Upward medium-length hole non-coupling charging structure and application method

An application method and charging technology, applied in the field of mining, can solve the problems of limited bending performance of bamboo strips, affecting other operations in the mine, and low working efficiency of workers, achieving less preparation time for charging, shortening preparation time for charging, and reducing The effect of wasting blasting energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

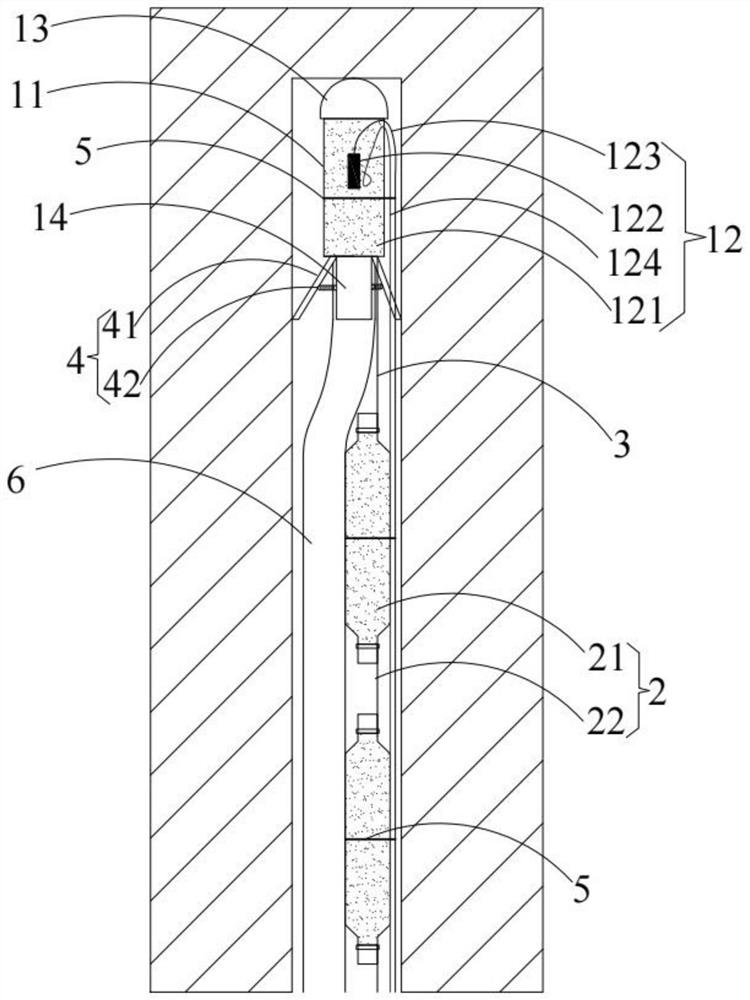

[0037] The present embodiment provides an application method of the uncoupled charge structure for the upward medium-deep hole, which includes the following steps:

[0038] S1. Use ropes to connect strip-shaped explosives 21 with a diameter of 50mm, a length of 200mm, and a string of end-to-end explosives 21 according to the required number of blast holes and a distance of 60mm, and tie them between the detonator shell 11 and the positioning socket 14;

[0039] S2, set the detonator 122 inside the detonating charge column 121, and put it into the detonator shell 11 together, the detonating tube 123 is connected to the detonator 122, one end of the detonating cord 124 is inside the detonating charge column 121, and the other end is connected to the detonating charge column 121 through the adhesive tape 5. All strip-shaped explosives 21 are fixed; at the same time, the detonating tube 123 and the detonating cord 124 are fixed to the outside of the detonator shell 11 with tape 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com