Secondary wire wiring method for high-voltage/low-voltage switch cabinet

A technology of high and low voltage switches and wiring methods, which is applied in the direction of switchgear, electrical components, etc., and can solve problems such as electrical wires that cannot be ignored, disordered, broken, and short-circuited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A method for wiring secondary lines of high and low voltage switch cabinets, comprising the following steps:

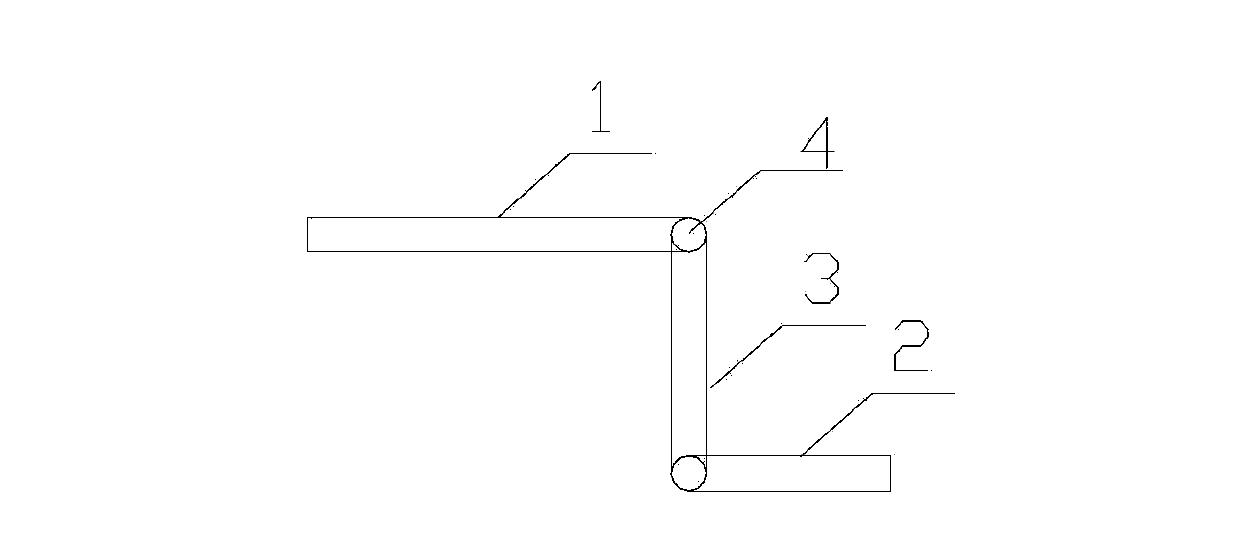

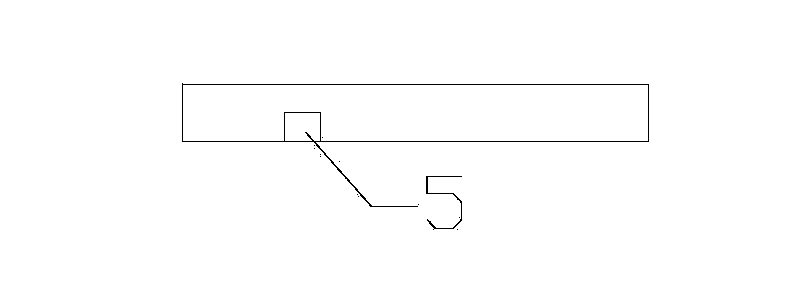

[0013] ① Determine the direction of the wire harness according to the installation position of the components in the switch cabinet, and at the same time, make the tooling frame according to the direction of the wire harness. Such as figure 1 As shown: the tooling frame is composed of three grooved plates in a "Z" shape, wherein the bottom plate 1 and the top plate 2 are parallel, and the bottom plate and the top plate are vertically connected to the connecting plate 3 through the shaft 4, and the three grooved plates have outlets 5.

[0014] ② Separate the primary line and secondary line, strong current and weak current wires in the switch cabinet, and go to one side;

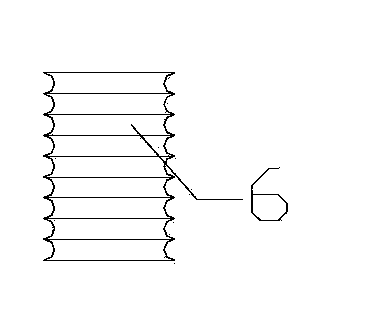

[0015] ③ The grooved plates in the tooling frame for the door line should be connected by a retractable port 6 (such as image 3 shown);

[0016] ④ There are outlets for the tooling racks us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com