Making method for benzo(a)pyrene content reduced ginseng processed product and ginseng processed product made by the same

A manufacturing method and technology of benzopyrene, applied in the field of ginseng manufactured products, can solve the problems of reducing the content of benzopyrene in red ginseng and black ginseng, safety issues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]

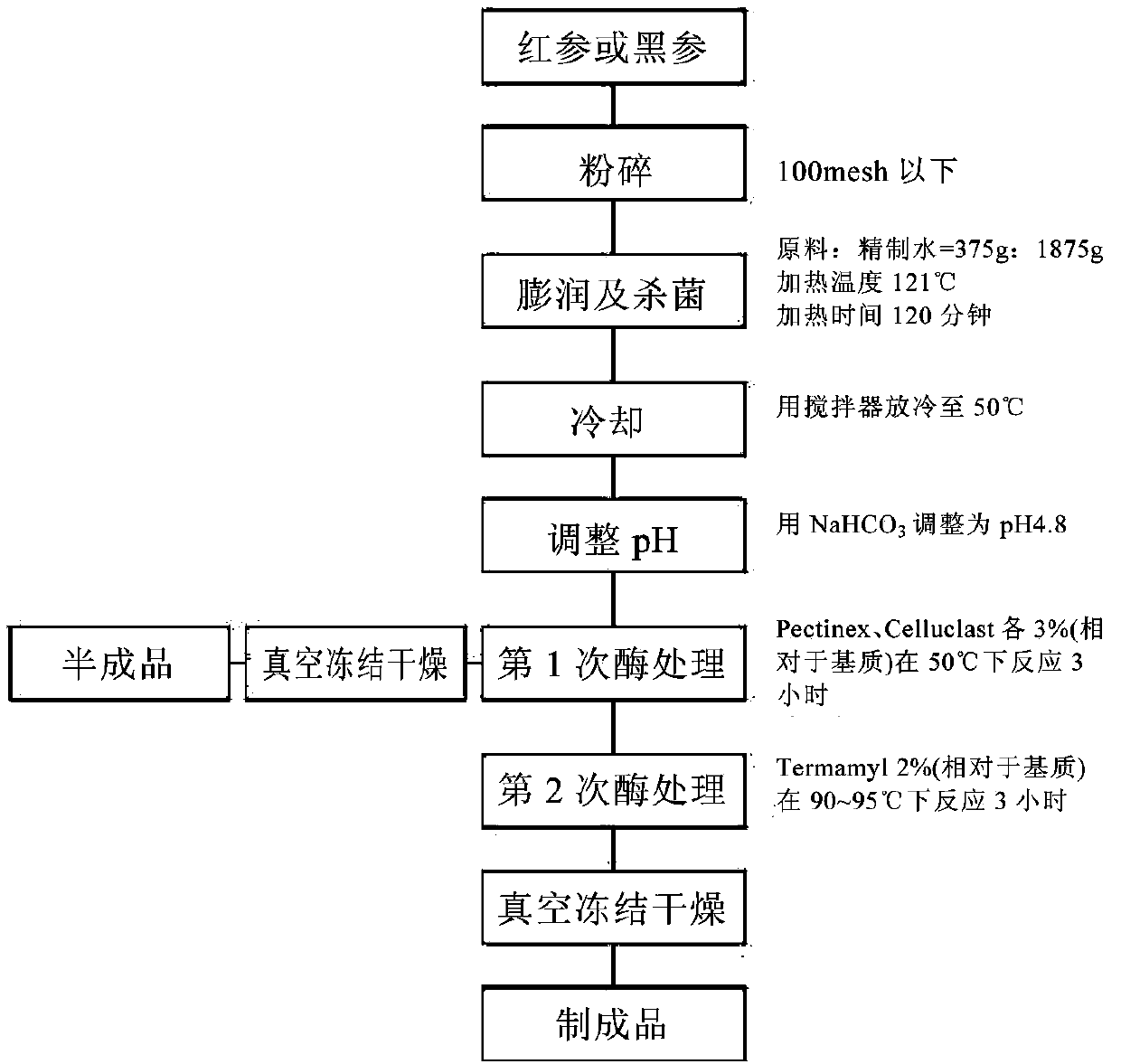

[0037] The manufacture method of the inventor's ginseng artifact such as figure 1 Proceed as shown. Crush the raw material of red ginseng or black ginseng, mix the powder sample passing through a 100mesh sieve: purified water at a ratio of 375g: 1,875g, and then swell and sterilize it in a 121°C sterilizer for 2 hours, then use a mixer Stir and let cool to 50°C. Use NaHCO to cool the sample 3 After adjusting the pH to 4.8, add 3% (w / w) of pectinase (trade name Pectinex, purchased from Novozyme Korea) and cellulase (trade name Celluclast, purchased from Novozyme Korea) to the substrate, and mix thoroughly , Enzyme treatment was carried out at 50° C. for 3 hours.

[0038] Part of it was vacuum freeze-dried to produce a semi-finished product (hereinafter referred to as a semi-finished product), which was used as a sample for investigating changes in the content of benzo(a)pyrene, which is a hazard factor, during the enzyme treatment process.

[0039] The rest of th...

Embodiment 2

[0040]

