Microfluidic chip based on pneumatic micro pumps and micro mixer

A technology of microfluidic chips and pneumatic micropumps, which is applied in the direction of instruments, laboratory appliances, chemical instruments and methods, etc., can solve the problems of multiple reagents, time, consumption, etc., and achieve the effect of efficient mixing and accurate automatic liquid transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

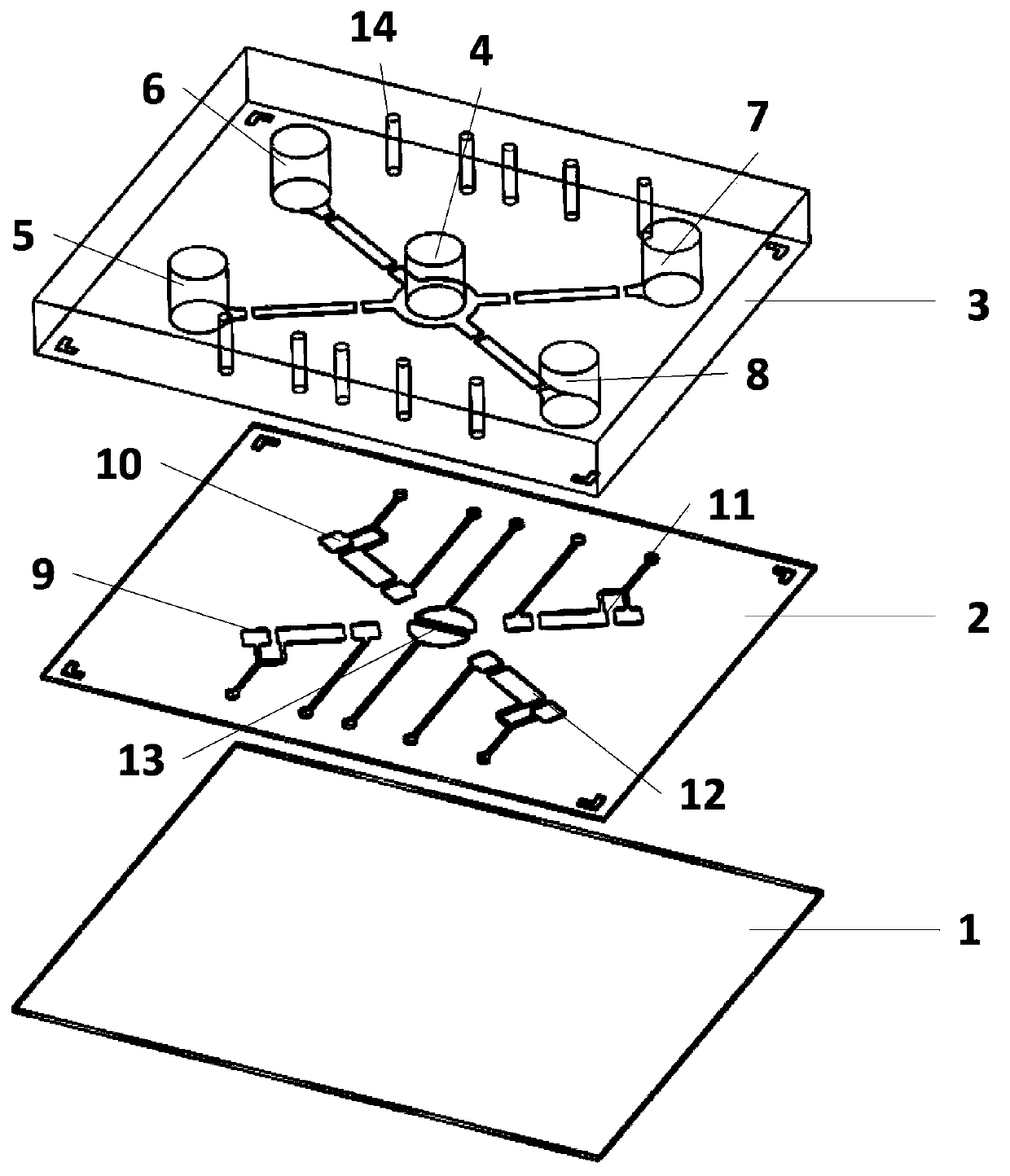

