Plastic particle feeding device of cable processing device

A technology for plastic granules and processing equipment, which is applied in the field of plastic granule feeding devices for cable processing equipment, which can solve problems such as increased labor intensity of employees, inability to feed pre-dehumidification, and inability to automatically feed materials, so as to reduce labor intensity of employees and improve dehumidification Efficiency, good dehumidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

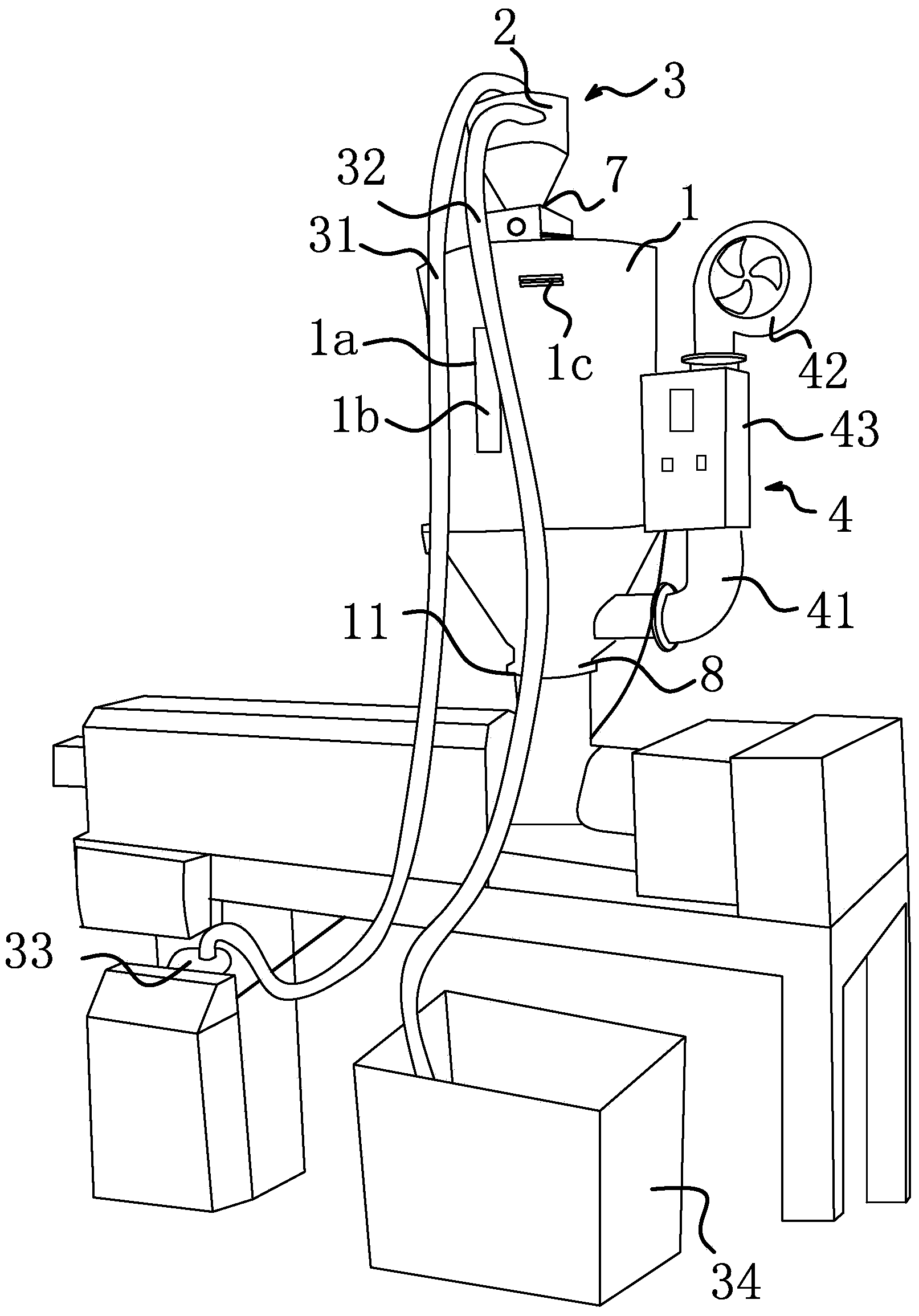

