Cable winding device

A cable winding and cable routing technology, which is used in cable laying equipment, the arrangement of reels/photosensitive drums, etc., can solve the limitation of the operating depth of the underwater robot carrier, the limited length of the storage cable, and the high requirements of operators. problems, to achieve the effect of ensuring service life, compact structure, and increasing storage length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

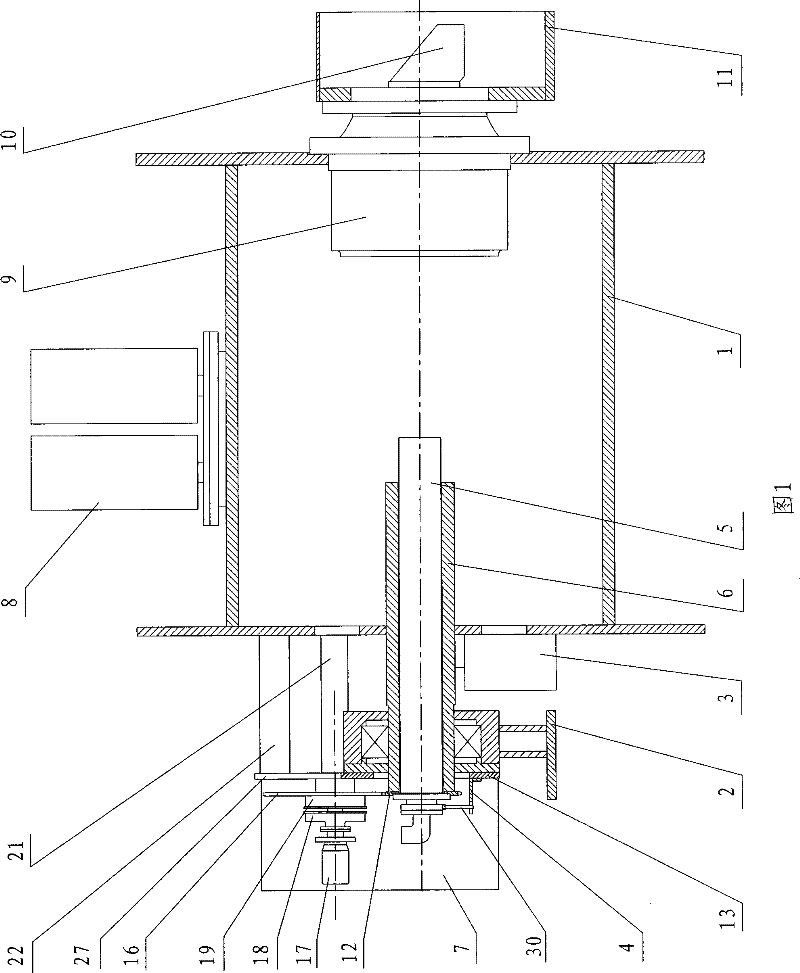

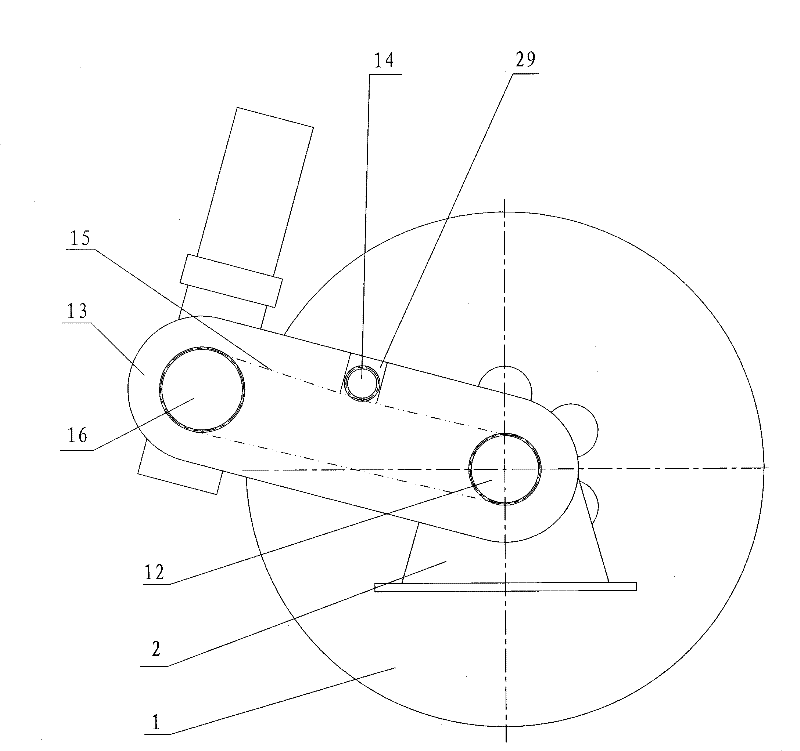

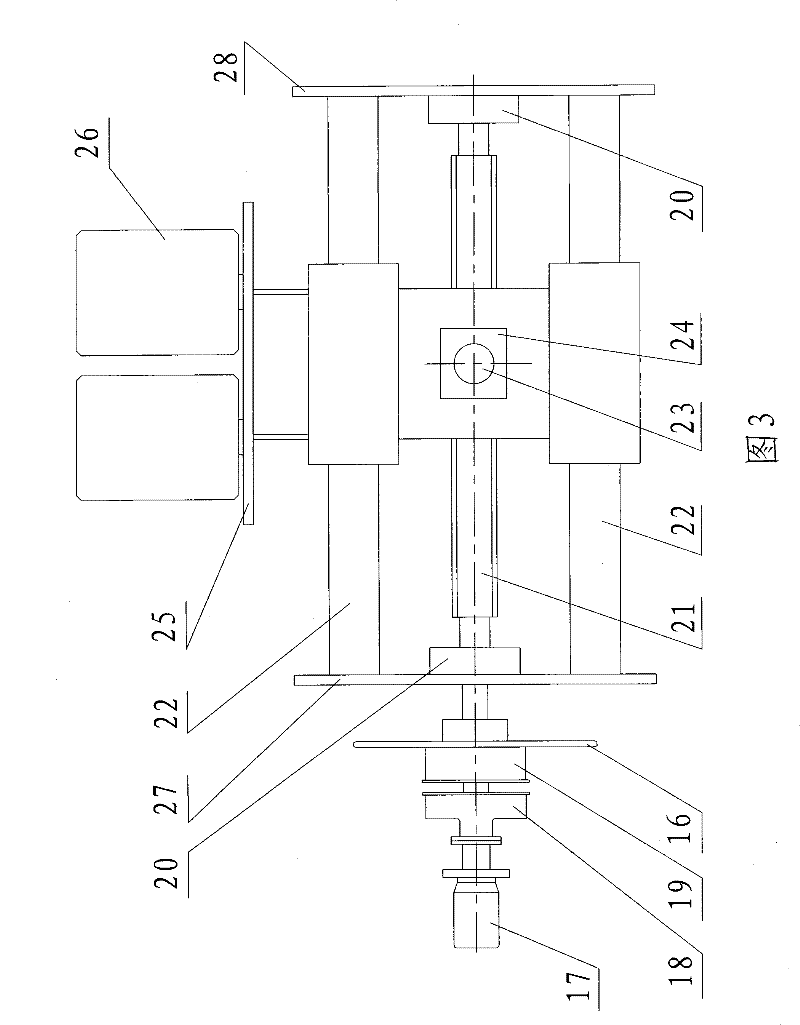

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] Such as Figure 1~3 As shown, the present invention includes a reel 1, a slip ring 5, a reel bushing 6, a cable router 8, a reducer 9 and a motor 10. There are round holes for installing the reel shaft sleeve 6 and the reducer 9 at the center of both ends of the cylinder 1, and the reel 1 on the side where the reel shaft sleeve 6 is installed is also provided with a process hole. The reel bushing 6 is coaxially installed on one end of the reel 1 through the center hole 1 at one end, and the reducer 9 is fixedly connected to the center hole 1 at the other end of the reel 1, and the motor 10 is fixedly connected to the end face of the reducer 9 Above, the reducer support 11 is sleeved on the outer surface of the reducer 9; a support 2 is sleeved on the reel shaft sleeve 6 outside the reel 1, and the outer end surface of the support 2 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com