Low-power-consumption chip level atomic clock physical packaging device

A chip-level atomic clock and packaging device technology, applied in the direction of automatic power control, electrical components, etc., can solve problems such as power consumption, and achieve the effects of reducing power consumption, easy implementation, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

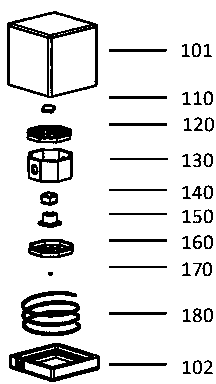

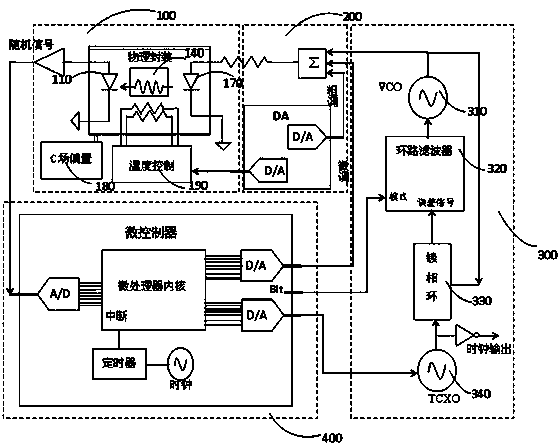

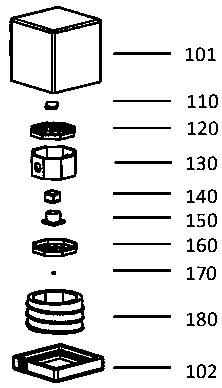

[0026] Embodiment one: see figure 2 As shown, it is a block diagram of an overall system of a chip-level atomic clock, which mainly includes two main parts of a physical package 100 and an electronic circuit. where the physical package 100 can be found in figure 2 As shown, it mainly includes ceramic package 101, photodetector 110, upper bracket 120, frame spacer 130, basic atomic bubble gas chamber 140, CPT resonant cavity 150, 1 / 4 wave plate, lower bracket 160, laser 170, C Field bias module 180 , heating device (ITO thin film) 190 , and base 102 . The alkali metal may be rubidium, cesium or other alkali metals with hyperfine energy level splitting. The C-field bias module 180 can be produced by a coil, a permanent magnet, or a coil and a permanent magnet, see image 3 shown. The C-field bias module 180 in the present invention can be produced by a permanent magnet or by cooperation of a permanent magnet and a coil. This greatly reduces the current through the coil, t...

Embodiment 2

[0030] Embodiment two: see Figure 4 As shown, permanent magnet poles 181 with different properties can be placed at both ends of the physical package 100 , and the permanent magnets 181 generate a magnetic field along the axial direction of the physical package 100 . The magnetic field can be used to separate each Zeeman magneton energy level, so that the 0-0 magneton energy level transition of the ground state can be used as the transition line of the atomic clock. The magnetic poles 181 shown can be in various shapes such as circular, square, polygonal, and the like. The magnetic poles 181 are placed on both sides of the upper and lower supports 120, 160 of the physical package. If the requirement for the accuracy of the magnetic field is relatively high, we can simultaneously surround the coil 40 outside the frame spacer 130 of the physical package 100 to fine-tune the magnetic field strength.

Embodiment 3

[0031] Embodiment three: see Figure 5 and 6 As shown, the permanent magnet can also be cylindrical 182 or square cylindrical 183 . Cylindrical 182 or square cylindrical 183 permanent magnets can generate a magnetic field along the axial direction of the physical package 100, and the physical package 100 is placed in the cylindrical 182 or square cylindrical 183 permanent magnets. The magnetic field produced by the permanent magnets can realize atomic The individual Zeeman magneton energy levels of hyperfine energy level splitting are separated, thereby satisfying the conditions for the normal operation of the physical package 100 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com