Non-destructive stripping unit for metal rubber composite parts

A technology of metal rubber and composite parts, which is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unreasonable separation and application of metal rubber composite parts, waste gas environmental pollution, poor practicability, etc., and save manpower , Improve economic benefits and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

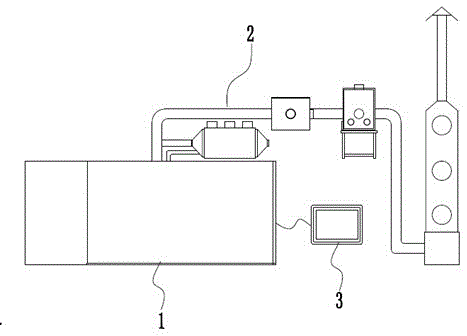

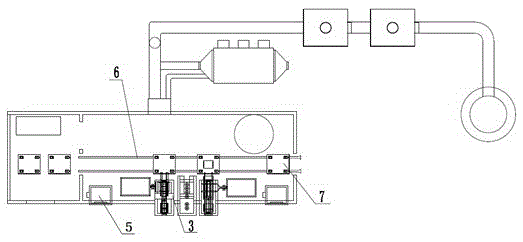

[0031] Example 1, such as Figure 1-5 As shown, a metal-rubber composite non-destructive stripping unit described in the embodiment of the present invention includes:

[0032] Degumming device 1 for heating and cooling metal-rubber composite parts;

[0033]The smoke treatment device 2 connected with the degumming device;

[0034] A man-machine interface control device 3 for controlling the temperature in the degumming device.

[0035] The non-destructive stripping unit for metal-rubber composite parts eliminates the environmental pollution caused by stripping steel parts by burning metal-rubber composite parts in the prior art, and ensures the source quality of accessories. For the transportation industry, the stripping unit provided by the present invention It satisfies the requirements for safe running of railway transportation and reduces the maintenance cost of freight cars. The non-destructive stripping technology using super-audio frequency induction heating equipment...

Embodiment 2

[0039] Example 2, such as Figure 1-5 As shown, the metal-rubber composite non-destructive stripping unit described in the embodiment of the present invention includes:

[0040] Degumming device for heating and cooling metal-rubber composite parts;

[0041] A smoke treatment device connected to the degumming device;

[0042] A man-machine interface control device for controlling the temperature in the degumming device.

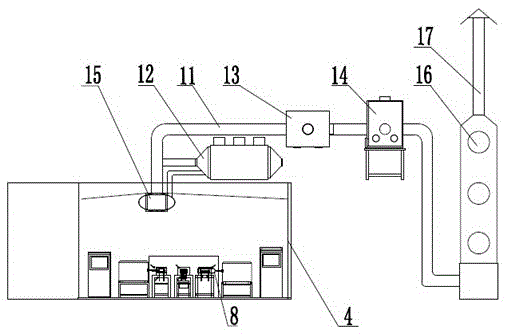

[0043] Further, the smoke treatment device includes a smoke exhaust pipe 11, the smoke exhaust pipe is installed on the top of the degumming chamber, and the smoke exhaust pipe is sequentially connected with a smoke dust purifier 12, a UV photolysis gas purification device 13, and Activated carbon gas purifier 14, the smoke inlet of the smoke exhaust pipe is connected to the smoke gas collection device 15, the end of the smoke exhaust pipe is connected to the water washing filter device 16, and the top of the water washing filter device is connected to the c...

Embodiment 3

[0050] Example 3, such as Figure 1-5 As shown, the metal-rubber composite non-destructive stripping unit described in the embodiment of the present invention includes:

[0051] Degumming device for heating and cooling metal-rubber composite parts;

[0052] A smoke treatment device connected to the degumming device;

[0053] A man-machine interface control device for controlling the temperature in the degumming device.

[0054] Further, the stripping unit also includes a security monitoring device 10, the security monitoring device includes a camera and a display screen, the camera is installed in the degumming device and the smoke processing device, and the camera is connected to the display screen in communication.

[0055] The monitoring status information of the security monitoring device is mainly divided into: data collection of heating temperature of metal rubber parts; data collection of mechanical arm transporting metal rubber composite parts to the working platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com