New dispensing equipment

A batching equipment and a new type of technology, applied in mixer accessories, dissolving, mixers and other directions, can solve the problems of internal raw material viscosity increase, influence, raw material solidification and other problems, and achieve the effect of avoiding viscosity increase, easy use and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

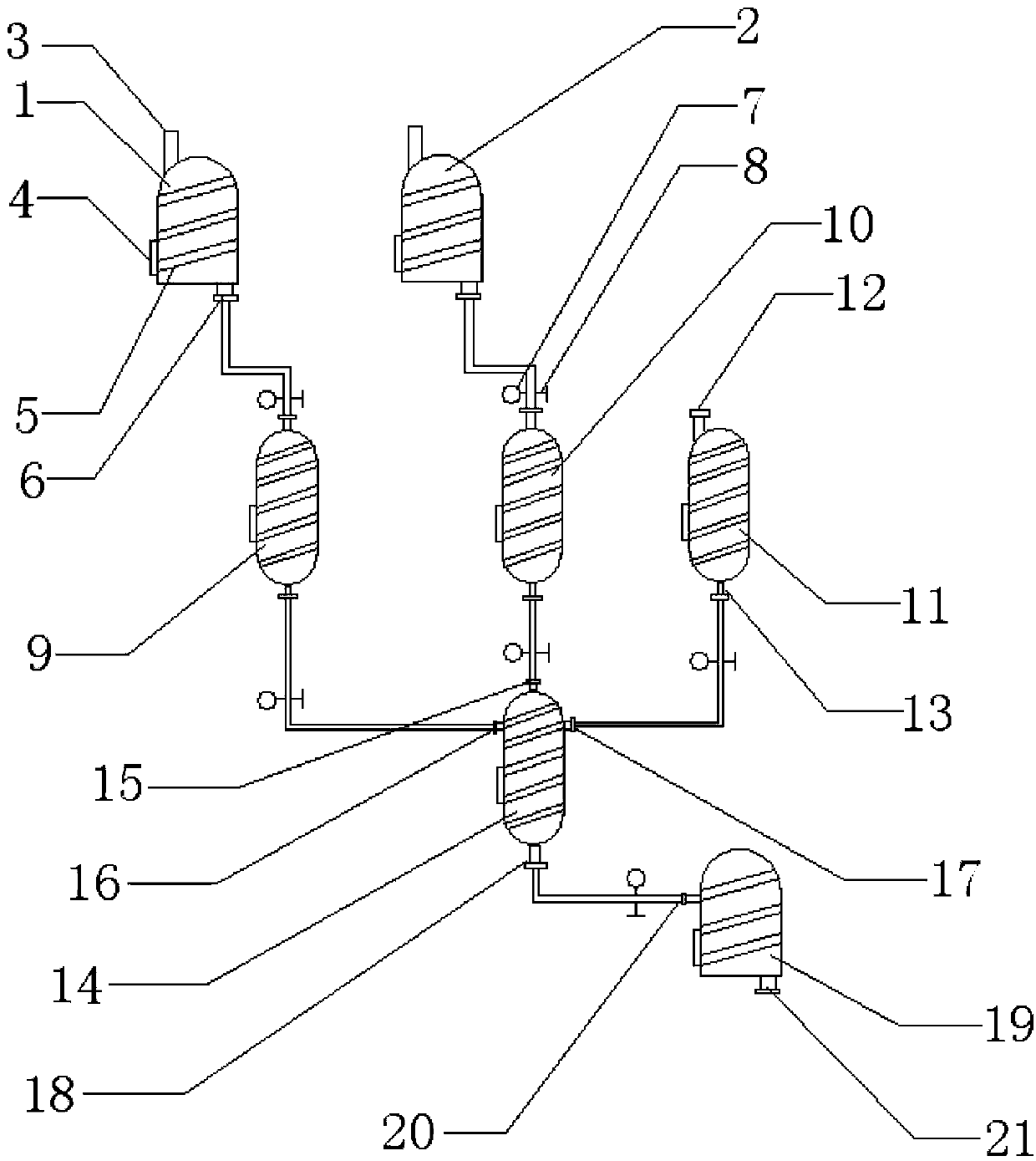

[0009] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0010] A kind of new batching equipment as shown in the figure, comprises preparation tank group, delivery tank group, mixing tank 14 and total storage tank 19, and described preparation tank group comprises residual oil wax paste preparation tank 1 and lubricating oil material preparation tank 2; The top of any tank body in the preparation tank group is provided with a raw material input port 3, and the bottom end of any tank body in the preparation tank group is provided with a raw material output port 6; the delivery tank group includes a residual oil wax paste delivery tank 9, a lubricating oil Delivery tank 10 and concentrated sulfuric acid delivery tank 11; any tank top of the delivery tank group is provided with a material delivery inlet 12, and any tank bottom end of the delivery tank group is provided with a material deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com