A reciprocating winding device for processing spiral core rolls

A winding device and spiral technology, which is used in the field of machinery and equipment manufacturing in the disposable hygiene product industry, can solve the problems of frequent increase in replacement material rolls, speeding up the use of single-roll core materials, and increasing overall machine instability. , to achieve the effect of low labor cost, increased storage length and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

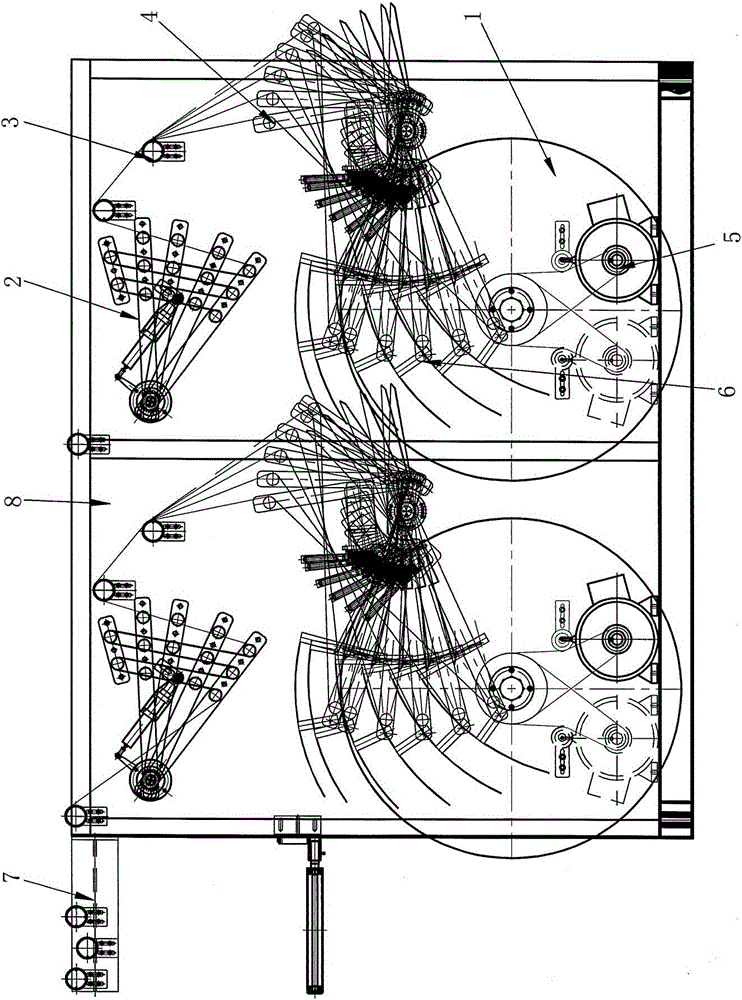

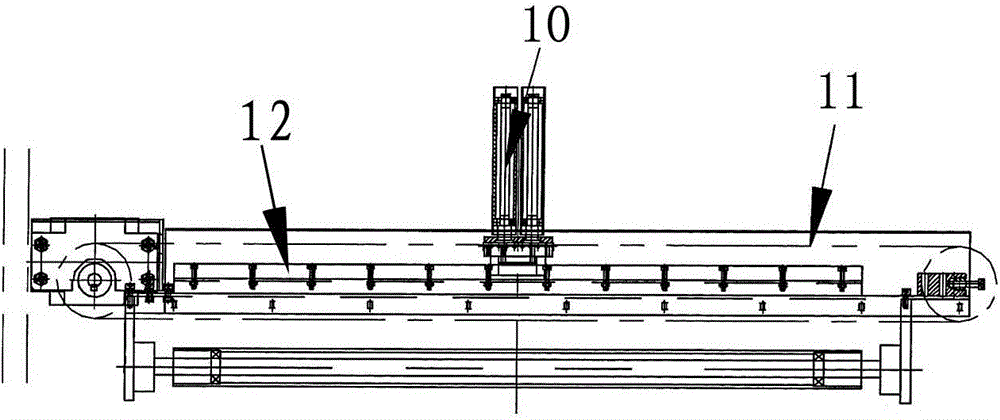

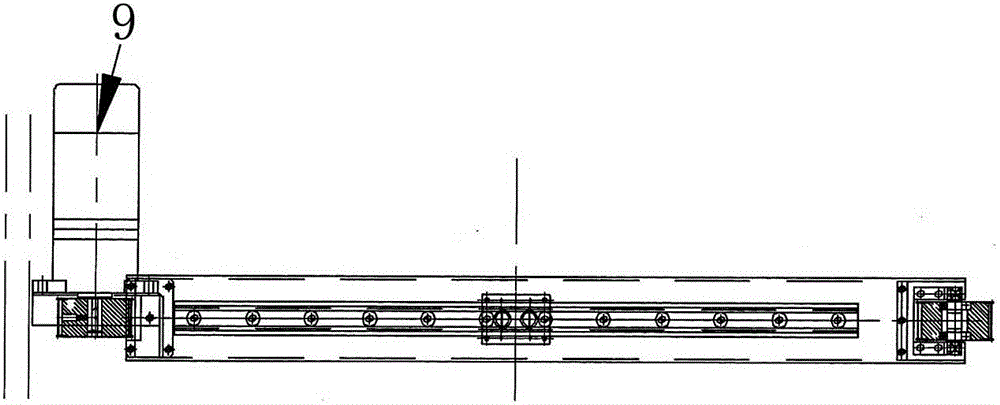

[0027] Such as figure 1 As shown, a reciprocating winding device for processing spiral core rolls is composed of an air expansion shaft device 1, a tension swing rod 2, a transition roller 3, a pressing swing rod device 4, a motor 5, a swing frame 6, Support seat 7, frame 8 are formed, it is characterized in that,

[0028] The frame 8 is vertically placed on the load-bearing surface, and a plurality of motors 5 are fixedly arranged on the bottom of the inside of the frame 8, and a plurality of inflatable shaft devices 1 are fixedly arranged in the lower part of the wallboard, and the shaft ends of the motors 5 are connected with the inflatable shaft through the conveyor belt. The inner shaft end of the shaft device 1 realizes the transmission connection;

[0029] The middle part of the wall panel is provided with a pressing swing rod device 4, which is located obliquely above the air expansion shaft device 1, and the pressing swing rod device 4 is connected with the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com