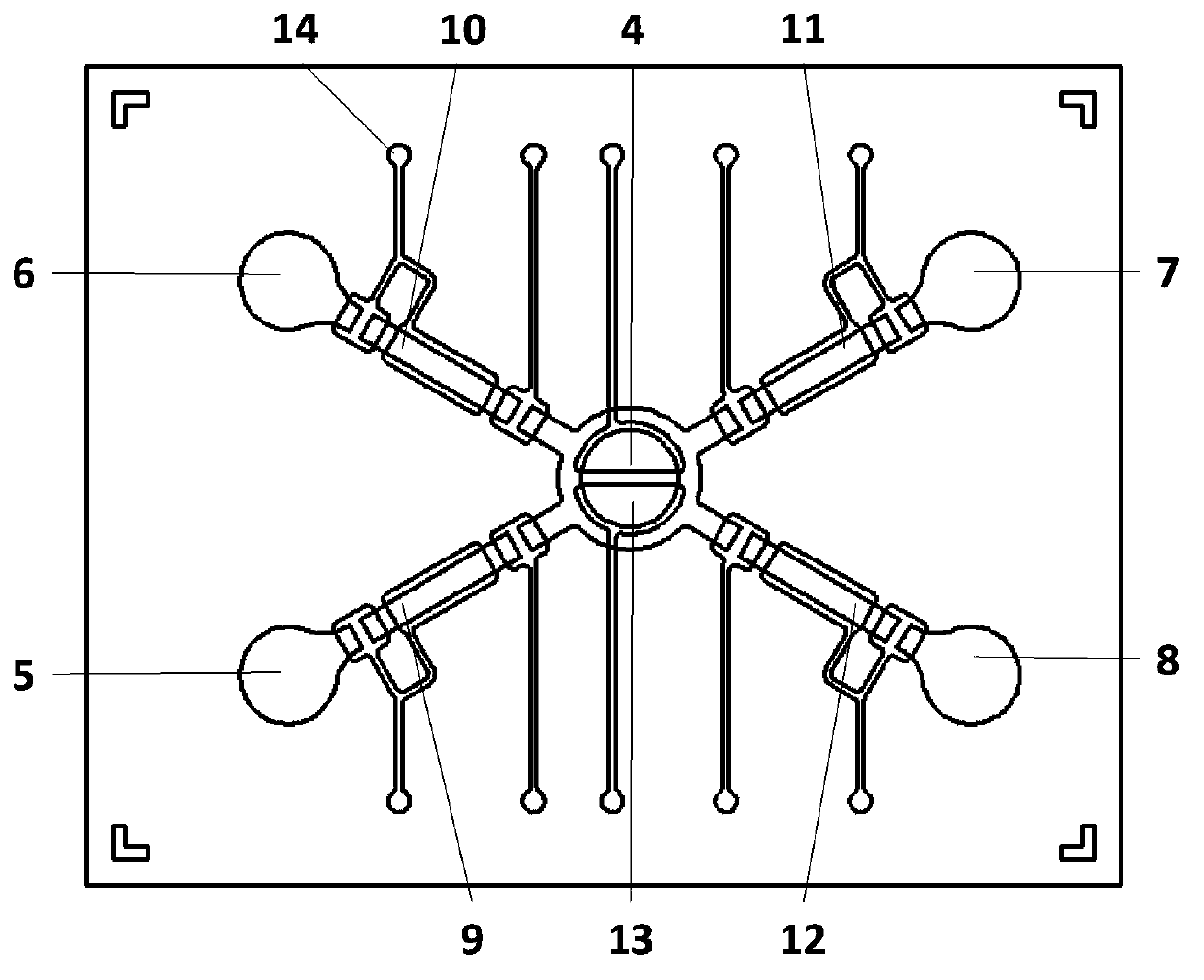

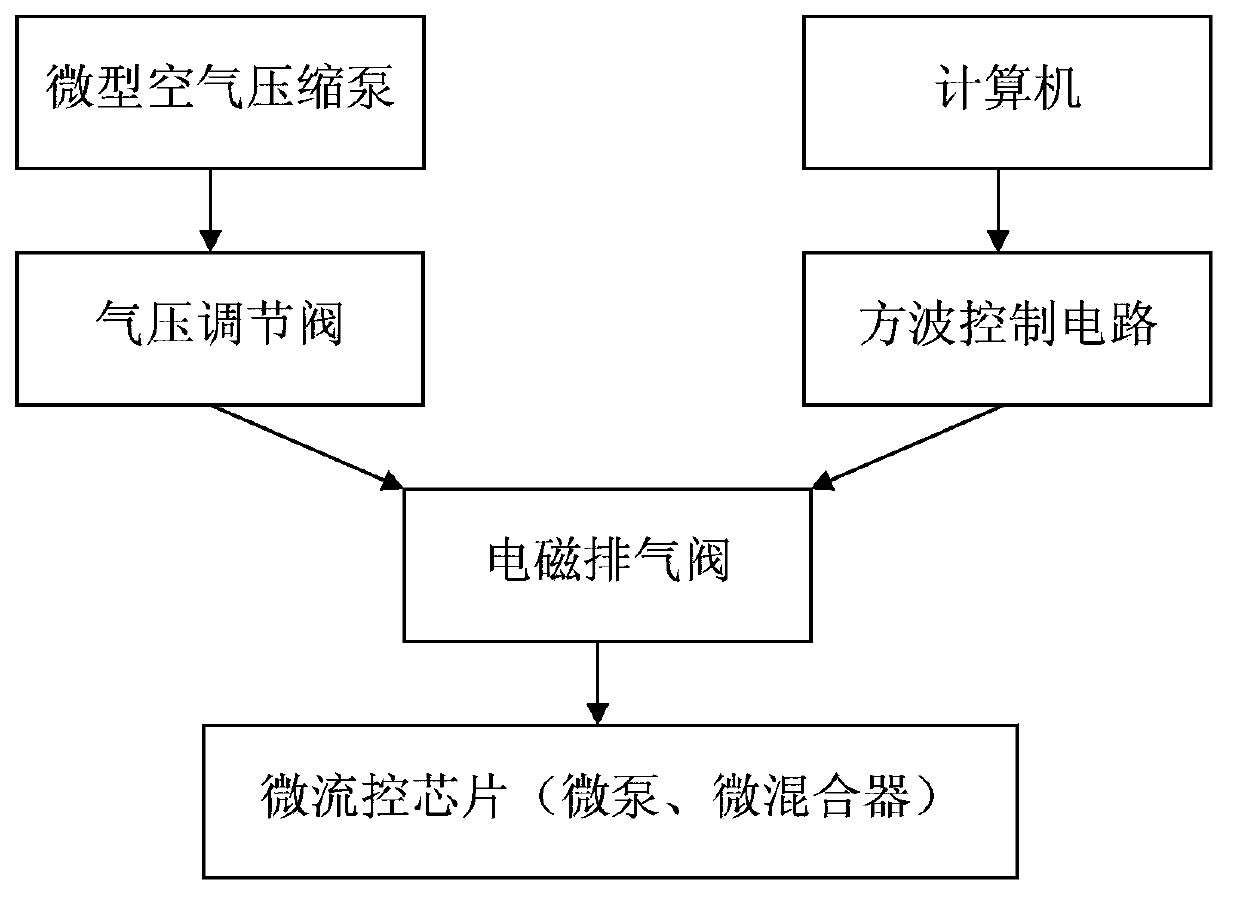

[0025] Such as figure 1 As shown, it is a schematic diagram of the three-layer structure decomposition of the microfluidic chip of the present invention. It is a microfluidic chip based on a pneumatic micropump and a micromixer. The microfluidic chip adopts a three-layer structure. Layer 2 and liquid flow layer 3; wherein, the lower surface of the gas driving layer 2 includes a micro-mixer 13 composed of an air chamber, and a plurality of pneumatic micro-pumps and gas passages are distributed around it; the liquid flow layer 3 includes a micro-mixing chamber 4 , a plurality of micro-reservoirs and the fluid channels connected thereto, the number and distribution position of the pneumatic micro-pumps correspond to the number and position of the fluid channels of the liquid flow layer 3 up and down; the additional pulse air pressure is controll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com