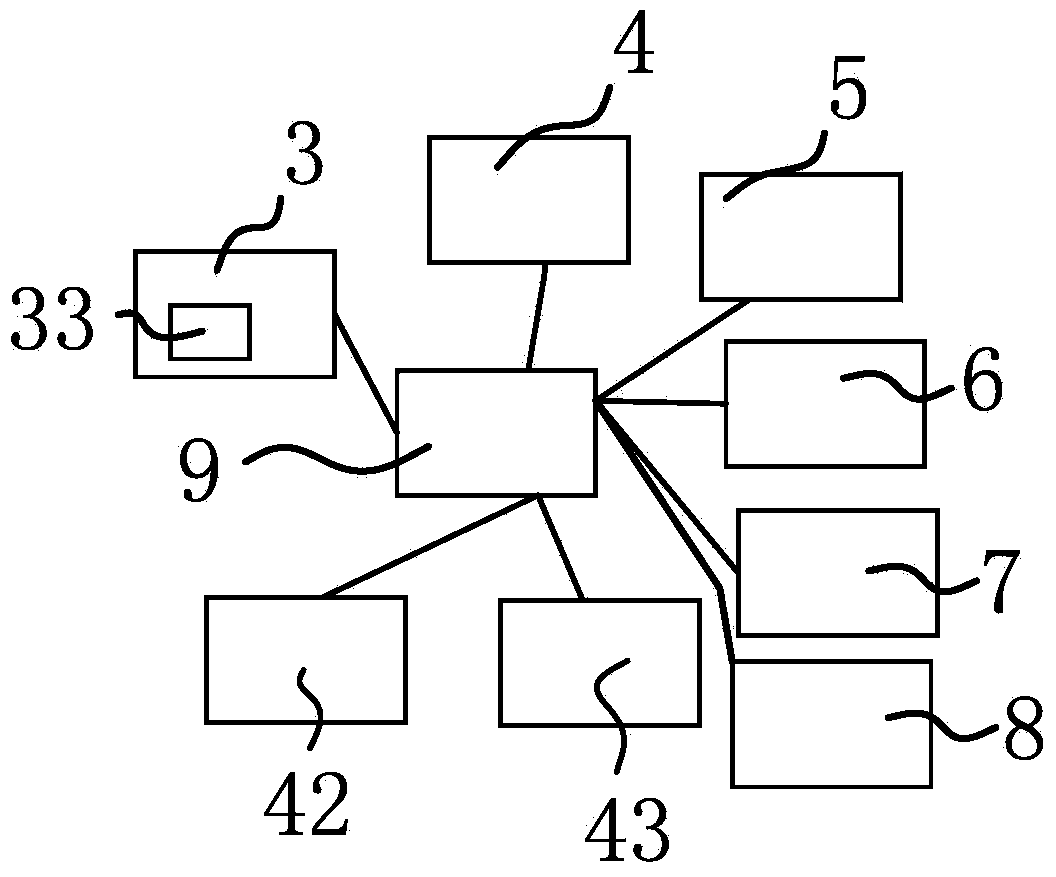

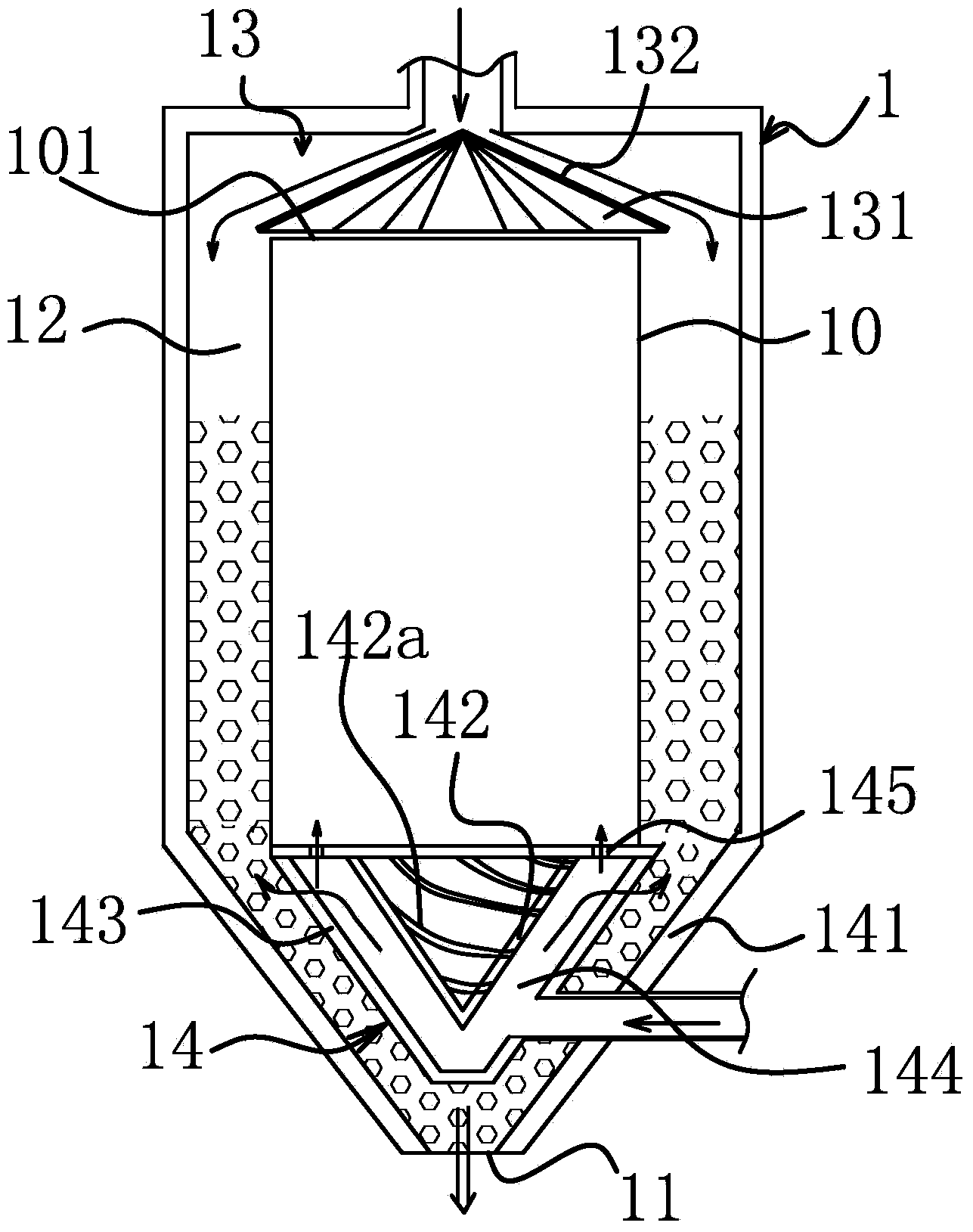

[0026] Such as Figure 1-3 As shown, the plastic particle feeding device of the cable processing equipment includes a storage tank 1, a feeding tank 2 is arranged on the top of the storage tank 1 and the bottom of the feeding tank 2 is connected to the top of the storage tank 1, The bottom of the storage tank 1 is provided with a discharge port 11, which is characterized in that the feed tank 2 is connected with a negative pressure feeding mechanism 3, and the bottom of the storage tank 1 is provided with a device capable of conveying hot air into the storage tank 1. The hot air drying mechanism 4, the storage tank 1 is provided with a storage volume detector 5 for detecting the storage capacity of plastic particles in the storage tank 1 and a humidity sensor 6 for detecting the humidity in the storage tank 1, and the feeding barrel The bottom of 2 is provided with a first electric control valve 7, and the discharge port 11 of the storage tank 1 is provided with a second elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com