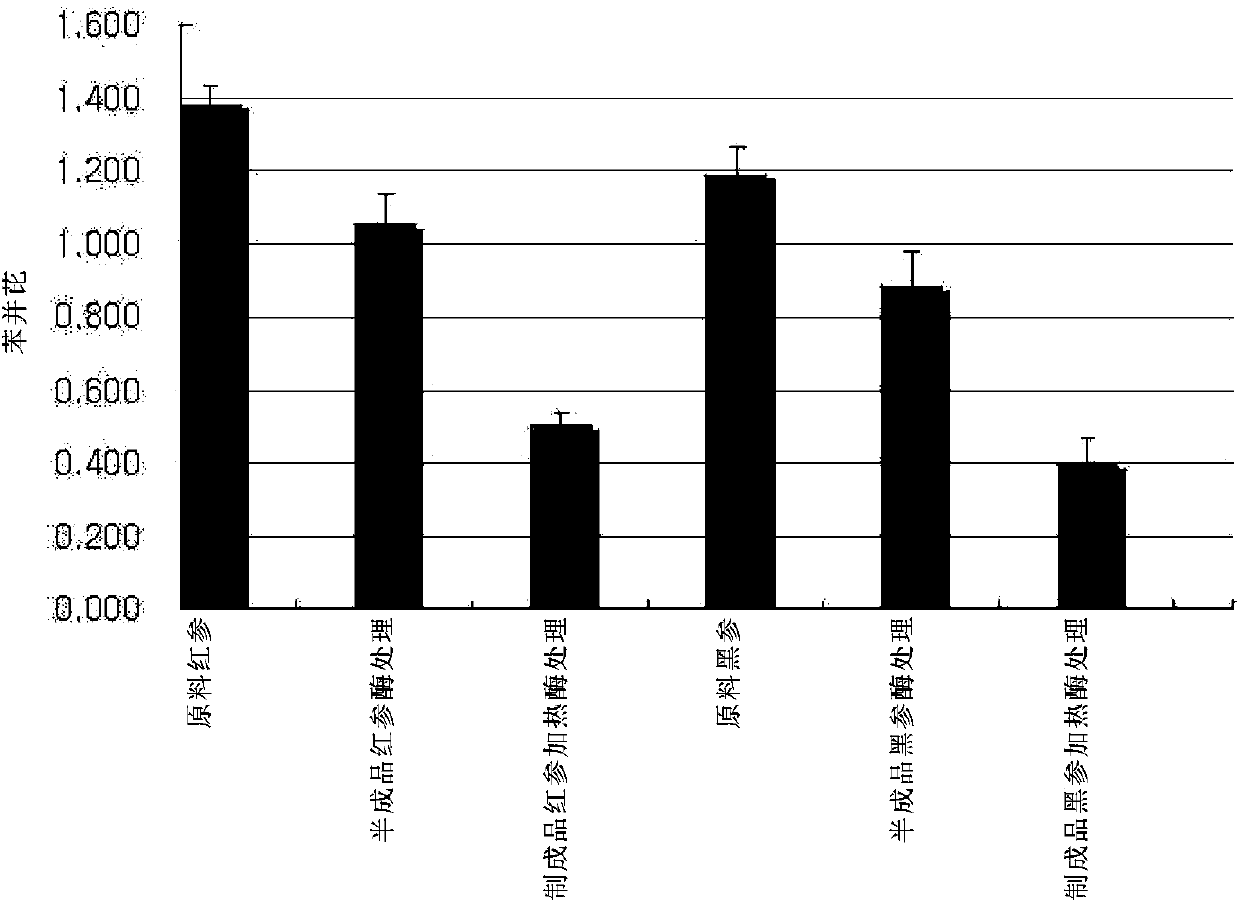

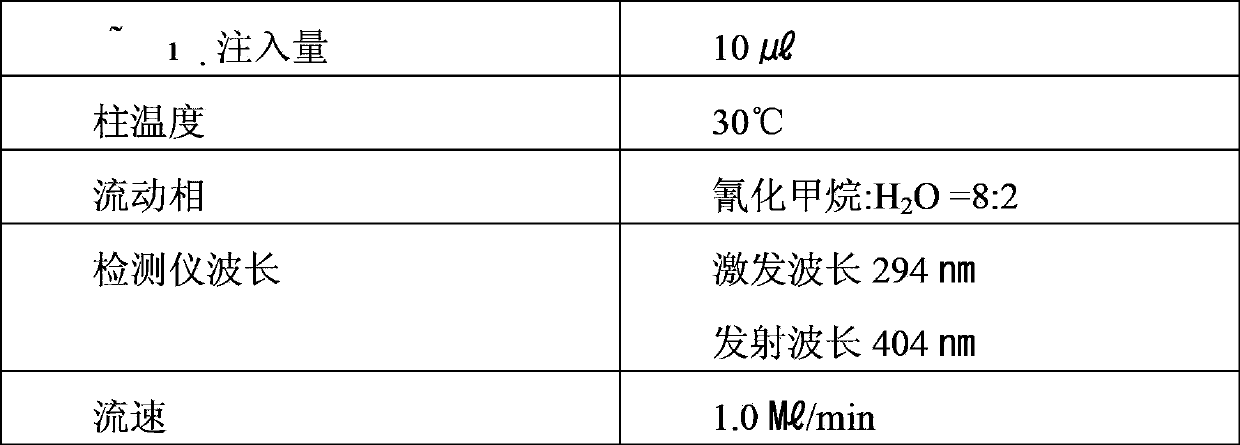

[0041] The content analysis of benzo(a)pyrene in raw materials, semi-finished products and finished products, according to the Ministry of Food and Drug Safety (2007) "Guidelines for the test method of benzo(a)pyrene in health-care functional foods (so-called black ginseng) (2007.12. 31)" Experiments were carried out as follows.

[0042] The extraction of benzo(a)pyrene from the sample is carried out as follows: Accurately weigh 5 g of the sample, add 1 ml of internal standard substance, add about 50 ml of dichloromethane, mix uniformly for 20 minutes, and use ultrasonic extraction at room temperature for 10 minutes . The extraction solution was dehydrated and filtered using No. 6 filter paper added with anhydrous sodium sulfate, and then extracted and concentrated twice, and then mixed with dichloromethane. The mixed dichloromethane was dried under reduced pressure in a water bath at 30°C, and about 2 ml of hexane was added to completely dissolve it, and then used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com