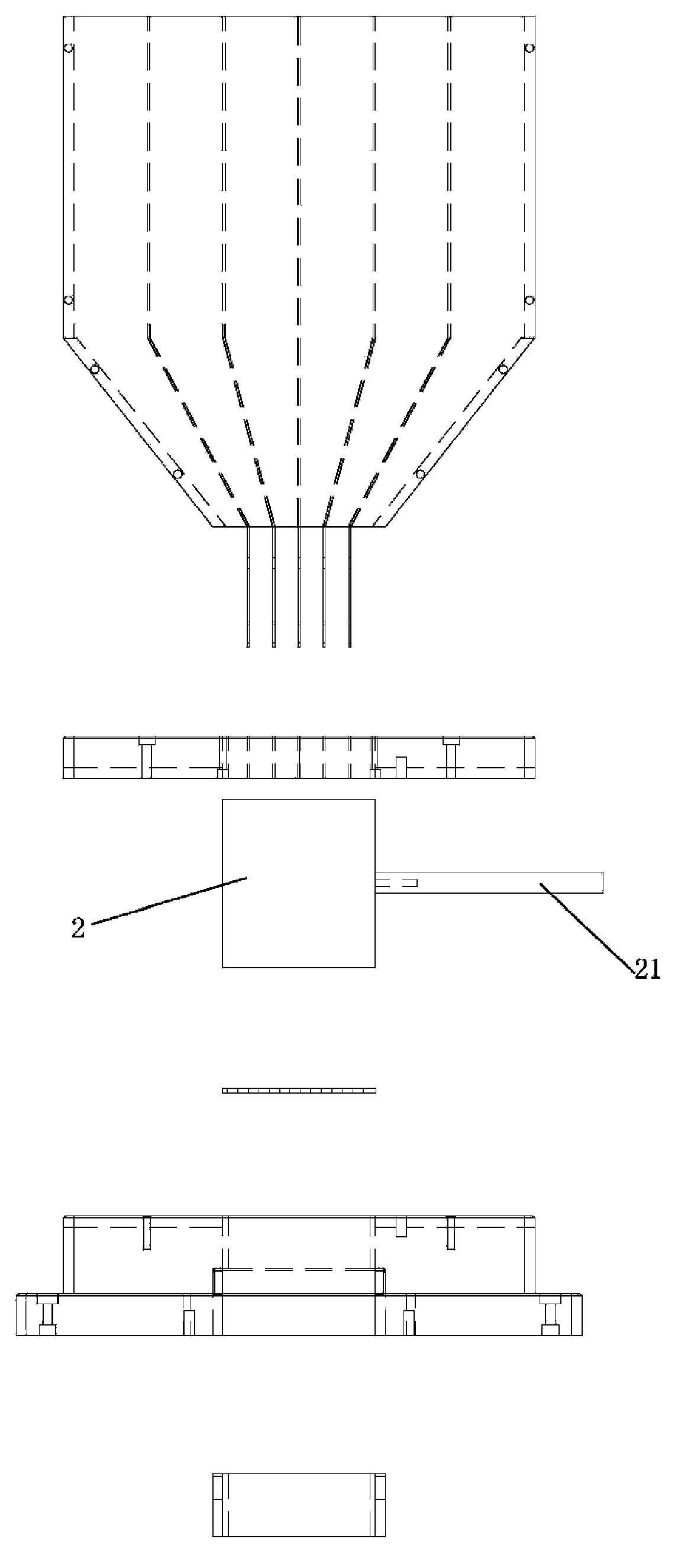

[0016] like figure 1 and figure 2 As shown, a multi-grading fuzzy gradient make-up powder manufacturing device of the present invention includes a barrel 1, a stirring brush 2, a screen 3 and a barrel base 4, and the lower end of the barrel 1 is fixed on the On the above-mentioned barrel base 4, the upper end of the barrel 1 is provided with a feed port, and the lower end is provided with a discharge port, and the stirring brush 2 and the sieve are arranged between the discharge port and the barrel base. Net 3, the barrel 1 is provided with at least two color powder cavities through the partition plate 11, the screen 3 is provided with a plurality of holes 31, and the stirring brush 2 rotates around its shaft 21 Rotate, the sieve 3 is in contact with the stirring brush 2.

[0017] Further, the outer contour of the stirring brush 2 is cylindrical, and the stirring brush 2 is set on the barrel base 4 through its rotating shaft 21, and the barrel base 4 is provided with half ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com