A particle size distribution measurement method based on shifrin transformation

A technology of particle size distribution and measurement method, applied in measurement devices, particle size analysis, particle and sedimentation analysis, etc., can solve problems such as inability to adapt to various situations and indistinguishable, and achieve the best inversion effect and good noise effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

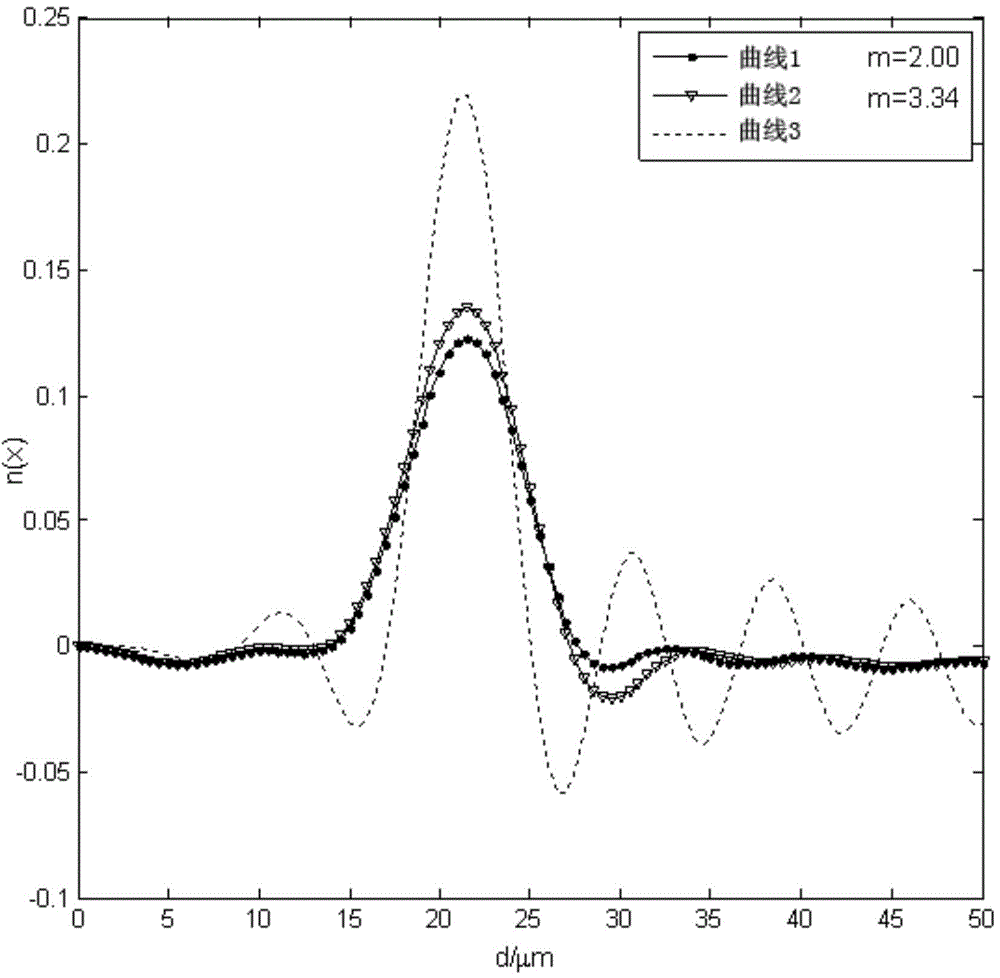

Embodiment 1

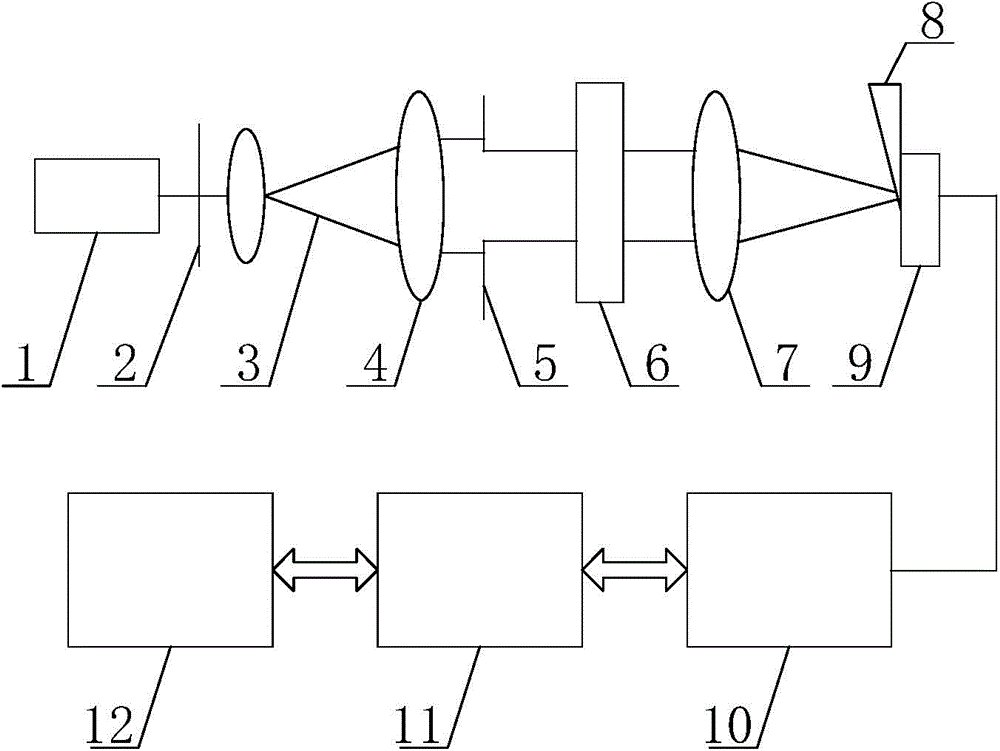

[0033] The present embodiment is based on the particle size distribution measurement method of shifrin transformation, and the steps are as follows:

