Distribution line pipe joint height adjustment device

A technology of height adjustment device and pipe joint, which is applied in the field of elevators, can solve the problems of large impact force between the lifting part and the supporting part, reduce the service life of the elevator, damage the lifting part, etc. The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

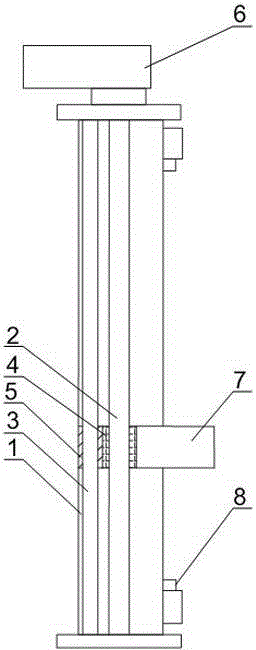

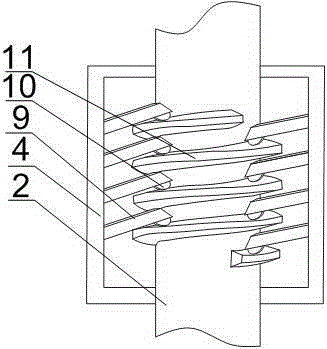

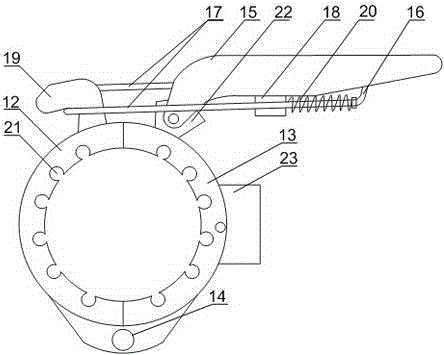

[0025] Such as Figure 1 to Figure 3As shown, the height adjustment device for distribution line pipe joints of the present invention includes a lifting column 1, a screw 2 and a guide rod 3 are installed in the lifting column 1, and a driving mechanism is connected to the upper end of the screw 2. There is a rectangular hole on the lifting column 1, and a rotating cylinder 4 is installed on the screw mandrel 2. A plurality of support blocks 9 are arranged in the rotating cylinder 4, and the support blocks 9 are distributed along the rotation direction of the thread 11 on the screw mandrel 2. The inner wall of the cylinder 4 has a groove at the bottom of the support block 9, and a roller 10 is rotated in the groove, and the roller 10 is engaged with the screw thread 11 on the screw rod 2, and a guide sleeve 5 is connected to one end of the rotating cylinder 4, The guide sleeve 5 is slidably arranged on the guide rod 3, and the other end of the rotating cylinder 4 is also conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com