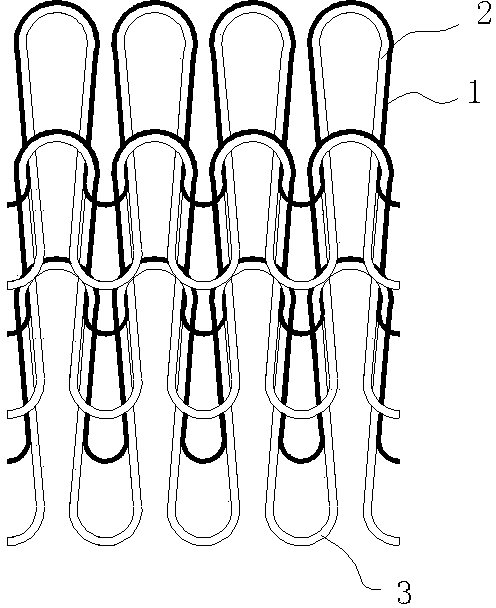

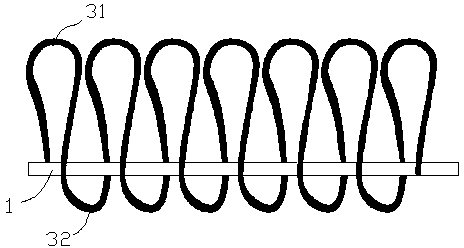

Dual-resistance double-fiber fabric and production method thereof

A technology of fabrics and raw materials, which is applied in the field of double-resistant double fabrics and its production, can solve problems such as uncomfortable wearing, uncomfortable wearing, and difficulty in electric charge dissipation, and achieve the effect of increasing aesthetics, rich styles, and comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Described sweat-absorbing quick-drying agent is the Passerlle of U.S. Dow Corning, and consumption is 3% (O.W.F).

Embodiment 2

[0023] Described sweat-absorbing quick-drying agent is the HSD of U.S. Huntsman, and consumption is 3% (O.W.F).

Embodiment 3

[0025] Include antistatic agent FJ-1, antistatic agent FJ-7, cross-linking agent SL of Japan Rihua in the described antistatic solution, wherein the content of antistatic agent FJ-1 is 5g / L, antistatic agent FJ-7 The content of the cross-linking agent SL is 35g / L, the content of the cross-linking agent SL is 2g / L, and the solvent is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com