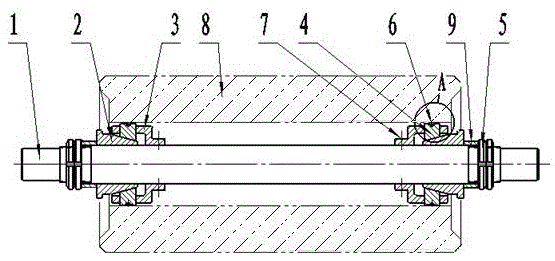

A special fixture for cylindrical processing of long cylindrical parts

A technology for special fixtures and parts, which is applied in the field of special fixtures for cylindrical processing of long cylindrical parts, can solve problems such as difficult control of machining accuracy, achieve high centering accuracy and improve versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

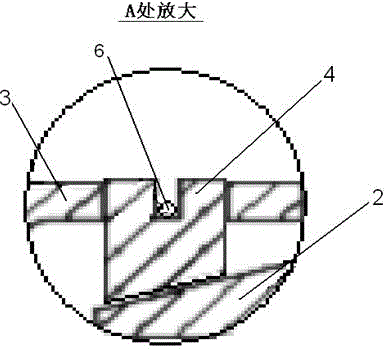

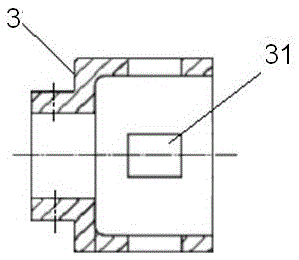

[0015] Example: A preferred embodiment of the present invention is as follows, as Figure 1 to Figure 4 As shown, a special fixture for cylindrical processing of long cylindrical parts is composed of the following components. The mandrel 1 is one piece, the shaft sleeve 9, the taper sleeve 2 and the guide sleeve 3 are each two pieces, and the top block 4 is eight pieces. Ring spring 6 is two pieces, set screw 7 is eight pieces, and lock nut 5 is four pieces. The guide sleeve 3 has a large and small end structure, and its small end is fixed on the mandrel 1 through four set screws 7. At least one set of through holes is symmetrically arranged on the large end sleeve of the guide sleeve 3. In this embodiment, two groups of four through holes are symmetrically arranged. through hole. The top block 4 is installed in the through hole, the outer end of the top block 4 is an arc surface, the inner end of the top block 4 is provided with a tapered surface, the outer end with the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com