Method for quantitative detection of tobacco lignin by adopting mid-infrared spectroscopy

A technology of infrared spectroscopy and quantitative detection, which is used in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of low lignin content, time-consuming and reagent consumption, difficulty in separation and purification of lignin, etc., and achieves reproducibility. Good performance and accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

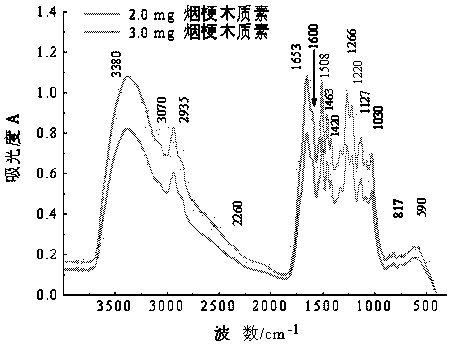

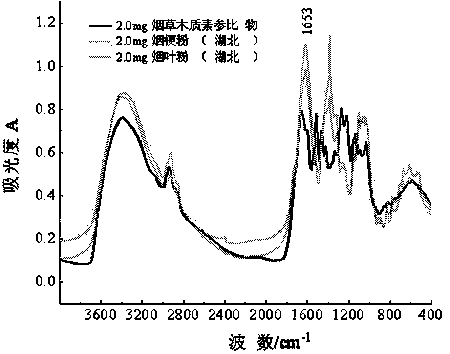

Image

Examples

Embodiment 1

[0041] The tobacco samples used in this example come from tobacco stems, tobacco leaves and characteristic high-quality tobacco leaves B1F (2010) from Sichuan, Hubei and other production areas, sulfuric acid, hydrochloric acid, sodium hydroxide and urea (AR, Guangzhou Chemical Reagent Factory); Potassium (AR). Planetary ball mill (QM-3SP2, Nanjing University Instrument Factory); tablet press (FW-4, Tianjin Tianguang Optical Instrument Co., Ltd.); Fourier transform infrared spectrometer (Nicolet 380, Thermo Company, USA). However, the present invention is not limited thereto, and those skilled in the art may use tobacco samples, reagents and equipment from other sources.

[0042] 1. Sample Processing and Analysis

[0043] According to the method of YC / T 31-1996 "Tobacco and Tobacco Products - Sample Preparation and Moisture Determination - Oven Method", the tobacco stem samples were prepared as tobacco powder samples.

[0044] 2. Prepare the tobacco lignin reference substance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com