Rapid forging press servo direct-drive hydraulic system

A technology of hydraulic system and forging press, which is applied in the field of fast forging hydraulic unit drive control in the forging industry, can solve the problems of high oil cleanliness, high use and maintenance costs, harsh use conditions, etc., to improve the production environment and improve efficiency. , the effect of fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

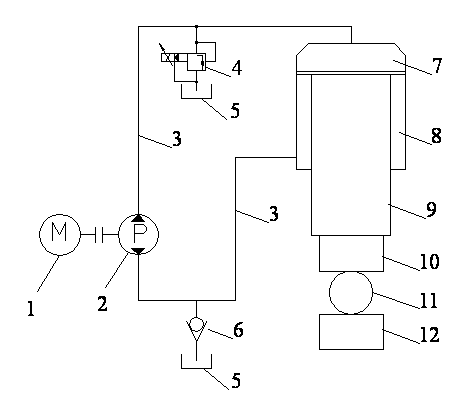

[0014] figure 1 It is a schematic diagram of the composition of the servo direct drive hydraulic system of the rapid forging press proposed by the present invention. The hydraulic system of the whole rapid forging press is mainly composed of the master cylinder piston rod 9, the two-way quantitative pump 2, the servo motor 1, the proportional overflow valve 4, the one-way valve 6 and the hydraulic pipeline 3; the servo motor 1 is connected and drives the two-way quantitative pump 2 to run , the oil outlet and the oil inlet of the two-way quantitative pump 2 are respectively connected to the rodless cavity 7 and the rod cavity 8 of the master cylinder of the press. The press presses down when the rodless chamber 7 enters oil and the rod chamber 8 discharges oil; the press returns when the rod chamber 8 enters oil and the rodless chamber 7 discharges oil. In this way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com