Homogeneous rock model with uniaxial compressive strength of 20-30 MPa, and preparation method

A technology with a uniaxial compressive strength of 20-30mpa, which is applied in the field of simulating the compression of homogeneous rock models, can solve the problem that the bonding surface is large, starch-gypsum or peach gum-gypsum binder cannot be selected, and rings cannot be selected. Oxygen resin type adhesives and other problems, to achieve the same effect of the failure form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail in conjunction with the accompanying drawings and embodiments.

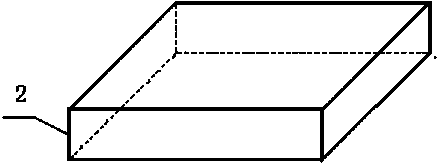

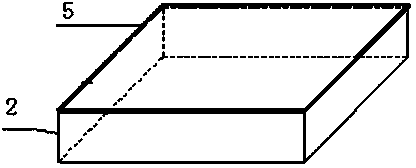

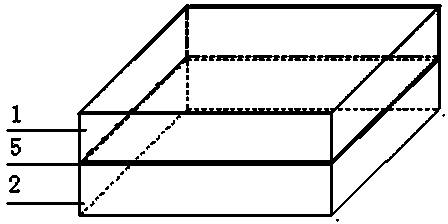

[0043] Such as figure 1 , 2 , 3, and 4, a homogeneous rock model with a uniaxial compressive strength of 20-30 MPa, including: a homogeneous rock upper layer model body 1, a clamping layer 3, a homogeneous rock lower layer model body 2 and a cavern 4. The homogeneous rock upper layer model body 1 is bonded and connected with the homogeneous rock lower layer model body 2 through the clamping layer 3 to form a homogeneous rock model body, and a cylindrical cavity 4 is arranged in the center of the homogeneous rock model body.

[0044] A method for preparing a homogeneous rock model with a uniaxial compressive strength of 20-30 MPa, using a homogeneous rock upper layer model body and a homogeneous rock lower layer model body to form a homogeneous rock model body through a mold layer, and forming a homogeneous rock model body on the homogeneou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com