Copper pipe section drawing device

A segmental stretching and copper tube technology, which is applied in the field of stretching devices and copper tube segmental stretching devices, can solve the problems of easy leakage, pipe wall thickness, rough appearance, etc., and achieve reduced noise and high production efficiency , Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

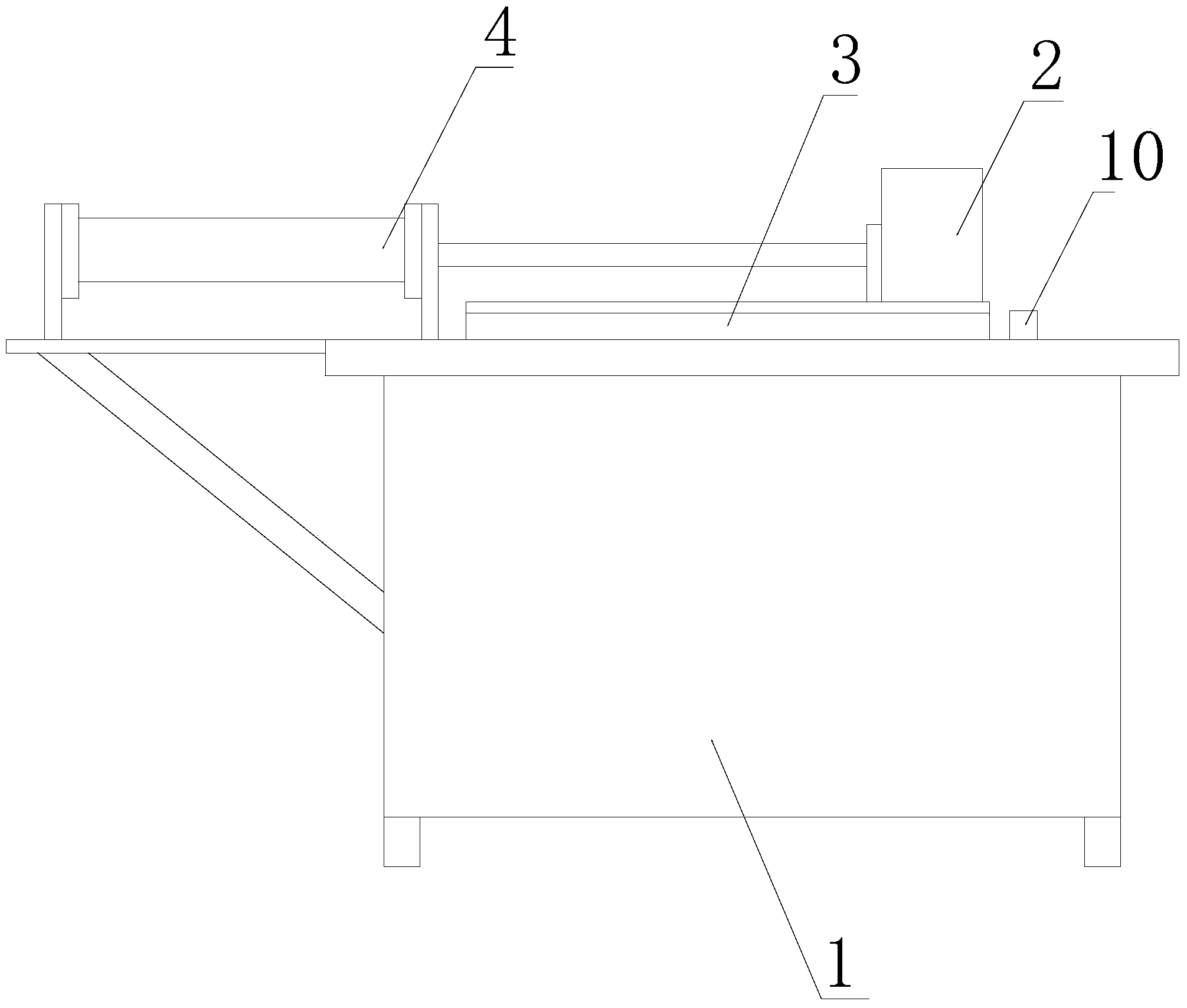

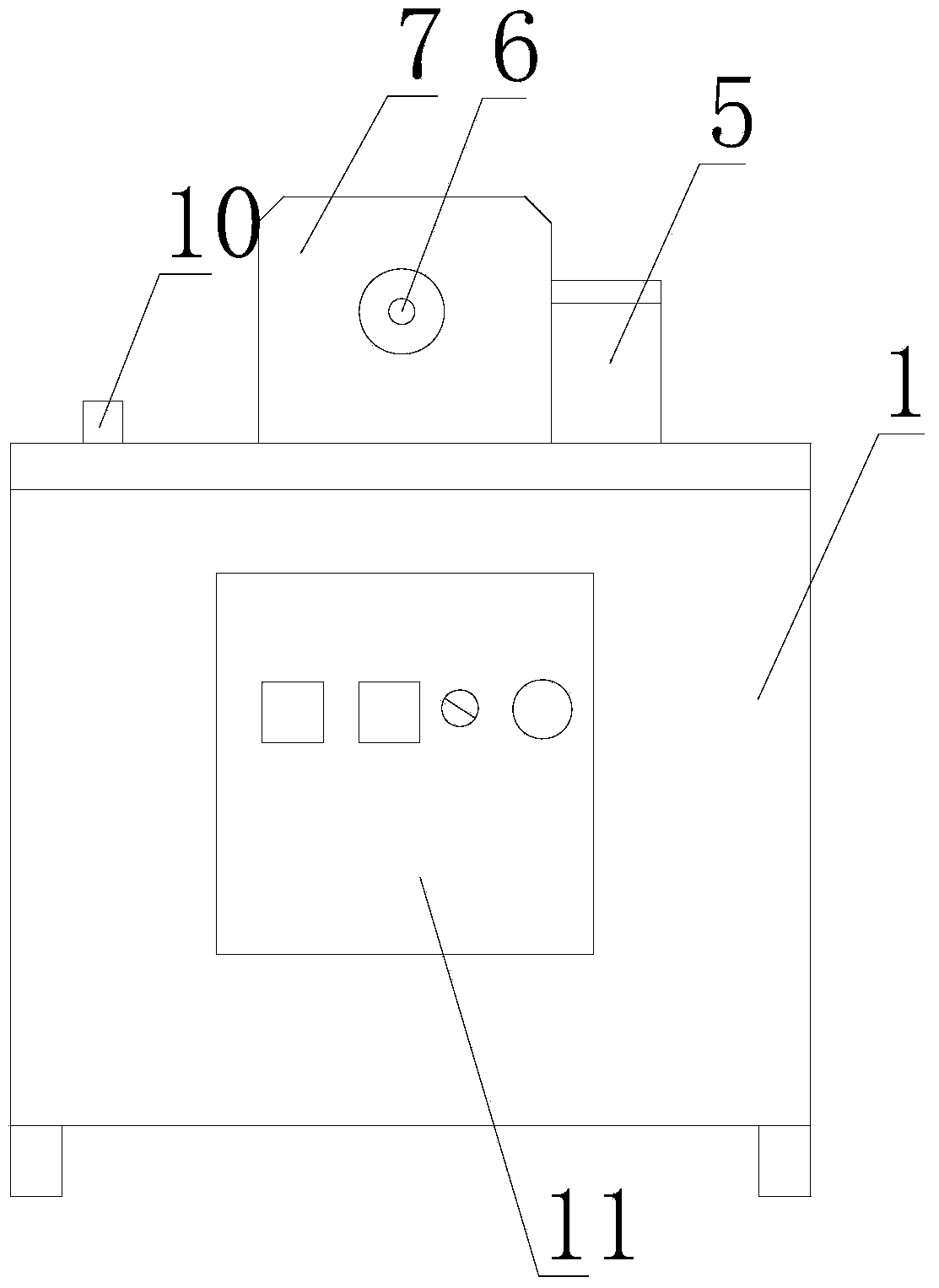

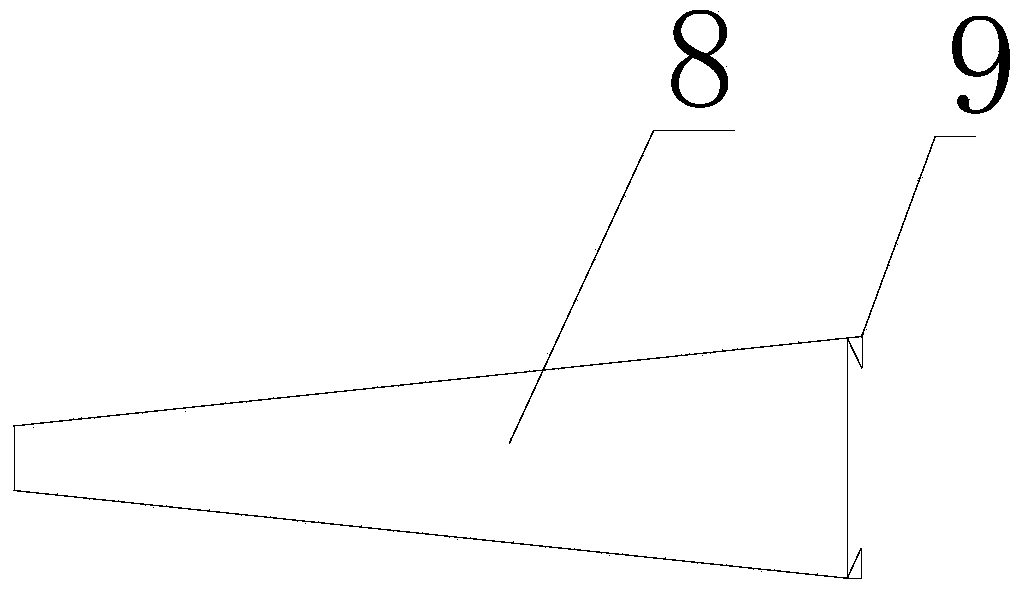

[0025] Such as Figure 1 to Figure 3 As shown, pass the copper pipe that needs to be stretched in sections through the fixed chuck 6, adjust the fixed chuck 6, tighten the copper pipe, open the PLC controller 11 and the high-pressure oil pump 5, so that the PLC controller 11 controls the high-pressure oil pump 5, Adjust the contraction of the cylinder 4 through the high-pressure oil pump 5, thereby driving the stretching of the steel pipe, and sensing the stretching length of the copper pipe through the displacement sensor 10. The stretching length needs to be input into the PLC controller 11 in advance. When the section of the copper pipe stretches to the required After the length, loosen the fixed chuck 6, adjust the position of the copper tube, clamp the end of the other section of the copper tube that needs to be stretched by the fixed chuck 6, tighten the fixed chuck 6, and repeat the previous step; when the entire copper tube After the stretching is finished, the copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com