Method for preparing cigarette paste of electric heating non-combustion cigarettes

A non-combustible cigarette, electric heating technology, applied in tobacco, tobacco processing, application, etc., can solve the problems of lack of richness, lack of tobacco aroma, etc., to achieve the improvement of aroma richness, meet the taste needs, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

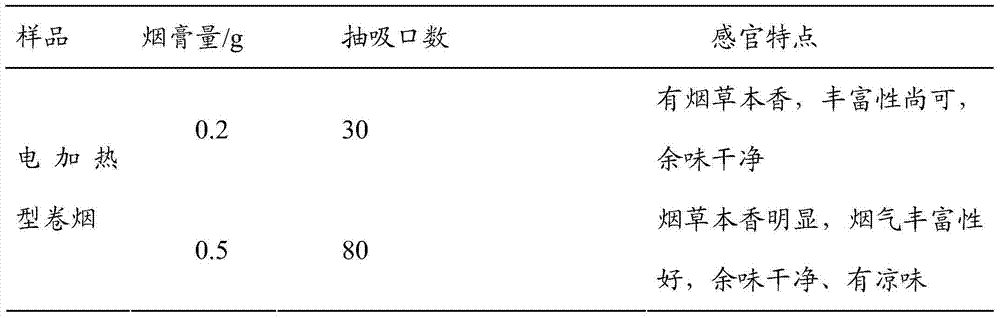

Examples

Embodiment 1

[0023] The preparation method of the electrically heated non-combustible cigarette paste described in this embodiment comprises the following steps:

[0024] (1) Preparation of tobacco essential oil: Weigh 100g of tobacco leaf fragments, put them into 95% ethanol for rough extraction for 3 hours, concentrate and obtain primary tobacco oil, and then evaporate at a temperature of 200-230°C and a vacuum of 0.1Pa , Carry out molecular distillation under the conditions of sample injection temperature 80°C, flow rate 10ml / min, rotation speed 600r / min, condensation temperature 35-45°C, and residue holding temperature 100-120°C, and collect heavy components as tobacco essential oil for later use;

[0025] Wherein, the relative density d of the tobacco essential oil 20 20 is 0.9538, and the refractive index is 1.4985;

[0026] (2) Preparation of cumin oil: Weigh 100g of cumin, put it into 300mL of 95% ethanol for extraction for 3 hours, concentrate to obtain cumin oil, and set aside;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com