Artificial stone and preparation method thereof

An artificial stone and formula technology, applied in the direction of manufacturing tools, supply devices, ceramic molding machines, etc., can solve the problems of poor anti-fouling, low stone strength, low gloss, etc., to improve strength, high simulation, and reduce porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

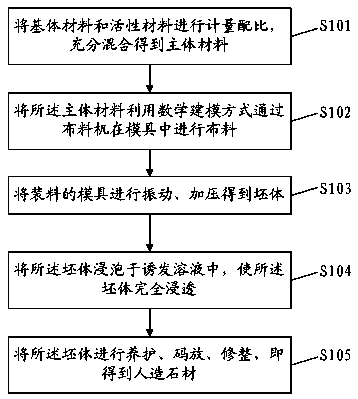

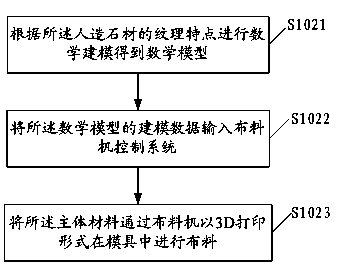

[0082] refer to figure 1 as well as figure 2 , the embodiment of the present invention provides a kind of preparation method of artificial stone, comprising:

[0083] In S101, the matrix material and the active material are measured and proportioned, and the main material is obtained by mixing them thoroughly.

[0084] The formula of the base material in parts by mass is as follows:

[0085] Aggregate 150~800;

[0086] Preferably, the base material also includes an inorganic pigment, and its formula in parts by mass is as follows:

[0087] Inorganic pigment 0~30;

[0088] Further preferably, the formulation of the matrix material in parts by mass is as follows:

[0089] Aggregate 200~650

[0090] Inorganic pigment 0~25.

[0091] The formulation of the active material in parts by mass is as follows:

[0092] Cross-linking agent 200~800;

[0093] Preferably, the active material also includes magnesium chloride and / or silicon micropowder, and its formula in parts by mas...

Embodiment 1

[0127] Embodiment 1, the preparation of artificial marble I

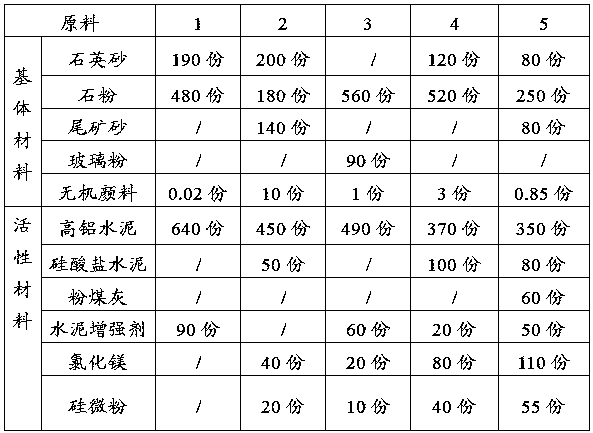

[0128] Matrix material formula: 190 parts of quartz sand, 480 parts of stone powder, 0.02 parts of inorganic pigment.

[0129] Active material formula: 640 parts of high alumina cement, 90 parts of cement reinforcing agent.

[0130] Mix and stir the matrix material and the active material until they are uniform to obtain the main material, unload the main material from the mixer, and put them into multiple feeding hoppers of the distributing machine according to the different inorganic pigments added to the main material, and control the feeding through the gate under the feeding hopper. The feeding order and feeding amount of the hopper. Move the mold with the material to the vibrating table, vibrate for 5s at an amplitude of 0.2 mm and a frequency of 50 Hz, and then pressurize the material on a press to make the material reach a predetermined density to obtain a green body. The green body is soaked in the silica...

Embodiment 2

[0131] Embodiment 2, the preparation of artificial marble II

[0132] Matrix material formula: 200 parts of quartz sand, 180 parts of stone powder, 140 parts of tailings sand, 10 parts of inorganic pigment.

[0133] Active material formula: 450 parts of high alumina cement, 50 parts of Portland cement, 40 parts of magnesium chloride, and 20 parts of silica powder.

[0134] The matrix material and the active material are mixed and stirred until they are uniform to obtain the main material, and the main material is discharged from the mixer, and put into multiple feeding hoppers of the distributing machine according to the different inorganic pigments added to the main material, and the feeding hopper is controlled through the gate under the feeding hopper The feeding sequence and feeding amount. Move the mold with the material to the vibrating table, vibrate for 5s at an amplitude of 0.1 mm and a frequency of 500 Hz, and then pressurize the material on a press to make the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com