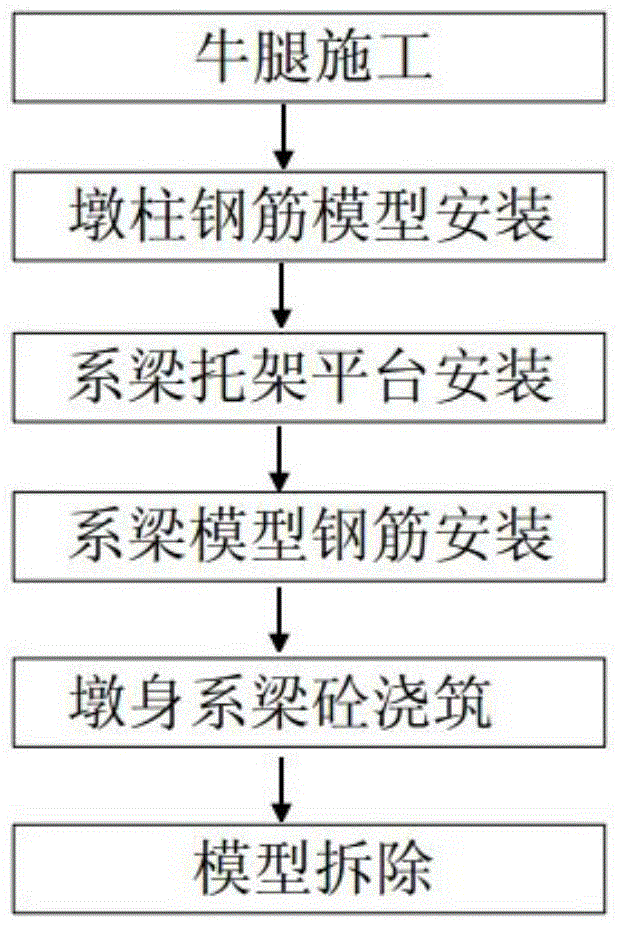

A Synchronous Construction Method of Bridge Pier and Transverse Beam Corbel Bracket

A technology of simultaneous construction and construction method, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. Simultaneous construction, cumbersome construction procedures and other problems, to achieve the effect of less material used, low construction cost, and high turnover rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in combination with specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

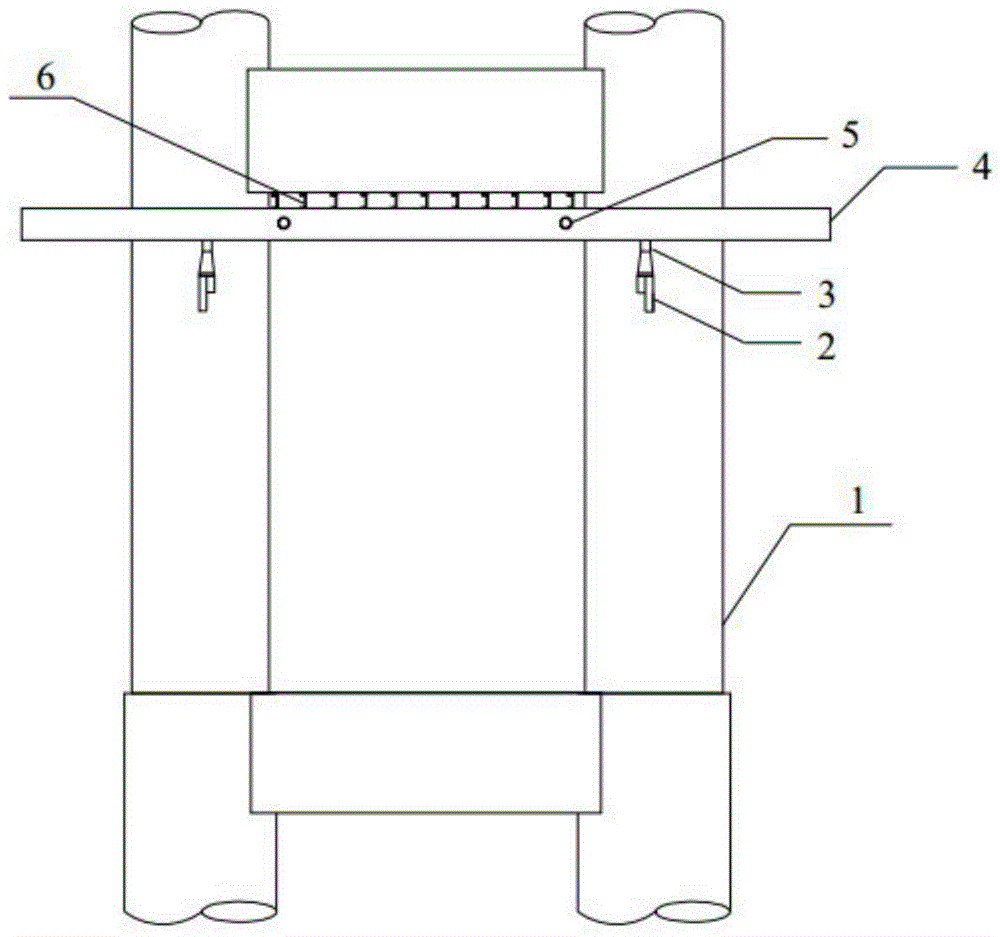

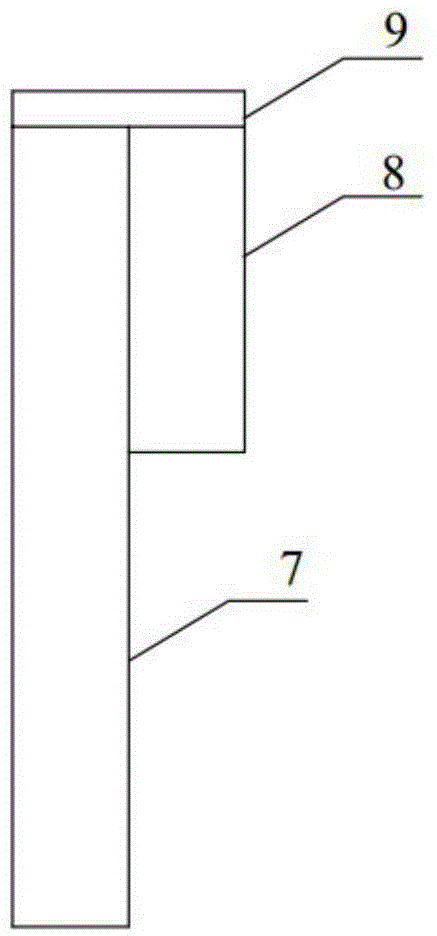

[0044] The construction method described in the present invention is used for the construction of the first contract section of Shankun Expressway Guizhou Jingbanba (Guangxi-Guizhou boundary) to the bottom of the river (Guizhou-Yunnan boundary), 6 bridges, 1 super-large bridge, 5 large bridges, The bridge is 4.31km long, and the tenders are mainly bridge projects. The substructure of the bridge is designed as a cylindrical pier with diameters of 1.8m and 2.0m respectively and a maximum height of 42m. One or two transverse beams are arranged between the pier bodies, and the pier spacing is 6.7m (centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com