[0034] Step 1. Set the suspension of standard particle latex balls (produced by Beijing Institute of Chemical Industry and Metallurgy) in the sample box, specifically, suspend the sample of GBW(E)120006 (nominal mass peak particle size 20.46±0.4um) in pure water A unimodal distribution particle group is made in the sample box, and the sample box containing the aforementioned sample to be tested is installed in place;

[0035] Step 2. Turn on the laser. The light emitted by the laser becomes parallel light after attenuation, filtering, beam expansion and collimation, and then the light beam with a moderate diameter is adjusted by the iris to enter the sample box, and a beam will be formed on the focal plane of the objective lens. The scattering spectrum of the particle population;

[0036] Step 3, adjust the attenuator, so that ...

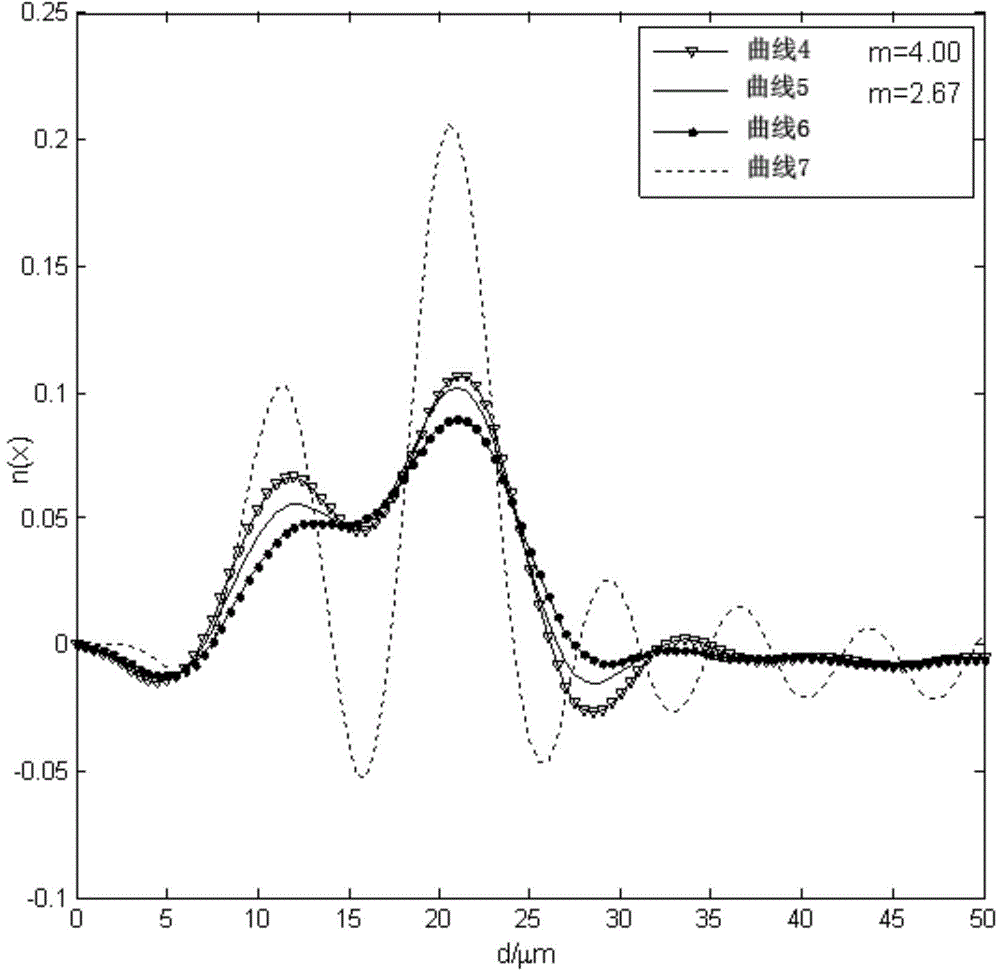

Embodiment 2

[0045] The steps of this embodiment can refer to the steps of Embodiment 1. The difference is: 1. The measurement object is a particle sample with bimodal distribution, specifically GBW (E) 120006 (nominal mass peak particle diameter 20.46 ± 0.4um) and GBW(E)120024 (nominal mass peak particle size 10.90±0.2um) is mixed to form a bimodal distribution particle group; 2. In step 6, if there is no clear distinction between adjacent distribution peaks after comparison, then Adjust the parameter m, and repeat step 5 until the ideal measurement result is obtained.

[0046] Finally, when the value of m is 4.00, the effect is the most ideal, the distribution peaks can be clearly distinguished, and the measurement accuracy is improved.

[0047] The particle size distribution of the particles obtained in this example can be found in image 3 Curve 4 in, as a control, image 3 The particle size distribution (curve 5) when m is 2.67, the particle size distribution (curve 7) obtained by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com