Stepped-type crystallization preparation method of titanium-containing molecular sieve

A titanium molecular sieve and stepped technology, which is applied in the synthesis field of titanium-containing molecular sieve, can solve the problems of increasing the dosage of TPAOH and high cost, and achieve the effects of reducing dosage, high production efficiency and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

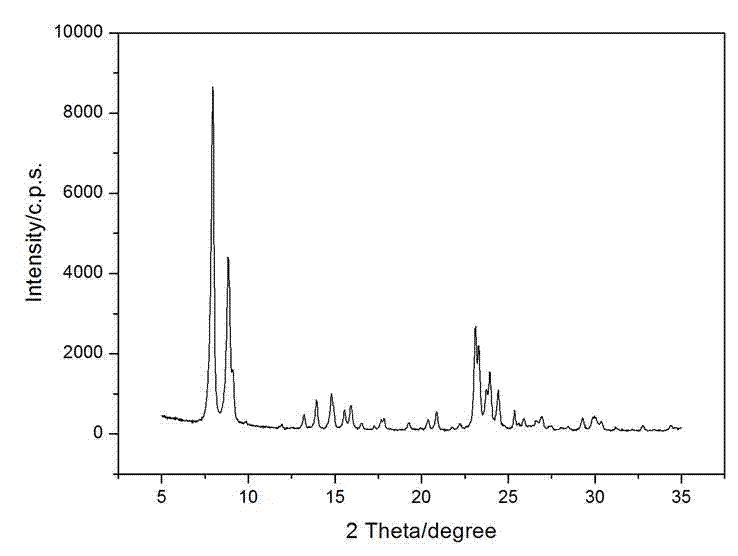

[0030] Add 50g of silica sol (mass fraction 30%) into 85g of tetrapropylammonium hydroxide (mass fraction 25%) solution, stir vigorously to obtain a gel, transfer it to an autoclave, and keep it at 100°C for 24 hours to obtain a Directing agent: Slowly add 3.3g tetrabutyl titanate to the above-mentioned directing agent dropwise within 3 hours, then raise the temperature to 160°C and keep for 36 hours to obtain the product, and obtain Ti-MFI molecular sieve after separation, washing, drying and roasting , the product is labeled A. Its X-ray diffraction pattern has figure 1 Characteristics.

Embodiment 2

[0032] Add 45g of silica sol (mass fraction 30%) to 82g of tetrapropylammonium hydroxide (mass fraction 25%) solution, stir vigorously to obtain a gel, transfer to an autoclave, and keep at 110°C for 24 hours to obtain a Directing agent: Slowly add 3.0g tetraethyl titanate to the above directing agent dropwise within 5 hours, then raise the temperature to 170°C and keep for 24 hours to obtain the product, and obtain Ti-MFI molecular sieve after separation, washing, drying and roasting , the product is labeled B. Its X-ray diffraction pattern has figure 1 Characteristics.

Embodiment 3

[0034] Add 68g of silica sol (mass fraction 30%) to 80g of tetrapropylammonium hydroxide (mass fraction 25%) solution, stir vigorously to obtain a gel, transfer to an autoclave, and keep at 120°C for 12 hours to obtain a Directing agent: Slowly add 4.5g tetrabutyl titanate to the above-mentioned directing agent dropwise within 3 hours, then raise the temperature to 170°C and keep for 30 hours to obtain the product, and obtain Ti-MFI molecular sieve after separation, washing, drying and roasting , the product is labeled C. Its X-ray diffraction pattern has figure 1 Characteristics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com