A mechanical bored cast-in-place pile

A technology for mechanical drilling and cast-in-place piles, applied in sheet pile walls, construction, infrastructure engineering, etc., can solve the problems of ineffective cleaning and pouring of sediment, reduced pouring pressure, inaccurate data, etc., and achieve low cost and data. The effect of improved accuracy and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

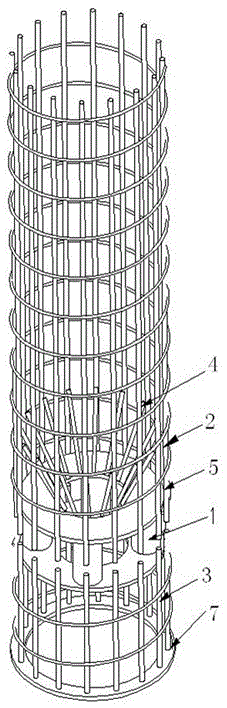

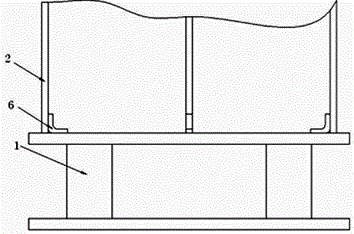

[0021] Attached below figure 1 , 2 The present invention is described in detail:

[0022] A mechanically drilled cast-in-situ pile, which includes a load box 1, an upper steel cage 2 and a lower steel cage 3 respectively connected to the upper end and lower end of the load box 1, and guide ribs are welded between the upper steel cage 2 and the load box 1 4;

[0023] Outer edges of the upper reinforcement cage 2 and the lower reinforcement cage 3 are provided with reinforcement cage outer stirrups 5 , and an annular plate 7 is provided at the lower end of the lower reinforcement cage 3 .

[0024] A right-angled auxiliary reinforcement 6 is provided at the junction of the upper reinforcement cage 2 and the load box 1 . Prevent the reinforcement cage from falling off from the load box during the embedding process.

[0025] The angle between the guide rib 4 and the load box 1 is greater than or equal to 60°. The purpose is to guide the grouting pipe through the center hole of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com