Preparation method of graphene transparent conductive film

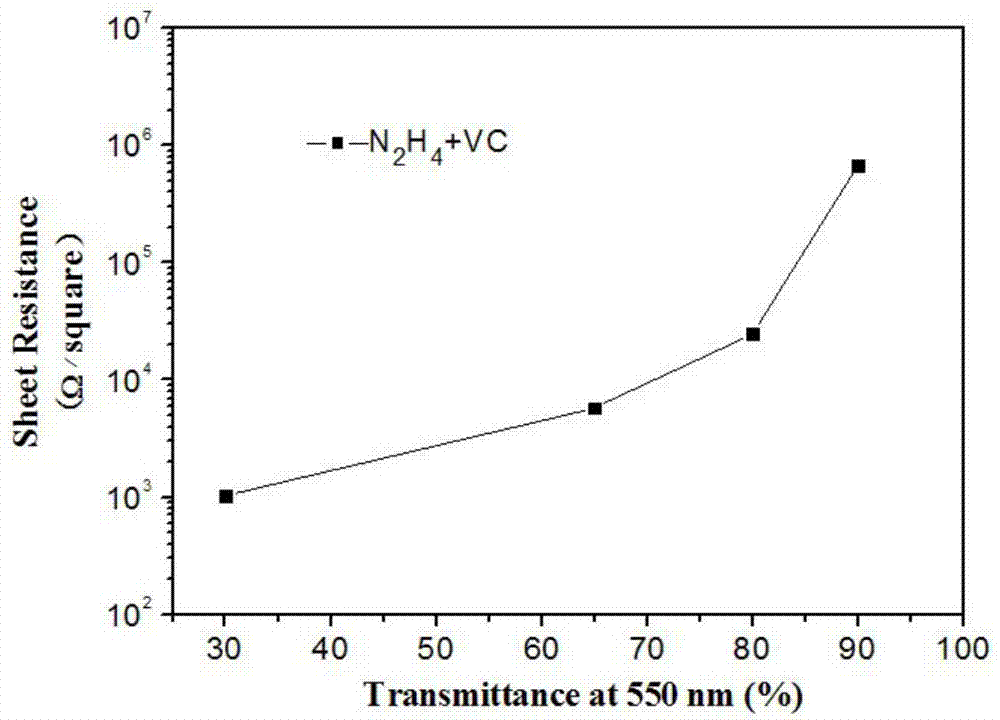

A technology of transparent conductive film and graphene, which is applied in the direction of graphene, cable/conductor manufacturing, chemical instruments and methods, etc., can solve the problems of high heat treatment temperature, low utilization rate of raw materials, poor reduction effect, etc., and achieve simple preparation method, The effect of controllable film thickness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

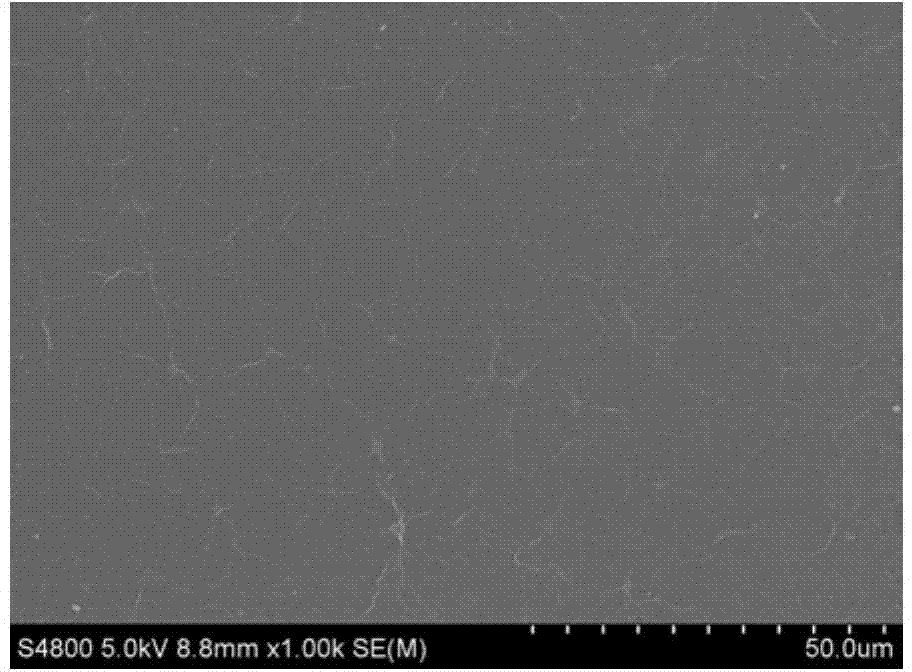

Image

Examples

Embodiment 1

[0015] A preparation method of graphene transparent conductive film, comprising the following steps:

[0016] (1) Preparation of graphite oxide: first measure 138ml concentrated H 2 SO 4 Pour into ice bath, then add 1.5g graphite powder and 0.75g NaNO 3 , magnetically stirred for 30min; then slowly added 4.5g KMnO 4 , the reaction mixture was magnetically stirred in a water bath at 35°C for 12h; then 4.5g KMnO was added slowly 4 , control the reaction temperature at 35°C, continue magnetic stirring for 12h; pour the reaction mixture into a beaker filled with about 200ml of ice cubes, stir continuously with a glass rod, and then add 30% H 2 o 2 Until the solution is golden yellow; then filter while it is hot, wash once with 5% HCl, and then wash with deionized water until the solution is neutral, then centrifuge at a speed of 5000rpm for 7min to remove large particles and graphite that is not completely oxidized; finally, After ultrasonic treatment for 5 minutes, it was po...

Embodiment 2

[0022] A preparation method of graphene transparent conductive film, comprising the following steps:

[0023] (1) Preparation of graphite oxide: first measure 130ml concentrated H 2 SO 4 Pour into ice bath, then add 1.5g graphite powder and 0.75g NaNO 3 , magnetically stirred for 30min; then slowly added 4.5g KMnO 4 , the reaction mixture was magnetically stirred in a water bath at 35°C for 10 min; then 4.5 g of KMnO was added slowly 4 , control the reaction temperature to 35° C., and continue magnetic stirring for 10 h. Pour the reaction mixture into a beaker filled with about 200ml of ice cubes, stir continuously with a glass rod, and then add 30% H 2 o 2 until the solution turns golden yellow. Then filter while it is hot, wash once with 5% HCl, and then wash with deionized water until the solution is neutral, then centrifuge at a speed of 5000rpm for 7min to remove large particles and graphite that has not been completely oxidized; finally, after 5min ultrasonic treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com