Electric boosting hydraulic cylinder and boosting method thereof

An electric pressurization and hydraulic cylinder technology, which is applied in the field of hydraulic cylinder manufacturing, can solve the problems of increasing production costs and increasing the complexity of hydraulic cylinders, and achieves the effects of convenient maintenance, simple structure and good boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

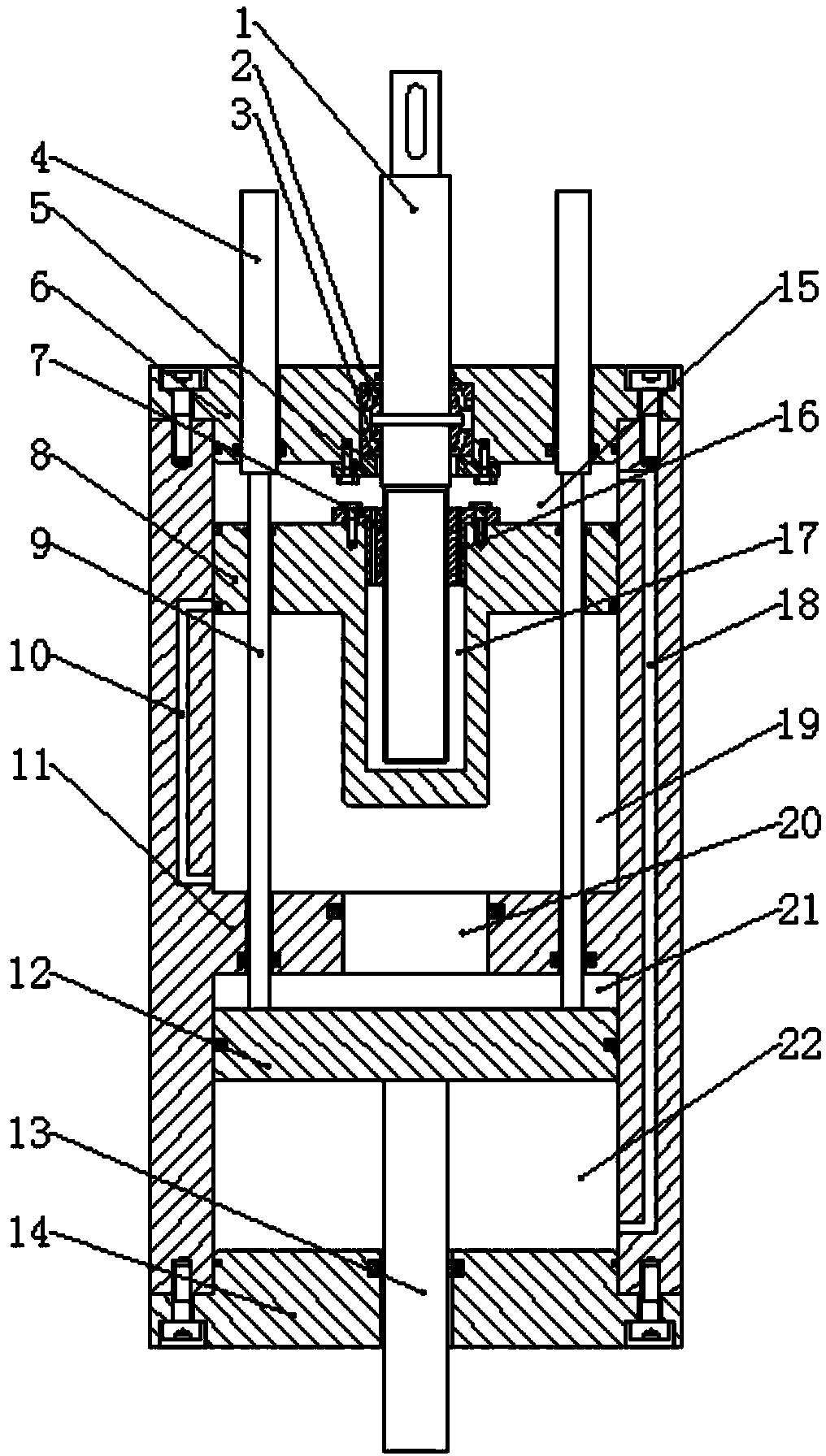

