Casting construction mold for water-cooled column and water-cooled beam of heating furnace

A water-cooled column and water-cooled beam technology, which is applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve the problems of high cost of steel mold production, easy deviation of water-cooled columns, and increased wooden squares, etc., to achieve improved The effects of pouring quality, elimination of quality hazards, and enhanced versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the present invention, the technical solutions of the present invention will be further described below with reference to the embodiments and accompanying drawings.

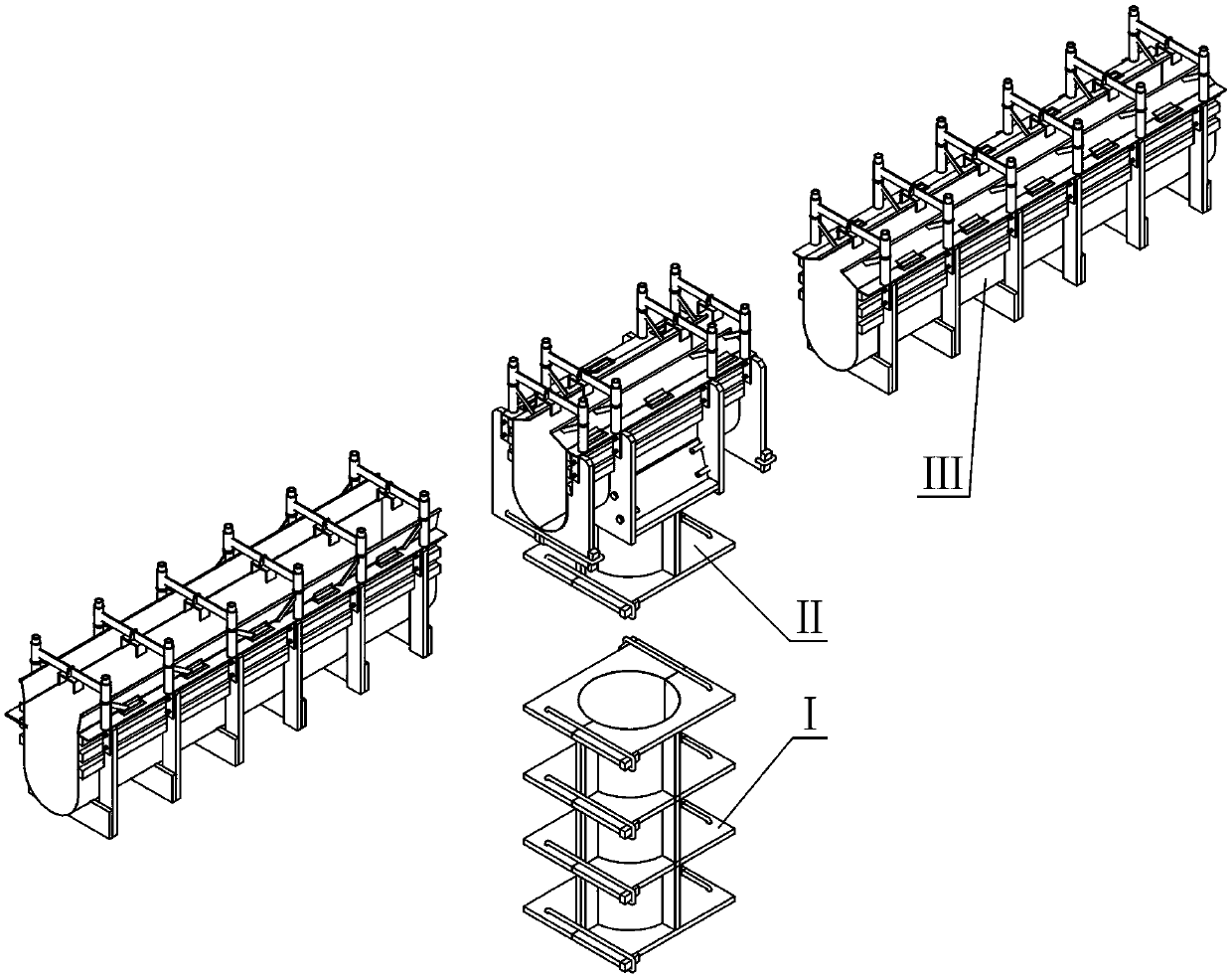

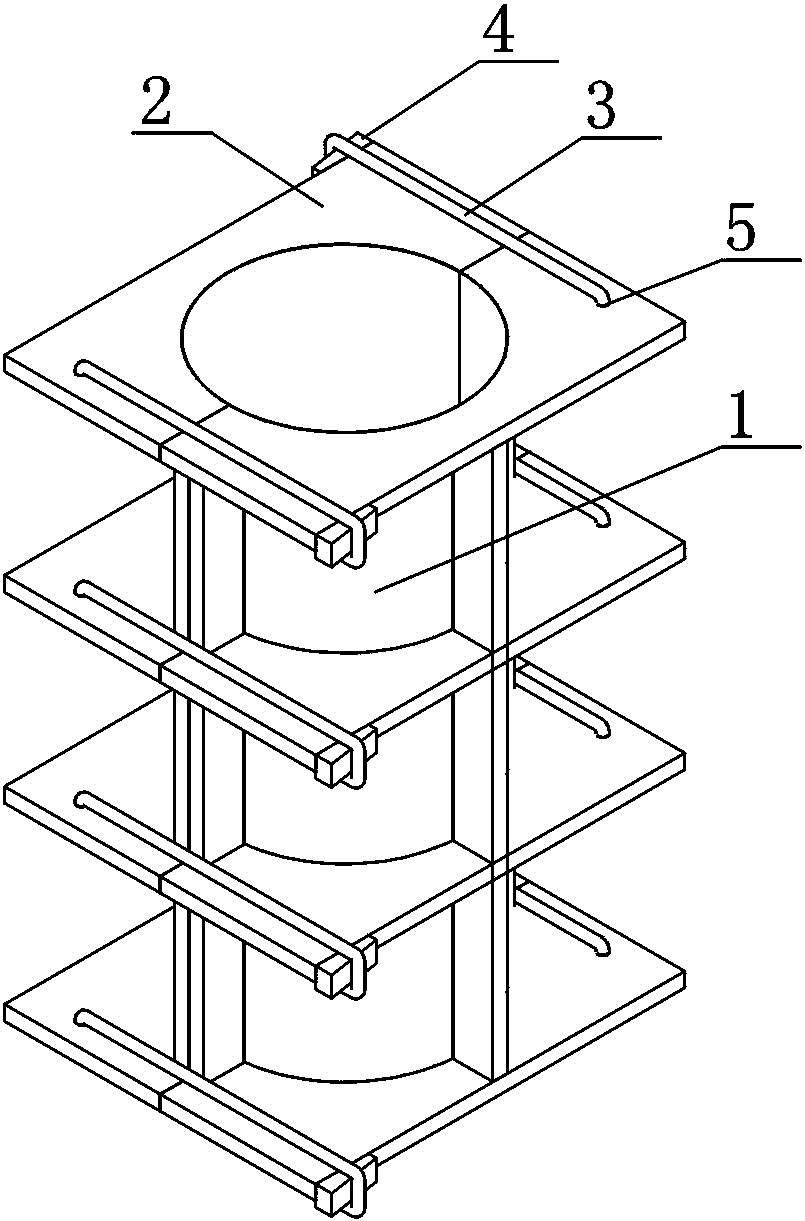

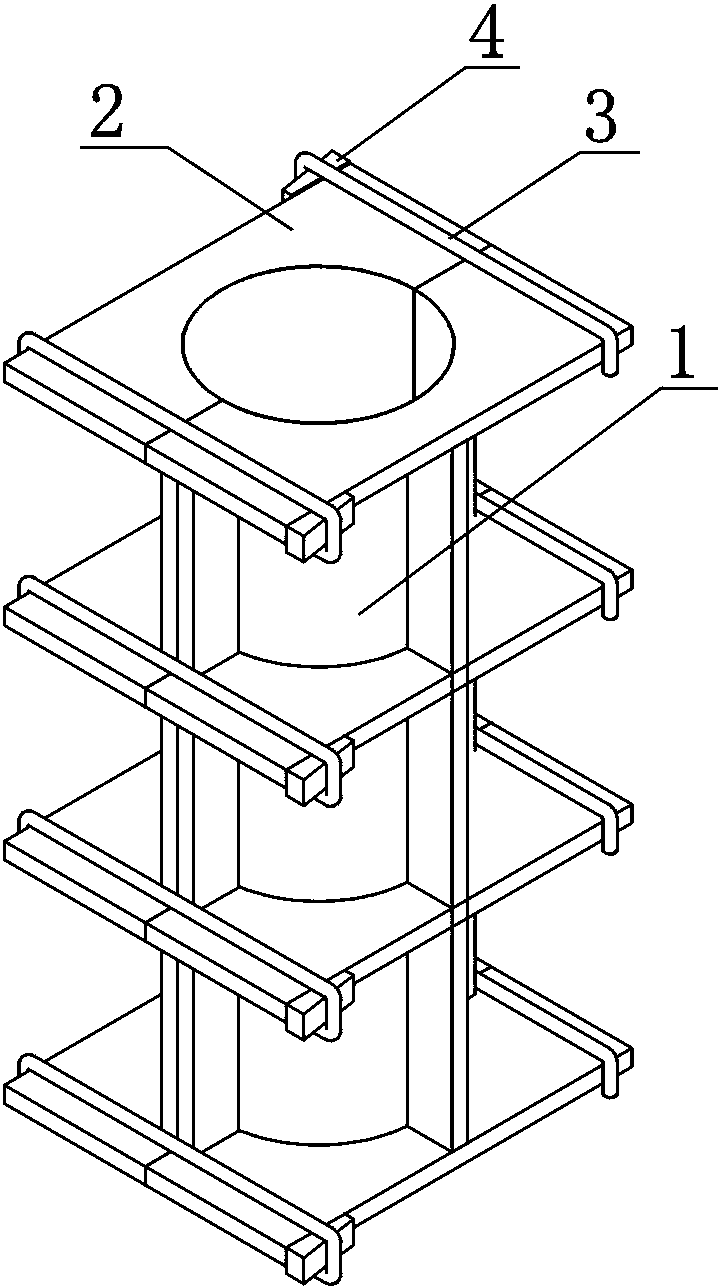

[0032] like Figure 1-12 As shown, a heating furnace water-cooled column and water-cooled beam casting construction mold, which includes a water-cooled column mold I, a three-way mold II and a water-cooled beam mold III, such as figure 2 , 3 As shown, the water-cooled column mold I is mainly assembled from a pair of water-cooled column half-moulds 1. The outer surface of the water-cooled column half-mould 1 is provided with reinforcing ribs in the axial direction, and a plurality of wooden rib plates 2 are evenly arranged in the circumferential direction. (The reinforcing rib is made of wood, and is combined with the wooden rib plate 2 to form a wooden frame), a pair of water-cooled column half-moulds 1 are fixed together by a locking device, and the locking device is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com