A mine-used differential high crushing ratio four-roller tooth crusher

A crushing ratio and crusher technology, applied in grain processing and other directions, can solve the problems of easy excessive crushing, easy blockage of materials, reduction of crushing efficiency and processing capacity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

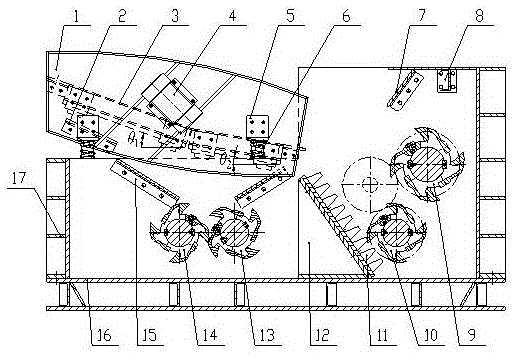

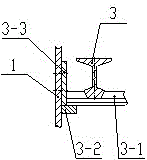

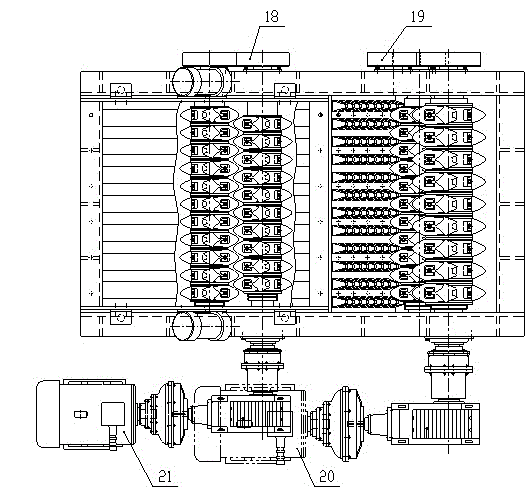

[0020] Such as figure 1 and image 3 As shown, the mine-used differential high crushing ratio four-roller tooth crusher of the present invention comprises a pinion roller drive device 21, a driving pinion roller 13, a driven pinion roller 14, a pinion roller shaft transmission gear 18, The first-stage crushing chamber composed of the coal retaining plate 3 15, the base 16 and the box 17 is composed of a large-toothed roller shaft driving device 20, a driving large-toothed roller 9, a driven small-toothed roller 2 10, a transmission gear 19, a toothed plate 11, The secondary crushing chamber composed of the tooth plate support 12, the second coal retaining plate 7 and the base 16; Connected by bolts; the tooth plate 11 is connected with the tooth plate support 12 by bolts, and the tooth plate support 12 is connected with the base 16 by bolts;

[0021] It also includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com