Underwater suspension type mooring winch

A mooring winch and suspension type technology is applied in the field of underwater robot operation devices, which can solve the problems of unfavorable service life of slip rings, excessive axial size of the winch, and easy occurrence of mechanical failures, etc., so as to facilitate wiring operations and save installation space. , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

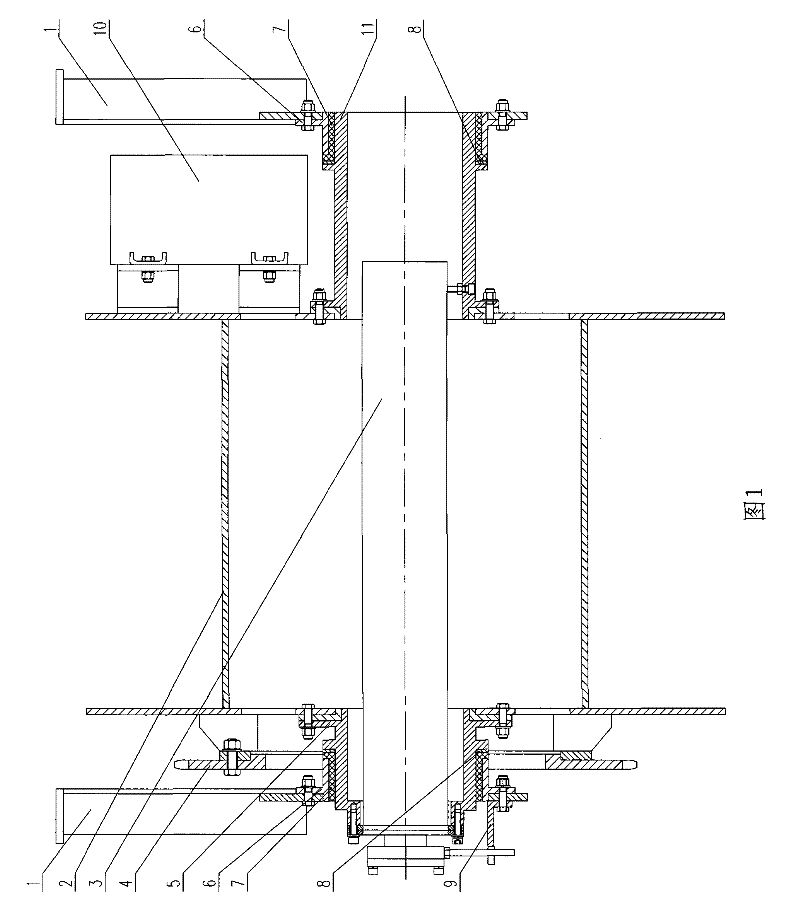

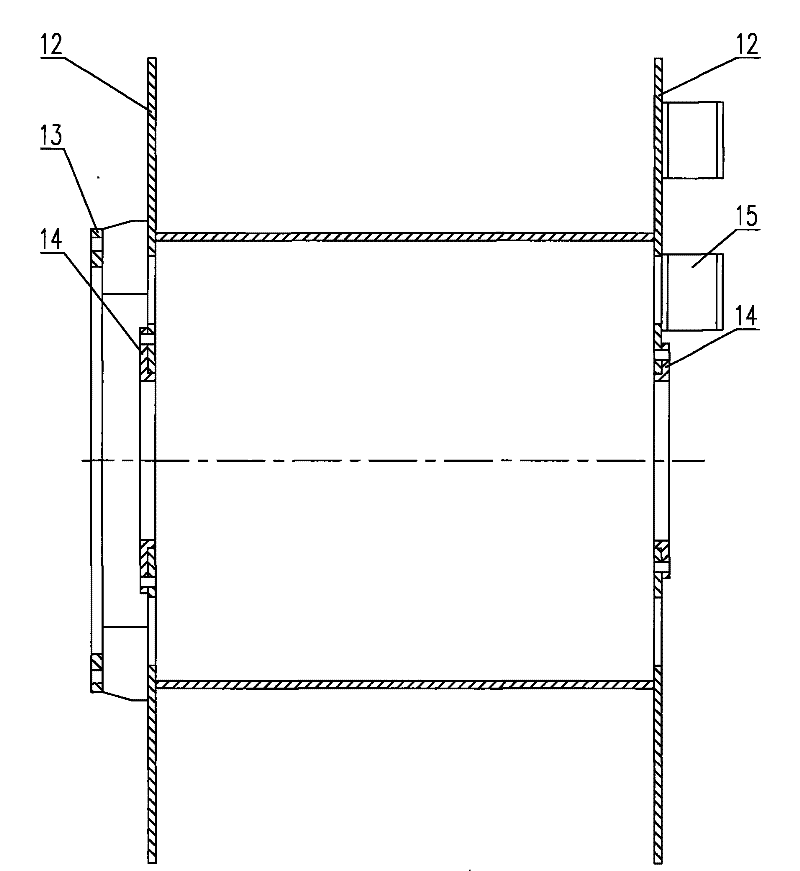

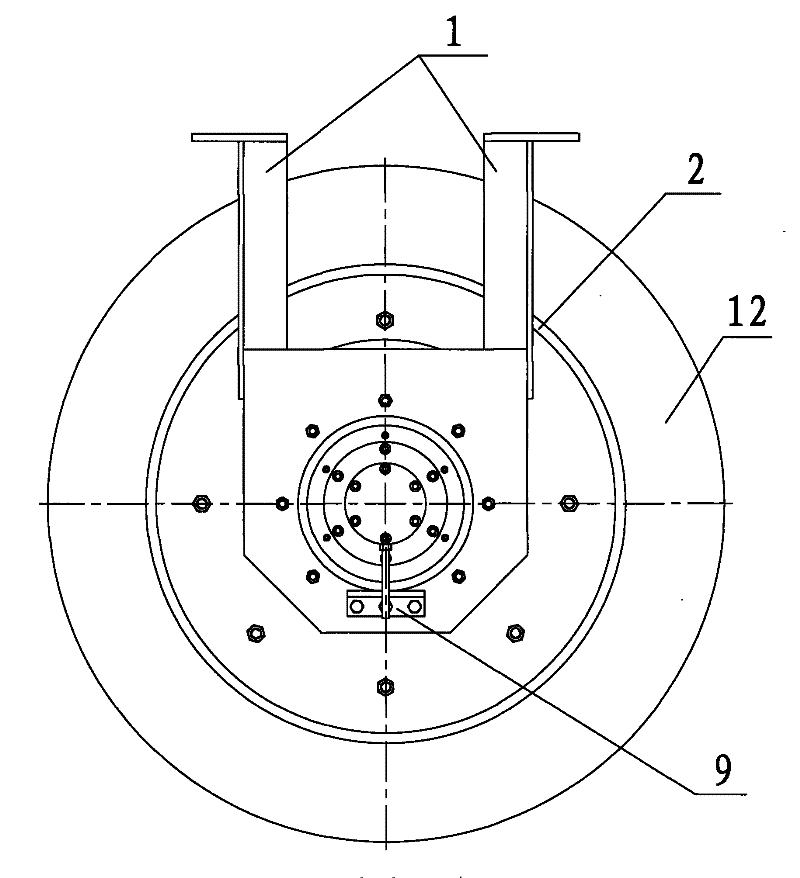

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] like Figure 1~3 As shown, the present invention includes a reel 2 and a slip ring 3 (commercially available products, the present embodiment adopts the FOCAL176 model). The interior of the reel 2 is a cavity structure, and there are side plates 12 on both sides, a round hole is opened in the center, and a process hole is also opened on it, and the flange 14 is installed on the side plates on both sides through the central round hole, wherein A sprocket connection flange 13 is also provided on one side plate, and a connecting seat 15 is provided on the other side plate. The flange 14 on one side of the reel 2 is fixedly connected with the first inner connecting bushing 5, the outer surface of which is covered with a sliding sleeve 7, and the outer connecting bushing 6 is sleeved on the outer surface of the sliding sleeve 7; the reel 2 The flange 14 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com