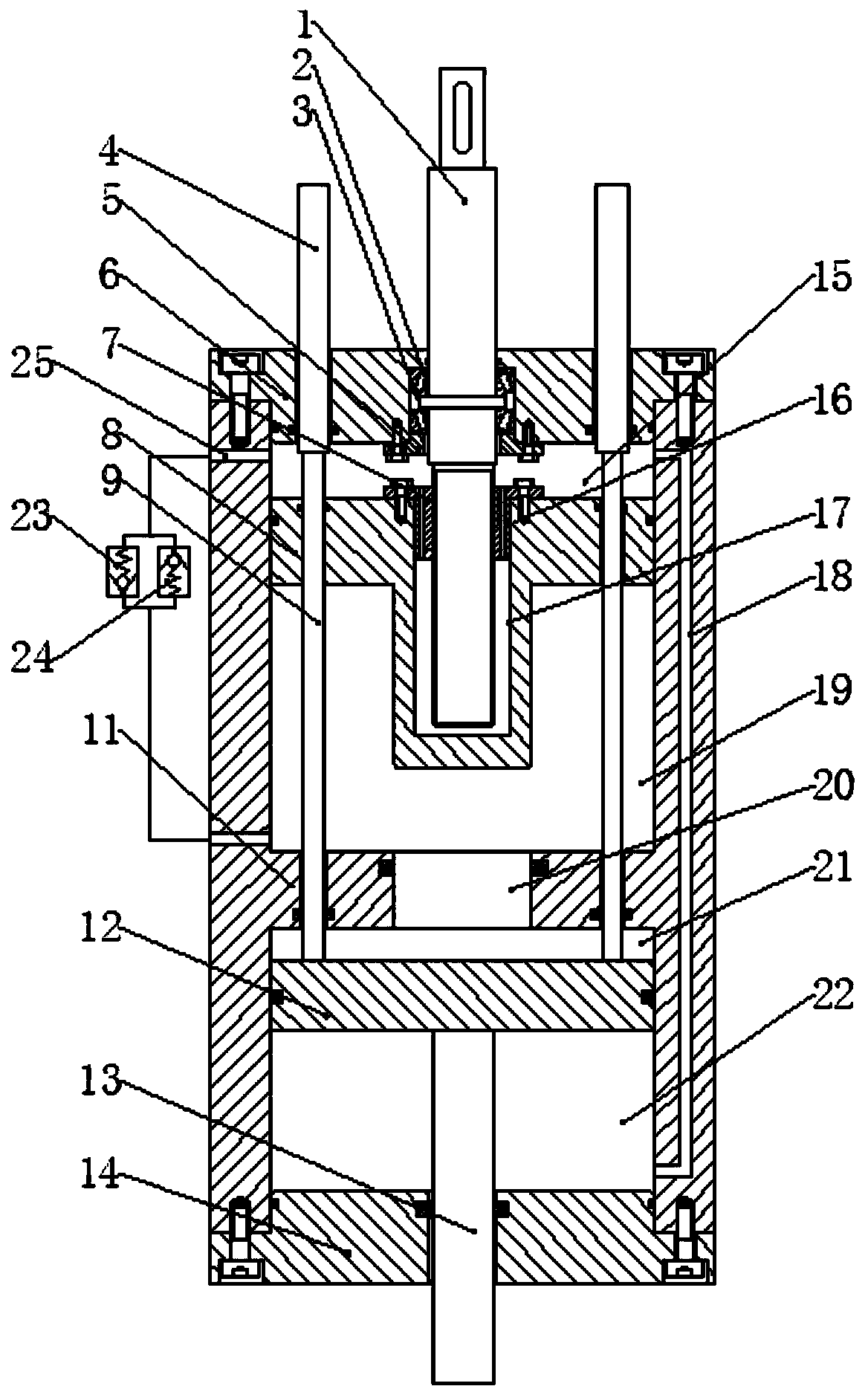

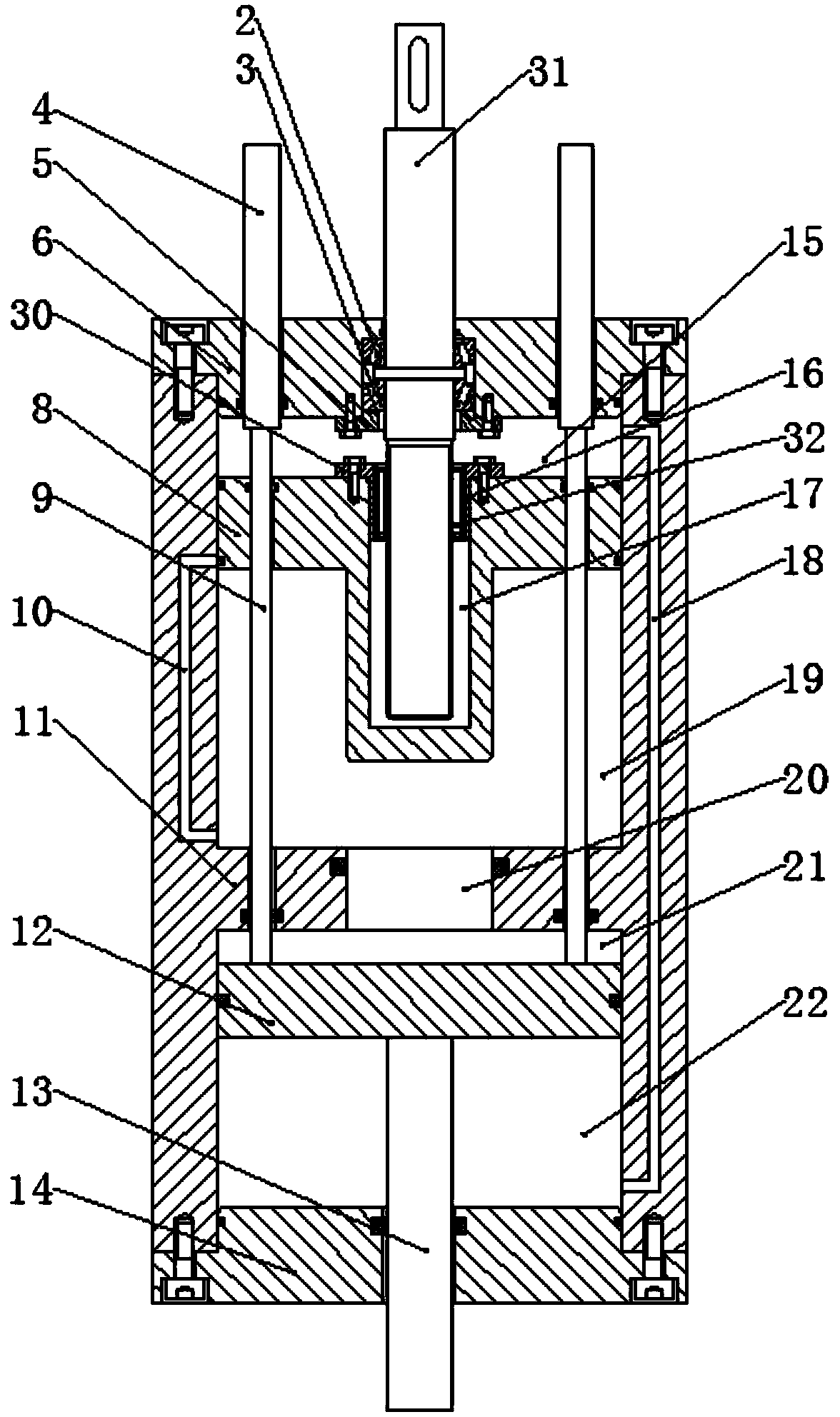

[0025] Such as figure 1As shown, an electric pressurized hydraulic cylinder includes a cylinder body 11, a cylinder head 6 and a cylinder bottom 14 are respectively fixed on the top and bottom of the cylinder body 11 with screws, and the middle part of the cylinder body 11 is provided with a C cavity 20 and a C cavity 20 Connect the upper and lower chambers inside the cylinder 11, the first thickened piston 8 is installed in the upper chamber of the cylinder 11, the second piston 12 is installed in the lower chamber of the cylinder 11, and the ball screw at the bottom of the ball screw 1 The nut 7 and the first thickened piston 8 are connected as a whole through screws or radial fit, the middle part of the ball screw 1 is fixed in the cylinder head 6 through the first thrust bearing 2 and the second thrust bearing 3, and the end cover 5 passes through Screws fix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com