Buffering roller device

A technology of rollers and roller racks, applied in the directions of rollers, transportation and packaging, conveyors, etc., can solve the problems of high cost of use, smashing and falling off of the glue layer, poor glue injection, etc., so as to reduce the maintenance cost and prolong the use. Longevity and good buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

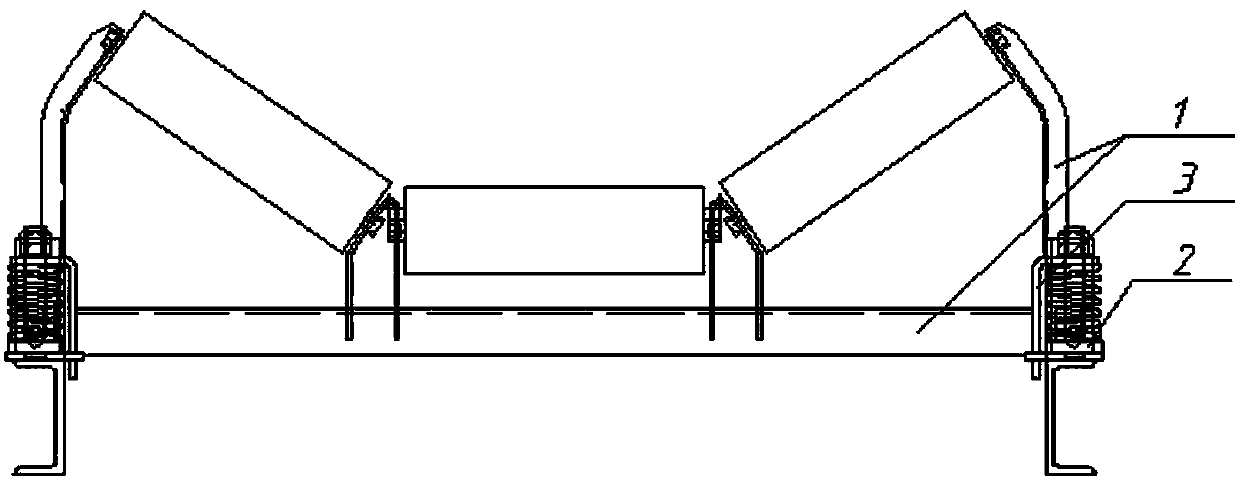

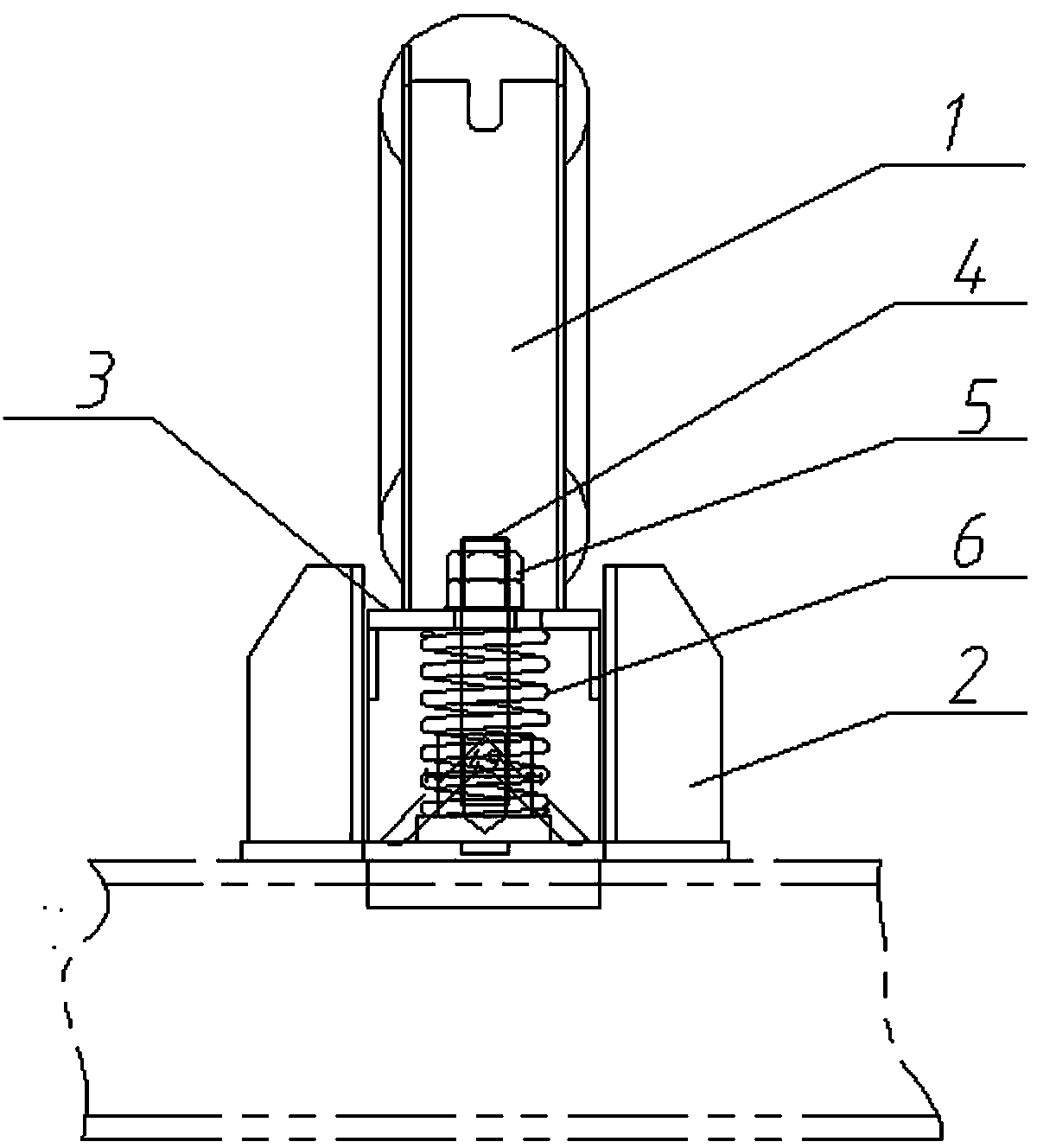

[0010] Such as figure 1 , figure 2 The buffer idler device shown includes a roller frame 1, a U-shaped groove 2, a support frame 3 and an elastic device. The supporting frame 3 is connected with the idler frame 1.

[0011] Such as figure 2 As shown, the elastic device includes a spring 6, a bolt 4 and an adjusting nut 5, the bolt 4 passes through the support frame 3 and is fixed at the bottom of the U-shaped groove 2, and the spring 6 is sleeved on the bolt 4 at the bottom of the support frame in the U-shaped groove, The nut 5 is screwed on the bolt 4 at the upper end of the support frame.

[0012] When in use, adjust the adjusting nut 5 to an appropriate position according to the impact force of the blanking, and give the spring 6 a suitable preload. When the belt conveyor is subjected to the impact force of the blanking, the idler frame 1 is supported The frame 3 transmits the impact force to the spring 6. At this time, the spring 6 rebounds and plays a good buffering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com