Terminal for partial discharge tests on crosslinked polyethylene power cable of 10 kV or lower

A cross-linked polyethylene, power cable technology, applied in the direction of testing dielectric strength, etc., can solve the problems of long stripping distance at both ends of the cable, discharge or signal attenuation, poor stability of oil terminals, etc., to improve the test stability, shorten the The effect of stripping and cutting length and shortening installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

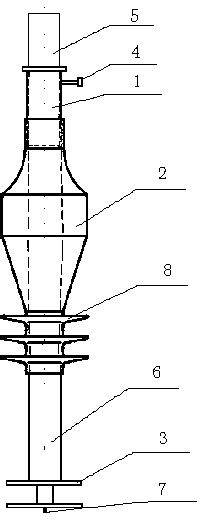

[0019] see figure 1 , the invention discloses a 10kV and below cross-linked polyethylene power cable partial discharge test terminal. As shown in the figure: it includes a stress ring 1, a pressure equalizing sleeve 2, and a high voltage connection pressure equalizing ring 3. The stress ring 1 has a screw 4 that can fix it on the cable shielding layer 5; the stress ring 1 is set at the interface between cable shielding and insulation, and the pressure equalizing sleeve 2 is set on the cable insulated core 6, the semi-conductive interface of the pressure equalizing sleeve 2 is connected to the lower end of the stress ring 1, and the pressure equalizing sleeve 2 has 2- 4 umbrella skirts 8; the high-voltage connection pressure equalizing ring 3 is located below the pressure equalizing sleeve 2, the upper end of the high-voltage connection pressure equalizing ring 3 is connected to the core conductor of the cable insulation core 6, and the lower end of the high-voltage connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com